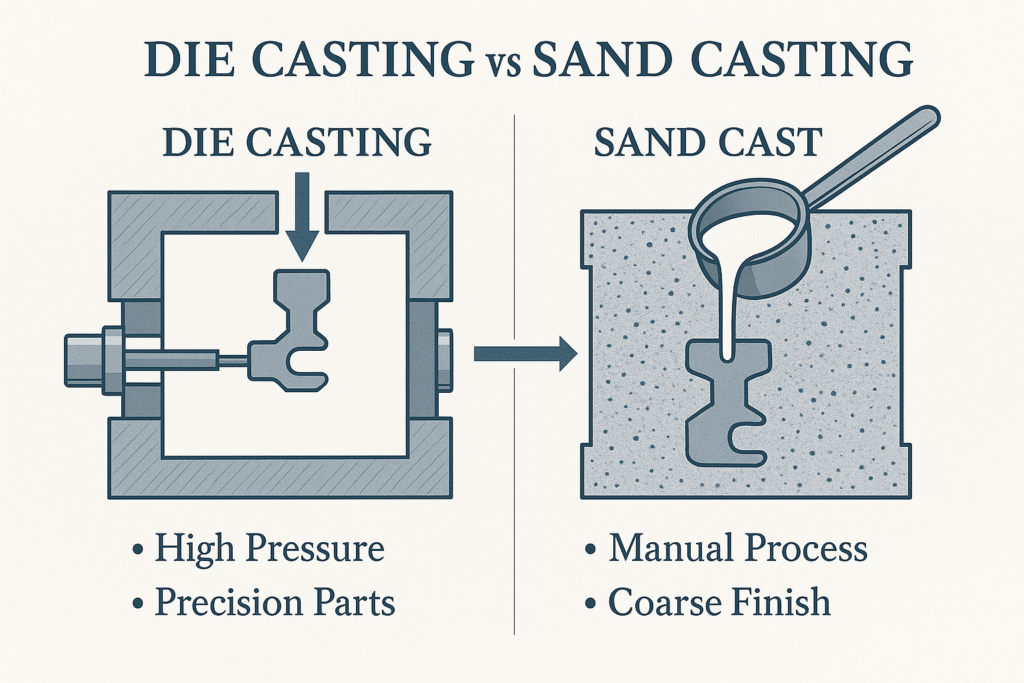

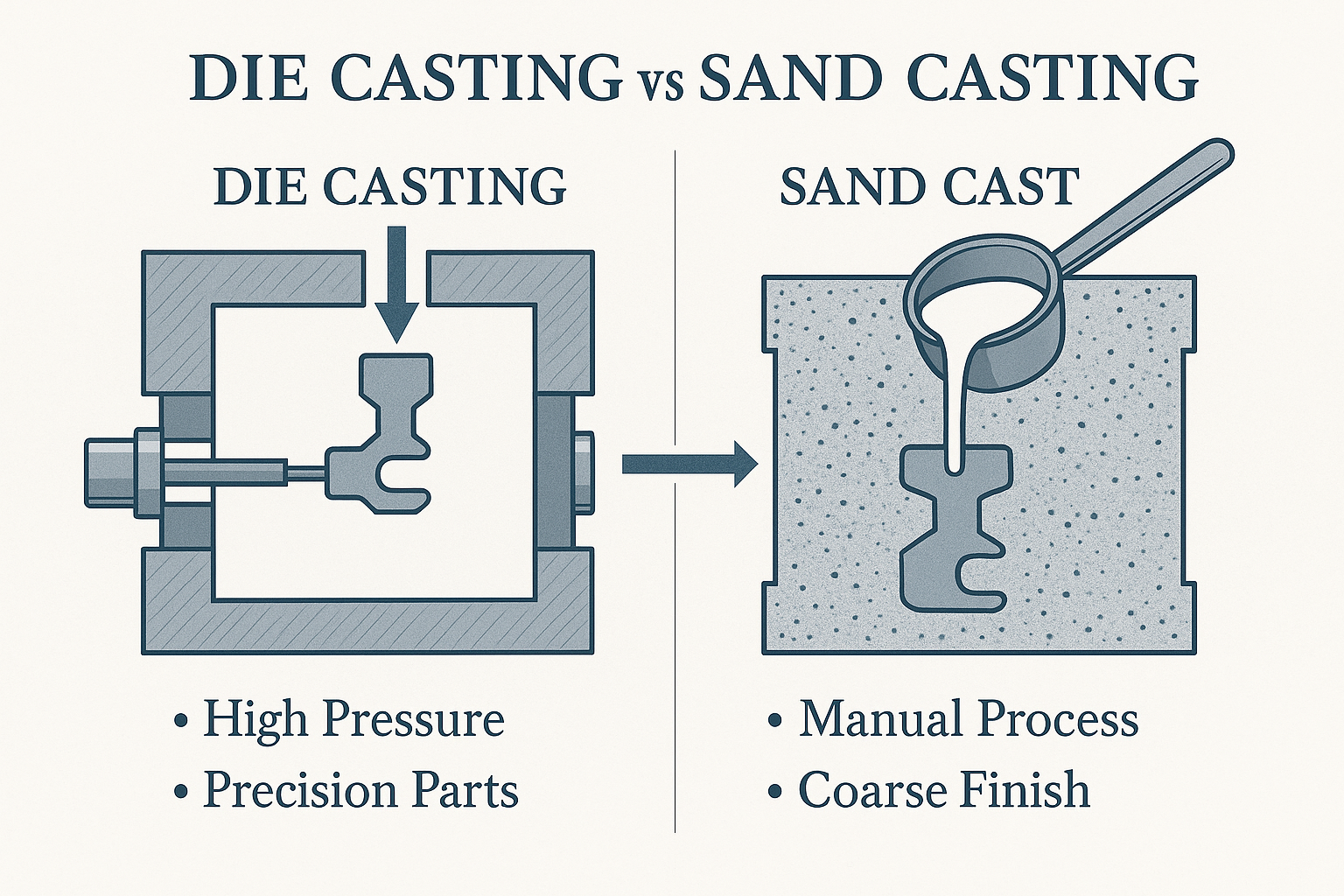

Not all castings are created equal. When it comes to choosing between Die Casting vs Sand Casting, selecting the right metal-forming process is a critical decision that can significantly affect product performance, production efficiency, and overall manufacturing cost. These two methods are among the most established and widely used in the industry—each offering unique advantages depending on your part design, volume, and quality requirements.

