Aluminum die casting is one of the most efficient and cost-effective manufacturing methods used to produce complex and precise aluminum components. It involves injecting molten aluminum alloy under high pressure into hardened steel molds (dies), creating parts with consistent dimensions, smooth surface finishes, and excellent mechanical properties.

Today, aluminum die casting is indispensable across multiple industries, including automotive, aerospace, electronics, telecommunications, and industrial machinery. Companies worldwide leverage this technology to manufacture lightweight yet robust parts that enhance performance, reduce costs, and meet demanding market requirements.

With global markets increasingly focused on sustainability and efficiency, aluminum die casting stands out not only for its versatility but also its exceptional recyclability. This combination positions it as a critical manufacturing method for the future, addressing the dual challenges of high performance and reduced environmental impact.

In this guide, you’ll gain comprehensive insights into the aluminum die casting process, alloys used, industry applications, and practical engineering tips.

- Understanding the Die Casting Process

- Common Aluminum Die Casting Alloys and Their Properties

- Aluminum Die Casting Advantages vs. Other Methods

- Essential Design Guidelines for Die Cast Aluminum Parts

- Applications of Aluminum Die Casting Across Industries

- Emerging Trends: Giga Casting and Large Structural Components

- Challenges and Solutions in Aluminum Die Casting

- Finishing and Surface Treatments for Die Cast Parts

- FAQs about Aluminum Die Casting

- Conclusion: Maximizing Value from Aluminum Die Casting

- Juntos hacia la excelencia

Understanding the Die Casting Process

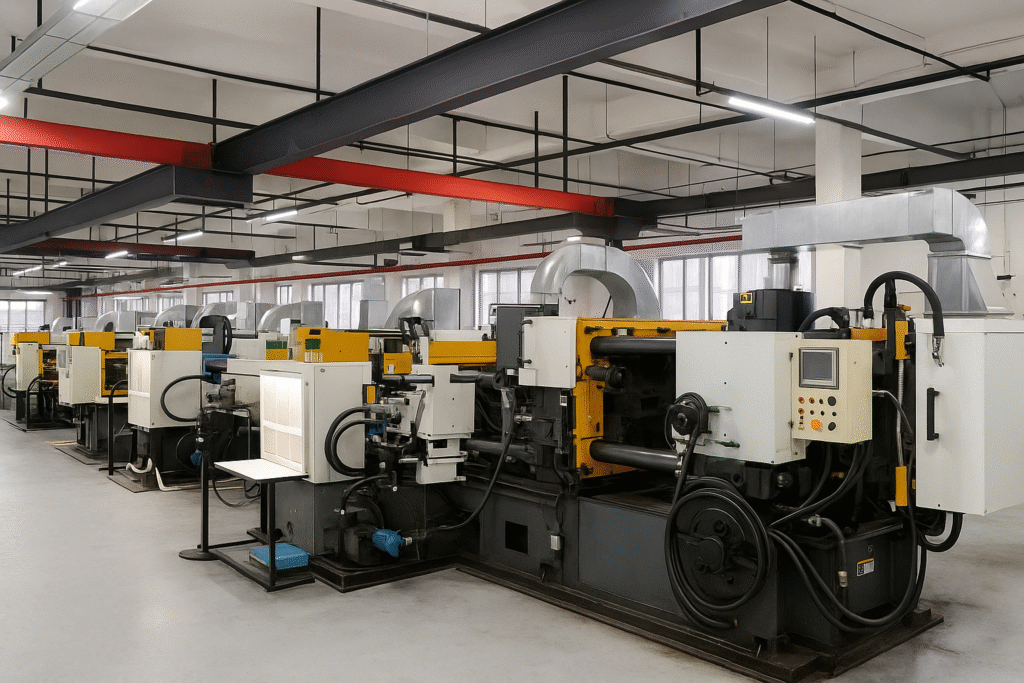

The most prevalent method for aluminum is cold-chamber high-pressure die casting (HPDC), a process necessitated by aluminum’s high melting point, which would damage the machinery in a hot-chamber system. The process is a meticulously controlled sequence of seven primary stages.

