Have you ever paused mid-email, wondering if you should spell it “aluminium” vs “aluminum”? You’re not alone. Working at CastMold, an expert in aluminum and zinc alloy die casting, I’ve encountered this confusion countless times. Let’s unravel this linguistic mystery and explore how aluminum’s versatility impacts die casting.

Both “aluminium” (British) and “aluminum” (American) are correct. Originating from Sir Humphry Davy’s naming confusion in the early 1800s, “aluminium” aligns with IUPAC’s standardized nomenclature, while “aluminum” persists strongly in North America. Both terms refer to element #13 on the periodic table.

Beyond spelling debates, aluminum’s real-world impact on manufacturing—especially die casting—is profound. Stick around as I cover its history, advantages, disadvantages, and practical uses, and I’ll highlight how CastMold leverages aluminum’s properties through specialized casting and machining processes.

Historical Origins: Sir Humphry Davy’s Naming Drama

It started in 1808 when English chemist Sir Humphry Davy proposed the name “alumium,” derived from the mineral alum. He quickly changed his mind, renaming it “aluminum,” before switching yet again to “aluminium,” aligning it with other “ium” ending elements like sodium and potassium. The U.S. spelling “aluminum” gained popularity after Noah Webster adopted it in his 1828 dictionary. Meanwhile, “aluminium” stuck firmly in British English and throughout Europe.

Historical Timeline:

| Year | Event |

| 1808 | Davy initially proposes “alumium.” |

| 1812 | Davy renames to “aluminum,” then quickly to “aluminium.” |

| 1828 | Webster solidifies “aluminum” in American English. |

| 1990 | IUPAC officially accepts both spellings. |

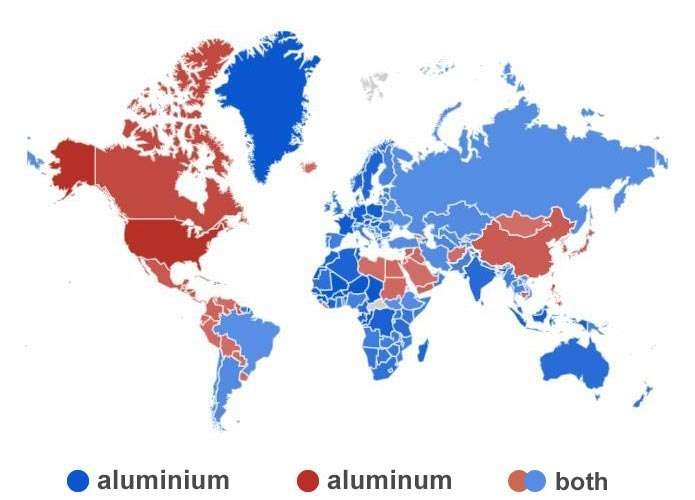

Regional Differences Today: Aluminium vs Aluminum

Today, linguistic boundaries are clear:

- Aluminium: Used in the UK, Europe, Australia, and much of Asia.

- Aluminum: Dominant in the U.S. and Canada.

Both terms correctly reference the same versatile, lightweight metal crucial to industries such as automotive, electronics, aerospace, and telecommunications—industries CastMold regularly serves.

Global Spelling Preference:

| Region | Preferred Spelling |

| United States | Aluminum |

| United Kingdom | Aluminium |

| Canada (mixed usage) | Aluminum/Aluminium |

| Australia/New Zealand | Aluminium |

Are Both Spellings Correct?

Absolutely. Both “aluminium” and “aluminum” are recognized internationally. The International Union of Pure and Applied Chemistry (IUPAC), responsible for naming elements, officially adopted “aluminium” to align with naming consistency. However, recognizing historical usage, IUPAC also accepts “aluminum” as an alternative spelling.

Practical Differences for Die Casting Industry

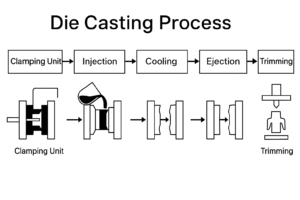

In reality, whether you say “aluminium die casting” or “aluminum die casting,” it refers to exactly the same process: injecting molten aluminum alloys into molds to produce precision components. At CastMold, our expertise covers:

- Aluminum alloy die casting (ADC12, A380)

- Zinc alloy die casting (Zamak series)

- CNC machining

- Surface finishing

Regardless of spelling preferences, the physical properties—density (~2.7 g/cm³), lightweight strength, corrosion resistance, and thermal conductivity—remain identical and are crucial in selecting materials for applications in automotive, electronics, and telecom industries.

Aluminum’s Advantages in Die Casting

At CastMold, aluminum alloy die casting is our core expertise. Here’s why aluminum dominates the industry:

- High Strength-to-Weight Ratio: Ideal for automotive and aerospace parts—lighter cars mean better fuel efficiency.