![Aluminum Die Casting Process Flowchart Square infographic titled “Aluminum Die Casting Process Flow,” displaying seven numbered steps with line-art icons and arrows:Die Preparation (cleaned, lubricated mold),Melting & Alloy Preparation (furnace and ladle),High-Pressure Injection (spray gun icon),Solidification & Cooling (die with heat waves),Trimming & Finishing (cutting shears),Trimming & Finishing duplicate? [Note: should be step 6],Inspection & Quality Control (checklist and CMM probe),Icons in blue-gray with orange step indicators, arranged in a circular flow.](https://cast-mold.com/wp-content/uploads/2025/07/Aluminum-Die-Casting-Process-Flowchart.jpg)

Step-by-Step Process Breakdown:

Step 1: Die Preparation

The process begins by preparing the die—a reusable, precision-machined steel mold consisting of two halves. Before casting, the die is cleaned and lubricated, usually with a water-based lubricant. Proper lubrication ensures easy part removal, minimizes wear, and prolongs die life.

Step 2: Melting and Alloy Preparation

High-quality aluminum alloys (such as A380, ADC12, A360, etc.) are melted in a furnace at controlled temperatures typically ranging between 680–700°C, slightly above the alloy’s melting point. Precise temperature control is critical to avoid casting defects and ensure good flow properties.

Step 3: High-Pressure Injection

Once molten aluminum reaches the ideal temperature, it’s rapidly injected into the die under pressures ranging from 10 MPa to over 150 MPa. This high-pressure injection ensures the molten metal fills every intricate detail and thin-wall sections of the mold, achieving precise geometries and consistent dimensional accuracy.

Step 4: Solidification and Cooling

Upon injection into the relatively cooler die, molten aluminum begins to rapidly cool and solidify. Proper cooling channels designed within the mold help manage this solidification process efficiently, ensuring uniform shrinkage and dimensional stability of the part.

Step 5: Ejection of Castings

After solidification (usually within a few seconds to minutes, depending on part size and complexity), the die halves open, and the cast component is ejected using strategically placed ejector pins. Proper mold design, including draft angles, helps ensure smooth part removal without damage or distortion.

Step 6: Trimming and Finishing

The ejected part, still attached to gating and runners (excess material), undergoes trimming to remove this extra metal. Depending on quality and surface requirements, further finishing operations such as CNC machining, drilling, tapping, or surface treatments like powder coating or plating might be applied.

Step 7: Inspection and Quality Control

Finally, finished aluminum die castings undergo stringent inspections to verify dimensional accuracy, surface quality, and mechanical integrity. Common inspection techniques include visual checks, dimensional verification with coordinate measuring machines (CMM), X-ray inspection for internal defects, and various mechanical tests (hardness, tensile, fatigue tests).

Process Variants: High-Pressure, Low-Pressure, and Gravity Die Casting

While often used as a monolithic term, “die casting” encompasses several distinct processes, each with a unique balance of speed, cost, and part properties. The choice between them represents a fundamental engineering and economic trade-off.

- High-Pressure Die Casting (HPDC): As the dominant method with over 78% of the market, HPDC is optimized for speed and complexity. Its rapid cycle times and ability to produce intricate, thin-walled parts with an excellent surface finish make it the go-to process for high-volume manufacturing, especially in the automotive industry. However, the high-speed, turbulent fill can trap air, potentially leading to porosity. Furthermore, the rapid solidification creates a microstructure that is generally unsuitable for subsequent solution heat treatment.

- Low-Pressure Die Casting (LPDC): In this method, molten metal is gently forced into the die from a sealed furnace below using low gas pressure (typically 20–100 kPa). The fill is laminar and controlled, significantly reducing turbulence and resulting in denser, less porous castings with higher mechanical integrity. While cycle times are longer and it is less suited for very thin walls, LPDC is ideal for producing robust, pressure-tight parts like wheels or critical structural components that may require heat treatment.

- Gravity Die Casting (Permanent Mold Casting): Here, molten metal is simply poured into the steel mold, filling the cavity under the force of gravity. Tooling is simpler and less expensive than for HPDC. The process is slower, but the gentle fill and slower solidification produce high-integrity castings that are largely free of the porosity associated with HPDC. This makes them excellent candidates for heat treatment to achieve superior mechanical properties. It is often chosen for lower production volumes or when maximum strength is the primary requirement.

Common Aluminum Die Casting Alloys and Their Properties

Selecting the appropriate aluminum alloy is crucial to achieving optimal results in aluminum die casting projects. Each alloy presents distinct properties that influence castability, mechanical strength, corrosion resistance, machinability, and surface finish. Here we detail five commonly used aluminum die casting alloys, highlighting their properties and ideal applications.

1. A380 Aluminum Alloy

- Melting Range: 538–593°C (1000–1100°F)

- Key Properties:

- Exceptional fluidity, ideal for intricate and thin-walled components.

- Good strength-to-weight ratio.

- Excellent corrosion resistance.

- Typical Applications:

- Automotive components (engine blocks, transmission housings).

- Electronics housings.

- Power tools and hardware components.

3. A360 Aluminum Alloy

- Melting Range: 550–610°C (1022–1130°F)

- Key Properties:

- Enhanced corrosion resistance.

- High pressure tightness, suitable for fluid-carrying components.

- Typical Applications:

- Automotive oil pans and pump housings.

- Marine hardware.

- Fluid power systems and industrial equipment.

5. B390 Aluminum Alloy

- Melting Range: 510–595°C (950–1100°F)

- Key Properties:

- Outstanding wear resistance due to high silicon content.

- Limited ductility and moderate castability.

- Typical Applications:

- Automotive brake components.

- Cylinder liners and compressor components.

- Specialized industrial machinery parts.

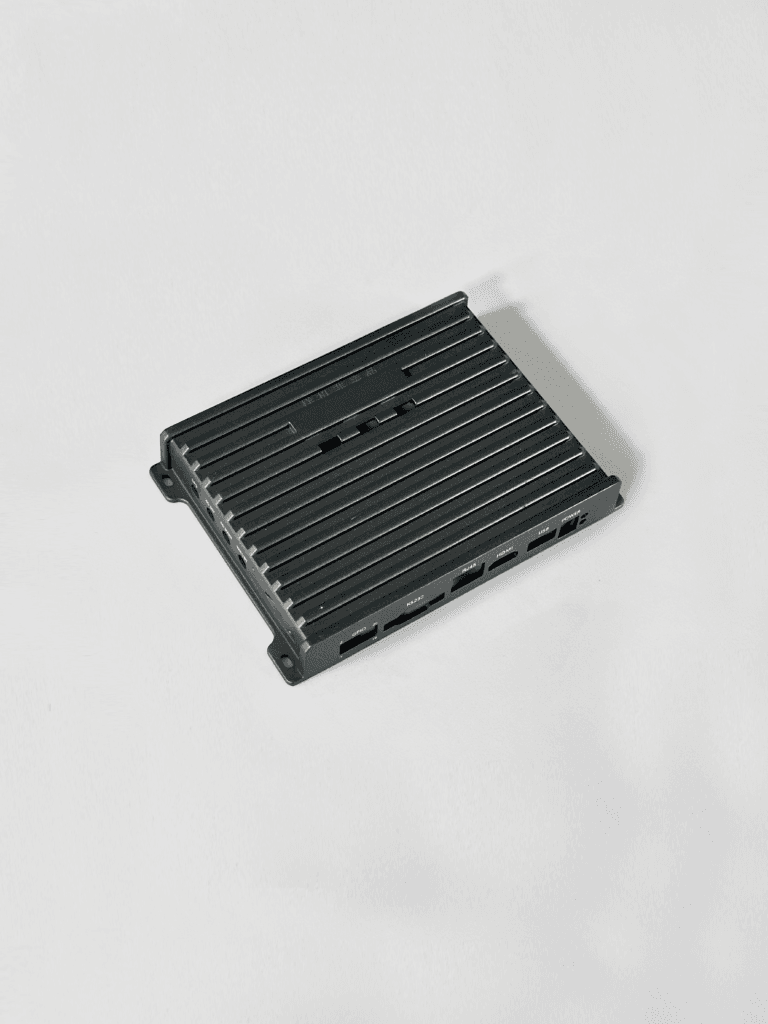

2. ADC12 Aluminum Alloy

- Melting Range: 570–610°C (1058–1130°F)

- Key Properties:

- Superior die-filling capability, particularly popular in Asian manufacturing markets.

- Good mechanical properties and dimensional stability.

- Typical Applications:

- Consumer electronics enclosures.

- Automotive parts such as engine mounts, brackets.

- Telecommunications and computing equipment casings.

4. A413 Aluminum Alloy

- Melting Range: 560–610°C (1040–1130°F)

- Key Properties:

- Excellent pressure tightness and low porosity.

- Very good castability and machinability.