- Excellent Corrosion Resistance: Great for outdoor or marine environments—think lighting housings, telecom enclosures.

- Superior Thermal Conductivity: Perfect for heat sinks and electronic casings.

- Recyclability: 100% recyclable, aligning with sustainability goals.

For example, automotive transmission housings often use alloys like ADC12 or A380—both staples at CastMold—due to their excellent fluidity, strength, and lightweight nature.

Limitations of Aluminum in Die Casting

Of course, aluminum has its limits:

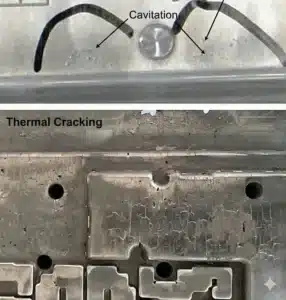

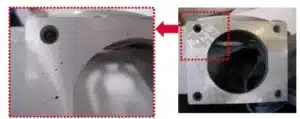

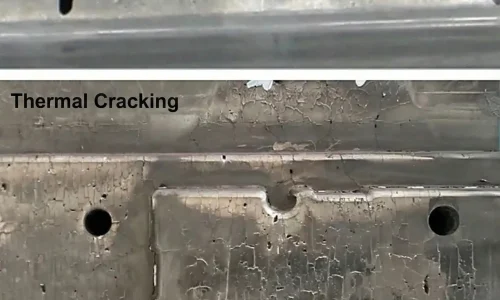

- Higher Shrinkage Rate: Demands precision mold design to ensure dimensional accuracy.

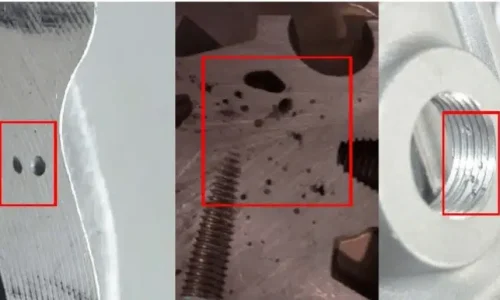

- Surface Porosity Risk: Requires careful control during casting to avoid defects.

- Limited Strength at Elevated Temperatures: May need special alloys or secondary treatments for high-temperature applications.

At CastMold, our experienced team manages these risks by precision mold design, strict casting control, and rigorous quality checks.

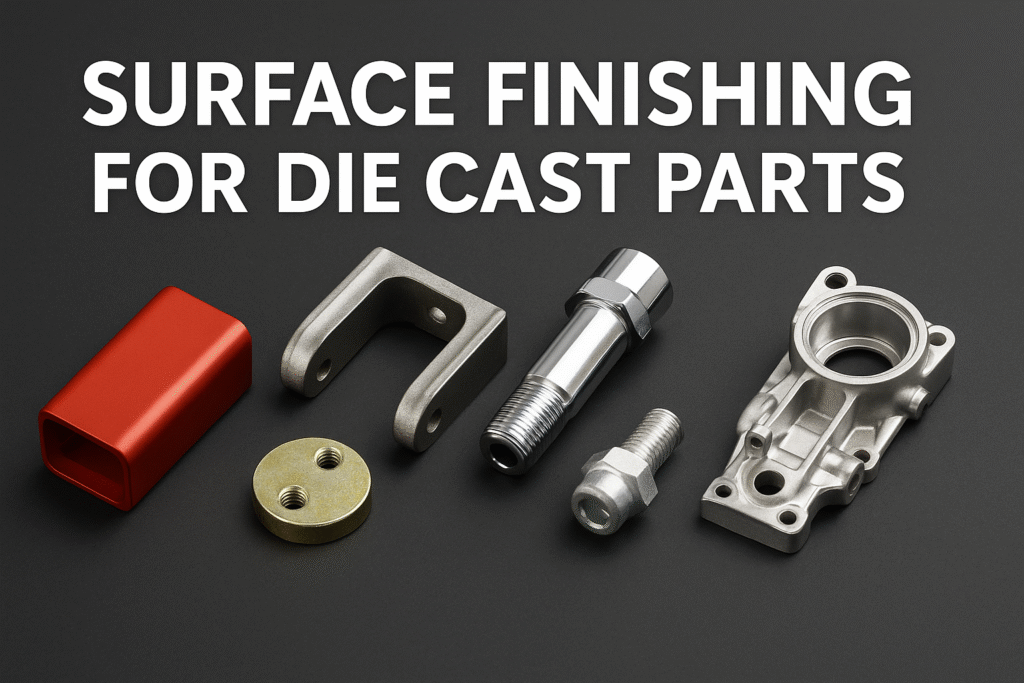

Aluminum Die Casting Surface Treatments

Surface treatments significantly enhance aluminum’s properties. At CastMold, we offer:

- Powder Coating: Provides durability and excellent aesthetics for consumer electronics.

- Electroplating: Enhances corrosion resistance, ideal for telecom components.