- Typical Applications:

- Hydraulic valve bodies and manifolds.

- Gas regulator housings.

- Complex automotive and aerospace components.

Summary Table: Aluminum Die Casting Alloy Comparison

| Alloy | Melting Range (°C) | Fluidity | Strength | Corrosion Resistance | Maquinabilidad | Ideal Use |

|---|---|---|---|---|---|---|

| A380 | 538–593 | Alta | Bien | Excelente | Bien | Automotive, Electronics |

| ADC12 | 570–610 | Alta | Bien | Bien | Excelente | Electronics, Automotive |

| A360 | 550–610 | Medium | Medium | Excelente | Bien | Marine, Fluid Systems |

| A413 | 560–610 | Alta | Medium | Very Good | Excelente | Hydraulic Systems |

| B390 | 510–595 | Low | Alta | Moderado | Moderado | Wear-Resistant Parts |

Explore our detailed guide on Aluminum Alloys for Die Casting for deeper insights.

Aluminum Die Casting Advantages vs. Other Methods

Aluminum die casting competes with other manufacturing processes such as sand casting, permanent mold casting, CNC machining, and forging. Let’s explore why aluminum die casting frequently emerges as the preferred solution, and when alternative methods might be more suitable.

Advantages of Aluminum Die Casting

- Speed and Efficiency: Aluminum die casting is ideal for high-volume production, offering rapid cycle times—typically measured in seconds rather than minutes or hours—due to its high-pressure injection and quick cooling.

- Complexity and Precision: Capable of producing complex shapes with intricate details and very thin walls (down to 1 mm or less), aluminum die casting achieves consistent high dimensional accuracy (±0.1 mm tolerances).

- Surface Quality: Die-cast aluminum components often require minimal secondary machining due to superior surface finishes, saving time and reducing costs.

- Cost Effectiveness: While initial tooling costs (dies) can be significant, these are offset in mass production, where per-unit costs significantly decrease.

- Strength and Durability: Aluminum alloys used in die casting offer excellent mechanical properties, suitable for structural applications in demanding industries.

Die casting is vastly superior for high-volume production. It delivers an excellent surface finish (typically better than 125 microinches), tight dimensional tolerances, and extremely fast cycle times. In contrast, sand casting uses a disposable sand mold for each part, resulting in a rougher surface, looser tolerances, and a much slower process. However, the tooling for sand casting (the pattern) is significantly cheaper, making it the ideal choice for prototypes, very low production runs, or for producing extremely large and complex parts where a steel die would be prohibitively expensive.

Fundición inyectada de aluminio vs. Permanent Mold Casting (Gravity)

Die casting is faster and can achieve thinner walls and more intricate details due to the high-pressure injection. Permanent mold casting, which relies on gravity, produces parts with thicker sections and is a slower process. However, its tooling is generally less complex and costly than that for HPDC. The slower, gentler fill of permanent mold casting results in parts that are typically denser, stronger, and less porous, making them well-suited for heat treatment to further enhance mechanical properties—a significant advantage for structural components.

Fundición inyectada de aluminio vs. Forging

Forging shapes solid metal under immense pressure, producing parts with the highest possible strength, ductility, and structural integrity. It is unparalleled for critical, high-stress applications. However, this strength comes at the cost of design freedom; forging is generally limited to simpler geometries and is more expensive than die casting for producing complex shapes. Die casting offers far greater flexibility to create intricate, near-net-shape designs.

Die Casting vs. CNC Machining

- CNC Machining is a subtractive process, starting with a solid billet of metal and cutting away material to create the final shape. It offers exceptional precision and the ability to create highly complex geometries with no upfront tooling investment. This makes it perfect for one-off prototypes and low-volume production runs.

- Die Casting is a near-net-shape process. For high-volume production, its economic advantage is overwhelming. The initial tooling cost is high, but the per-part cost is extremely low because the cycle time is measured in seconds, not hours. It also eliminates the significant material waste inherent in subtractive machining. A project’s volume is the primary determinant; below a certain threshold (typically a few hundred parts), CNC machining is more economical, while above it, die casting becomes exponentially cheaper.

Table 2: Manufacturing Method Comparison: Die Casting vs. Alternatives

| Feature / Method | Die Casting | Fundición en arena | CNC Machining | Forging |

|---|---|---|---|---|

| Cycle Time | Very Short | Medium to Long | Medium to Long | Medium |

| Initial Tooling Cost | Alta | Low | Medium | Alta |

| Unit Cost (High Volume) | Low | Moderado | Alta | Moderado |

| Dimensional Accuracy | Muy alta | Moderado | Muy alta | Alta |

| Surface Finish | Excelente | Rough | Excelente | Moderado |

| Complexity of Parts | Alta | Moderado | Alta | Moderado |

| Mechanical Strength | Good to Excellent | Moderado | Excelente | Excelente |

When to Choose Other Methods

- Sand Casting:

- Preferred for low-volume production, large-sized components, or prototypes due to lower initial investment.

- CNC Machining:

- Ideal for very small batches or custom prototypes where die cost is unjustifiable, or extremely tight tolerances and high-quality surface finishes are required.

- Forging:

- Suited for components requiring the highest possible strength and fatigue resistance, such as critical structural automotive or aerospace components.

For more comparison details, read our comprehensive guide: Die Casting vs. Sand Casting: Which One is Right for Your Project?

Essential Design Guidelines for Die Cast Aluminum Parts

Effective part design is the first and most critical step in ensuring a successful die casting outcome. Adhering to Design for Manufacturability (DfM) principles is not merely a suggestion but a prerequisite for producing high-quality, cost-effective, and defect-free components. These guidelines are direct countermeasures to the physical laws governing molten metal flow and heat transfer.

Critical Parameters for Manufacturability: Wall Thickness, Draft Angles, and Ribs

- Wall Thickness: The single most important design rule is to maintain a uniform wall thickness throughout the part. Non-uniform sections create a fundamental problem in thermodynamics: thick sections cool much more slowly than thin sections. This differential cooling induces immense internal stresses, leading to defects like warping, shrinkage porosity, and hot tears.

- Recommendation: A consistent wall thickness between 2.0 mm and 4.0 mm is optimal for most aluminum die castings. Any transitions between different thicknesses must be gradual and blended with smooth fillets, not abrupt steps.

- Draft Angles: A draft is a slight taper applied to all vertical surfaces of the part that are parallel to the direction of the die’s opening. This is a physical necessity to overcome the immense friction and adhesion that occurs as the cooling part shrinks onto the steel cores of the die.

- Recommendation: A minimum draft of 1° to 3° is required for internal surfaces, with 2° to 5° recommended for external surfaces. Insufficient draft will prevent the part from ejecting cleanly, causing drag marks, distortion, or even catastrophic damage to the part and the expensive die itself.

- Fillets and Radii: Sharp internal corners must be rigorously avoided. From a fluid dynamics perspective, they disrupt the smooth, laminar flow of molten metal, causing turbulence that can trap air and lead to gas porosity. From a structural perspective, they are stress concentrators that create weak points in the final part.

- Recommendation: Use generous fillets (rounded internal corners) and radii (rounded external corners) at all intersections. The radius of an internal fillet should be at least equal to the wall thickness. Even a minimal radius of 0.5 mm to 1.0 mm can significantly improve metal flow and part strength.

- Ribs: Ribs are used to increase the strength and stiffness of a component without adding weight and cost by increasing the overall wall thickness. They must be designed carefully to avoid creating new problems.

- Recommendation: To prevent sink marks on the opposite surface, rib thickness should be limited to approximately 50-60% of the adjoining wall thickness. Rib height should not exceed 2.5 to 4 times the wall thickness to ensure proper filling and avoid distortion. Ribs should be blended smoothly into the main body of the part with fillets and incorporate the same draft as the rest of the part.

Designing for Integrity: Preventing Porosity, Shrinkage, and Cracks

A well-designed part is inherently resistant to common casting defects. The DfM guidelines above are the primary tools for prevention.

- To Prevent Gas Porosity: Design with uniform wall thickness and generous, smooth fillets to promote non-turbulent metal flow. This minimizes the chance of air being churned into the molten aluminum during injection. The part design must also allow the caster to incorporate effective vents and overflows in the die to let trapped air escape.

- To Prevent Shrinkage Porosity: The primary cause of shrinkage is isolated heavy masses of material. The best prevention is to design them out. Core out thick sections to create hollows, maintaining uniform walls. This ensures the entire part cools and solidifies at a more even rate. The gating system, designed by the caster, must also be able to continuously feed molten metal to the last areas to solidify, compensating for the natural volume reduction.