- Anodizing: Increases surface hardness and corrosion resistance, popular for automotive trim and fixtures.

- Passivation: Further protects against corrosion, commonly used in outdoor lighting fixtures.

These treatments enhance both functional performance and visual appeal, extending component lifespans dramatically.

CNC Machining & Aluminum Alloys

Many aluminum castings require precise secondary CNC machining, a specialty at CastMold. CNC machining provides:

- High Precision: Achieving tolerances up to ±0.02 mm for demanding electronics and automotive applications.

- Complex Geometry: Milling, drilling, and tapping complex shapes, threads, and holes.

- Superior Finish: Smooth surfaces ideal for subsequent anodizing or powder coating.

This precision ensures parts meet exact specifications, especially for sectors demanding precision like aerospace and medical equipment.

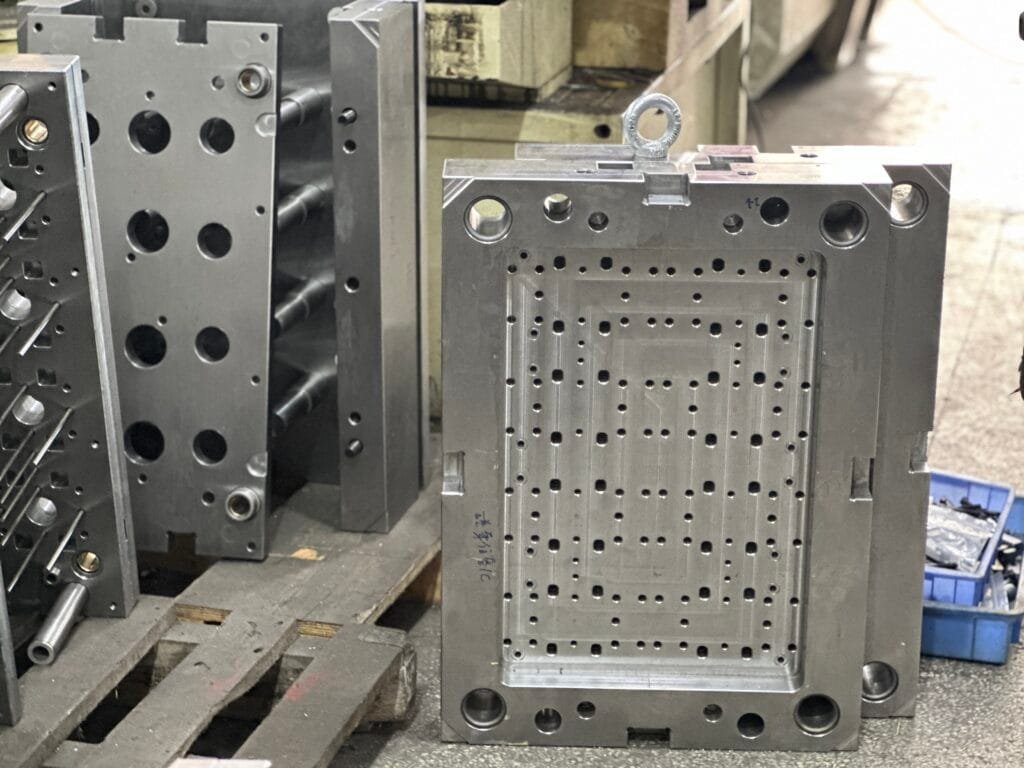

Mold Design and Manufacturing at CastMold

Exceptional aluminum die casting starts with mold quality. Our mold-making capabilities include:

- Precision Tooling: Using durable tool steel like 1.2344 (H13), ensuring longevity and dimensional stability.

- Advanced Software: Employing CAD/CAM software (SolidWorks, Moldflow) to optimize design and casting process.

- Rapid Prototyping: Quick mold adjustments and iterations based on initial casting results.

This comprehensive mold design and manufacturing capability ensures consistent, high-quality die-cast components tailored specifically to customer needs.

Aluminum Die Casting Applications at CastMold

Our aluminum die casting capabilities cover diverse industries:

- Automotive: Engine blocks, transmission housings, structural parts.

- Electronics: Enclosures, heat sinks, connector housings.

- Lighting: LED fixtures, housings, outdoor luminaires.

- Telecom: Antenna housings, brackets, networking casings.

Every CastMold project demonstrates how leveraging aluminum alloys’ density, strength, thermal properties, and machinability directly benefit client products.

Conclusion

While both “aluminium” and “aluminum” are correct—rooted deeply in historical quirks—what truly matters is aluminum’s practical advantage in modern manufacturing. At CastMold, our expertise in alloy selection, precision casting, CNC machining, surface treatments, and mold-making ensures your aluminum parts meet every performance expectation, no matter how you spell it.

So, aluminium or aluminum? At CastMold, we’re fluent in both—and experts in turning either into outstanding die-cast products.