- To Prevent Cracks (Hot Tears): Hot tears are caused by thermal stress during solidification. Generous fillets and radii are the best defense, as they eliminate the sharp corners that act as stress concentration points. The overall design should also avoid features that excessively constrain the part as it cools and shrinks within the die.

Applications of Aluminum Die Casting Across Industries

Aluminum die casting is highly versatile, making it ideal across numerous industries due to its combination of strength, precision, lightweight characteristics, and excellent corrosion resistance. Here we explore specific applications in prominent sectors.

Industria del automóvil

Aluminum die casting is particularly dominant in automotive manufacturing due to its capacity to produce strong yet lightweight components:

- Engine Components: Cylinder heads, engine blocks, intake manifolds, transmission cases.

- Structural Parts: Suspension arms, steering housings, engine mounts.

- Safety Components: Airbag housings, ABS brake housings.

The automotive sector highly values the process’s ability to achieve intricate shapes and thin walls to reduce vehicle weight and improve fuel efficiency.

Aerospace and Aviation

Aerospace demands lightweight materials with exceptional mechanical properties. Aluminum die casting meets these demands:

- Structural Components: Aircraft seat supports, frame connectors.

- Engine Components: Fuel pump housings, gearbox casings, compressor parts.

- Avionics Housings: High precision instrument and sensor housings.

Aluminum’s ability to withstand environmental extremes and reduce overall aircraft weight makes die casting an essential aerospace manufacturing method.

Electronics Industry

Consumer electronics rely heavily on aluminum die casting due to its excellent thermal conductivity, EMI/RFI shielding, and structural precision:

- Device Housings: Smartphones, laptops, tablets, and cameras.

- Heat Management Components: Heat sinks for processors, LED housings.

- Durable, Lightweight Enclosures: Highly precise tolerances and smooth surfaces make die casting preferable to other manufacturing methods.

Telecommunications

Rapid advancement in telecommunications infrastructure necessitates robust, precise, weather-resistant aluminum components:

- 5G Base Stations: Antenna housings, cooling elements.

- Satellite Communications: Components requiring minimal weight and exceptional dimensional accuracy.

- Outdoor Equipment: Weather-resistant, corrosion-resistant aluminum enclosures.

Industrial Machinery and Tools

Industrial equipment manufacturers utilize aluminum die casting for reliable, lightweight, cost-efficient components:

- Tool Bodies and Casings: Lightweight power tools, hydraulic pump bodies, electric motor housings.

- Precision Components: Robotics parts, conveyor systems, complex industrial equipment casings.

Medical Devices

Medical device manufacturing also benefits from aluminum die casting:

- Instrument Housings: Lightweight, corrosion-resistant medical equipment enclosures.

- Diagnostic Equipment: Components requiring high dimensional accuracy and structural integrity.

Industry Application Table:

| Industry | Common Aluminum Die Casting Components |

|---|---|

| Automotive | Engine blocks, transmission housings, suspension parts |

| Aerospace | Seat supports, avionics enclosures, engine components |

| Electronics | Smartphones, laptops, heat sinks, cameras |

| Telecommunications | 5G antenna housings, satellite equipment, weather-resistant enclosures |

| Maquinaria industrial | Hydraulic components, electric motor housings, robotic parts |

| Medical | Medical instrument casings, diagnostic equipment parts |

Emerging Trends: Giga Casting and Large Structural Components

The Tesla-Driven Trend of Integrated Die Casting

A revolutionary shift in automotive manufacturing is underway, pioneered by Tesla and termed “Giga Casting” or “Mega Casting.” This process utilizes enormous high-pressure die casting machines—with clamping forces of 6,000 to 9,000 tonnes and beyond—to produce very large sections of a car’s body structure as a single piece.

For example, Tesla replaced the traditional rear underbody of its Model Y, which was composed of 70 to over 170 individual stamped and welded parts, with just one or two massive aluminum castings. This represents a fundamental paradigm shift away from the century-old practice of stamping and welding. The benefits are transformative:

- Drastic Part Count Reduction: Simplifies the bill of materials and supply chain logistics.

- Simplified Assembly: Eliminates hundreds of welds and the associated robotic assembly stations, dramatically reducing factory footprint, capital investment, and labor costs.

- Improved Structural Integrity: A single casting eliminates numerous joints and seams, which can be potential points of failure or sources of noise, vibration, and harshness (NVH), resulting in a stiffer, more robust, and potentially safer chassis.

- Weight Reduction: Consolidating parts into an optimized cast design can lead to significant weight savings of 10-20%, which is critical for EV range.

Impact on the Future Automotive Supply Chain

Giga Casting is poised to radically disrupt the traditional automotive supply chain. Historically, OEMs relied on a tiered network of suppliers to provide stamped metal sub-assemblies. Giga Casting brings this manufacturing capability in-house for OEMs like Tesla, or shifts the value to a new class of Tier 1 suppliers capable of making the massive capital investment in Giga Presses and the associated technology.

This trend presents both challenges and opportunities. It requires enormous upfront capital expenditure (CAPEX) for the massive presses and tooling. Designing and producing such large, complex castings without defects is a significant technical hurdle. Innovations like using 3D-printed sand molds to prototype and validate the multi-million-dollar steel dies are becoming crucial to de-risk the process. For the broader industry, the adoption of Giga Casting by other major OEMs like Toyota, GM, and Volvo signals that this is not a niche trend but a foundational change in how cars will be built in the future.

Challenges and Solutions in Aluminum Die Casting

Despite its advantages, aluminum die casting is a complex process susceptible to a range of defects. Understanding their causes and implementing effective prevention strategies is key to ensuring part quality and manufacturing efficiency.

Analysis of Common Defects (Porosity, Cold Shuts, Hot Tears)

- Gas and Shrinkage Porosity: Porosity, appearing as small internal voids, is one of the most common defects. Gas porosity is caused by air or gas becoming trapped in the molten metal during the turbulent injection phase or being released from the metal itself as it cools.Shrinkage porosity occurs because aluminum shrinks in volume as it solidifies. If insufficient molten metal is available to fill these voids in the last areas to cool (typically thick sections), cavities will form. Porosity critically weakens the part, impairs pressure tightness, and acts as a stress concentrator.

- Cold Shuts and Misruns: These defects occur when the molten metal cools too quickly and fails to completely fill the die cavity, or when two fronts of flowing metal meet but are too cool to fuse together properly. This leaves a linear flaw or weak spot on the part. Causes include low melt or die temperature, insufficient injection speed, or a poorly designed gating system that restricts flow.

- Hot Tears (Hot Cracking): These are cracks that form in the casting while it is still hot and not fully solidified. They are caused by thermal stresses that arise when the part’s natural shrinkage is constrained by the rigid steel die, particularly around features with high stress concentrations like sharp corners.

Defect Prevention and Process Optimization Measures

The most effective approach to defect control is prevention through a combination of robust design, meticulous process control, and advanced technology.

- Design Optimization: As detailed in Section 5, designing for manufacturability is the first line of defense. Uniform wall thickness, generous fillets, and proper draft angles are essential to promote smooth metal flow and uniform cooling, which directly counters the root causes of shrinkage, warping, and hot tears.

- Process Parameter Control: Suppliers must maintain strict control over key variables. This includes optimizing melt and die temperatures, injection pressure and speed, and cooling rates. Using modern die casting machines with real-time process monitoring and closed-loop control is critical for consistency.

- Tooling Design: The design of the die itself is paramount. The gating and runner system must be engineered to ensure a smooth, non-turbulent fill. Vents and overflows must be strategically placed to allow trapped air to escape the cavity before it is engulfed by the metal.

- Melt Quality and Degassing: The molten aluminum must be clean and free of impurities. Degassing systems are often used to remove dissolved hydrogen from the melt before casting, which is a primary source of gas porosity.

- Simulation: Advanced mold-flow simulation software allows engineers to model the entire injection and solidification process digitally before cutting steel. This can predict and help eliminate potential defects like air entrapment, cold shuts, and porosity, saving significant time and cost in tooling modifications.

Finishing and Surface Treatments for Die Cast Parts

While die casting produces parts with an excellent, near-net-shape finish, most components require some form of post-processing to meet final dimensional tolerances, enhance appearance, or improve functional properties like corrosion or wear resistance.

CNC Machining and Surface Preparation

- CNC Machining: For features requiring tolerances tighter than what die casting can achieve, or for creating features that are impossible to form in the die (like undercuts or perpendicular holes), secondary CNC machining is employed. This provides the final, precise dimensions for critical mating surfaces, threads, and bores.

- Surface Preparation: Processes like shot blasting or sand blasting are used to remove any residual flash, create a uniform matte texture, and prepare the surface for subsequent coatings.

Common Surface Treatments: Anodizing, Powder Coating, and Plating

The choice of surface treatment depends on the part’s aesthetic and functional requirements.

- Powder Coating: This is one of the most popular finishes for aluminum die castings. A dry powder is electrostatically applied to the part and then cured under heat to form a hard, durable, and protective layer. It offers excellent resistance to scratches and corrosion and is available in a wide variety of colors and textures.

- Anodizing: This electrochemical process grows a controlled layer of aluminum oxide on the part’s surface. This oxide layer is very hard, corrosion-resistant, and electrically insulating. It can also be dyed to produce a range of decorative colors. However, it’s important to note that the high silicon content in many die casting alloys can result in a less uniform, often grayish appearance compared to anodized wrought aluminum.

- Chem Film (Chromate Conversion Coating): This is a chemical treatment that creates a thin protective film on the aluminum surface. It provides good corrosion resistance and, critically, maintains electrical conductivity, making it a common choice for electronic enclosures and components where grounding is required.

- Plating: Processes like nickel or chrome plating can be applied to provide a very hard, wear-resistant, and decorative finish, though they require specific preparation steps to ensure proper adhesion to the aluminum substrate.

FAQs about Aluminum Die Casting

This is a common point of confusion. The answer depends critically on the specific casting process used. Standard high-pressure die castings (HPDC) are generally NOT suitable for full solution heat treatment (like a T6 temper). The high-speed, turbulent injection process traps microscopic gas bubbles within the metal matrix. When the part is later heated to the high temperatures required for solution treatment (e.g., above 500°C), this trapped gas expands, causing surface blisters and internal voids that destroy the part’s integrity. However, parts produced by slower, less turbulent methods like gravity die casting, sand casting, or specialized low-porosity/vacuum-assisted HPDC are indeed heat-treatable. These processes yield denser castings that can safely undergo treatments like T5 (artificially aged), T6 (solution treated and artificially aged), and T7 (solution treated and stabilized) to significantly improve their strength, hardness, and ductility.

There is no single “best” alloy; selection is a multi-factor optimization. The decision should balance four key areas:

Mechanical Requirements: What are the strength, hardness, and ductility needs? (e.g., B390 for high wear resistance).

Operating Environment: Will the part face corrosive elements? (e.g., A360 for marine applications).

Functional Properties: Is thermal conductivity, electrical conductivity, or pressure tightness critical? (e.g., A413 for leak-proof components).

Manufacturability and Cost: How intricate is the part? (A highly fluid alloy like A380 is better for complex shapes). What is the target cost? (A380/ADC12 offers the best overall balance of performance and economy). Consulting with the material scientists at your die casting supplier is the best practice for making a data-driven choice.ullamco laboris nisi ut aliquip ex ea commodo consequat.

Yes, but with significant caution and expertise. Weldability is determined by two main factors:

1. Alloy Composition: Most common die casting alloys from the 3xx.x (Al-Si) and 5xx.x (Al-Mg) series are weldable with the correct filler metals (4043 and 5356, respectively). 7xx.x (Al-Zn) alloys are notoriously difficult to weld.

2. Casting Process: This is the more critical factor. Standard die castings are the most challenging to weld due to the internal gas porosity trapped during rapid solidification. When a welding torch heats the material, this trapped gas expands and “outgasses,” creating bubbles and contamination in the weld pool, resulting in a weak and porous joint. Castings made by slower methods like sand or permanent mold casting have far less porosity and are much easier to weld. While die castings can be welded for minor repairs, it is not recommended for primary structural joints.

Conclusion: Maximizing Value from Aluminum Die Casting

Aluminum die casting remains one of the most efficient, cost-effective, and scalable manufacturing methods for producing complex metal parts — particularly in sectors like automotive, electronics, lighting, and industrial machinery.

Maximizing the true potential of aluminum die casting goes far beyond selecting the right process—it depends on early collaboration between your team and an experienced supplier. At CastMold, we specialize in helping engineers and procurement professionals turn complex concepts into high-performance, manufacturable solutions.

By involving CastMold early in your design cycle, you gain access to decades of expertise in aluminum alloys, mold flow simulation, and cost-optimized tooling. Whether you’re developing automotive components, industrial enclosures, or electronics housings, our team is ready to support you with precision from design to delivery.