While their goal is the same—to shape molten metal—their operating principles and suitable applications are vastly different. Understanding the core differences between die casting and sand casting is the first step toward making informed engineering decisions. This article will delve into both processes to help you make the best choice based on your specific needs, whether for high-volume production or rapid prototyping.

- What is Die Casting? A High-Pressure Approach

- What is Sand Casting? A Versatile and Cost-Effective Method

- Die Casting vs Sand Casting: Head-to-Head Comparison (7 Key Differences)

- Cost Comparison: Die Casting Cost vs Sand Casting Cost

- Precision and Surface Finish: A Clear Winner

- Production Speed and Volume Suitability

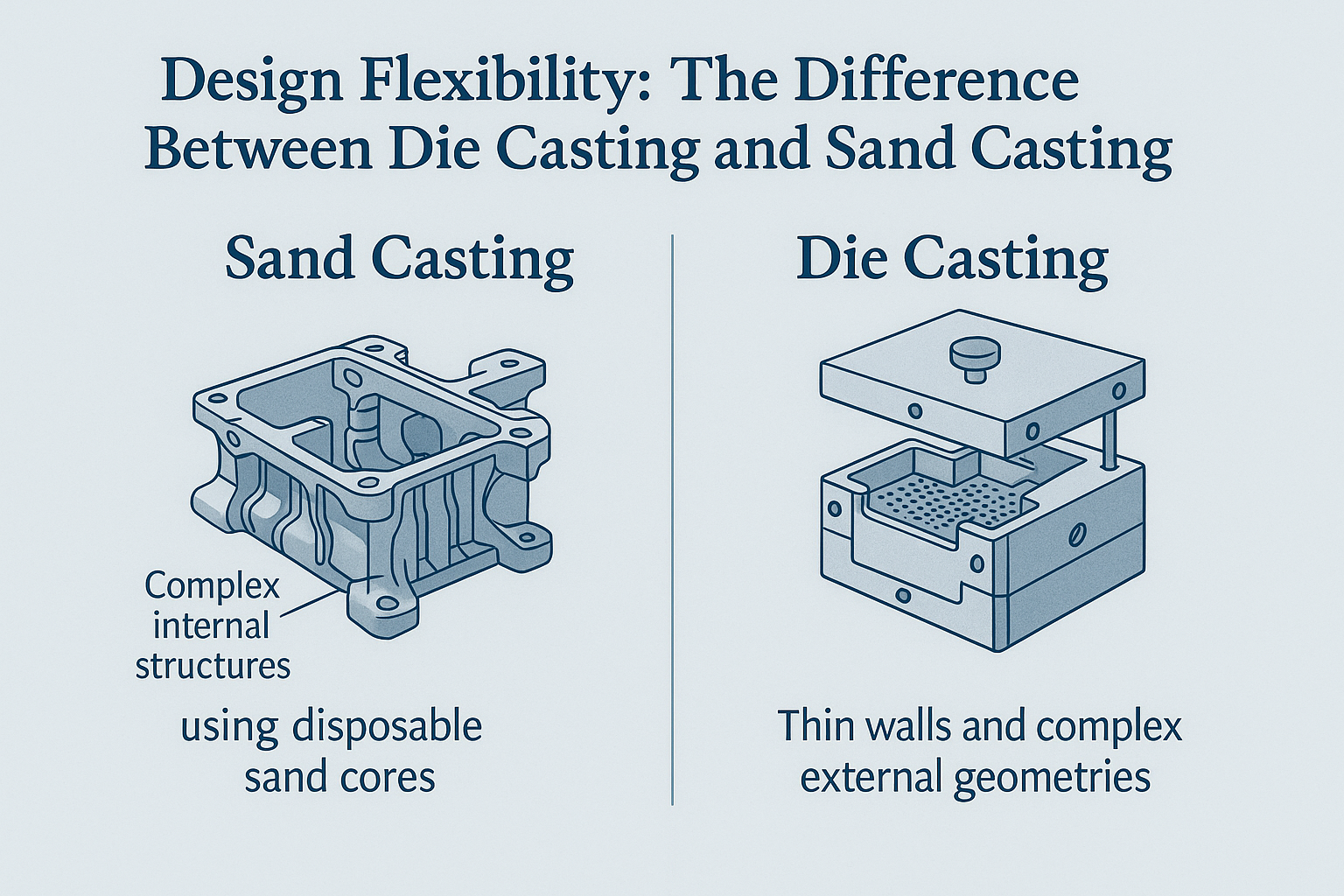

- Design Flexibility: The Difference Between Die Casting and Sand Casting

- Alloy Properties: A380 vs. A356 Aluminum

- Sustainability and Environmental Impact

- Real-World Applications: A Casting Methods Comparison

- Which Casting Method Should You Choose in 2025?

- The Hybrid Approach: Prototyping and Scaling

- Aluminum Die Casting Services

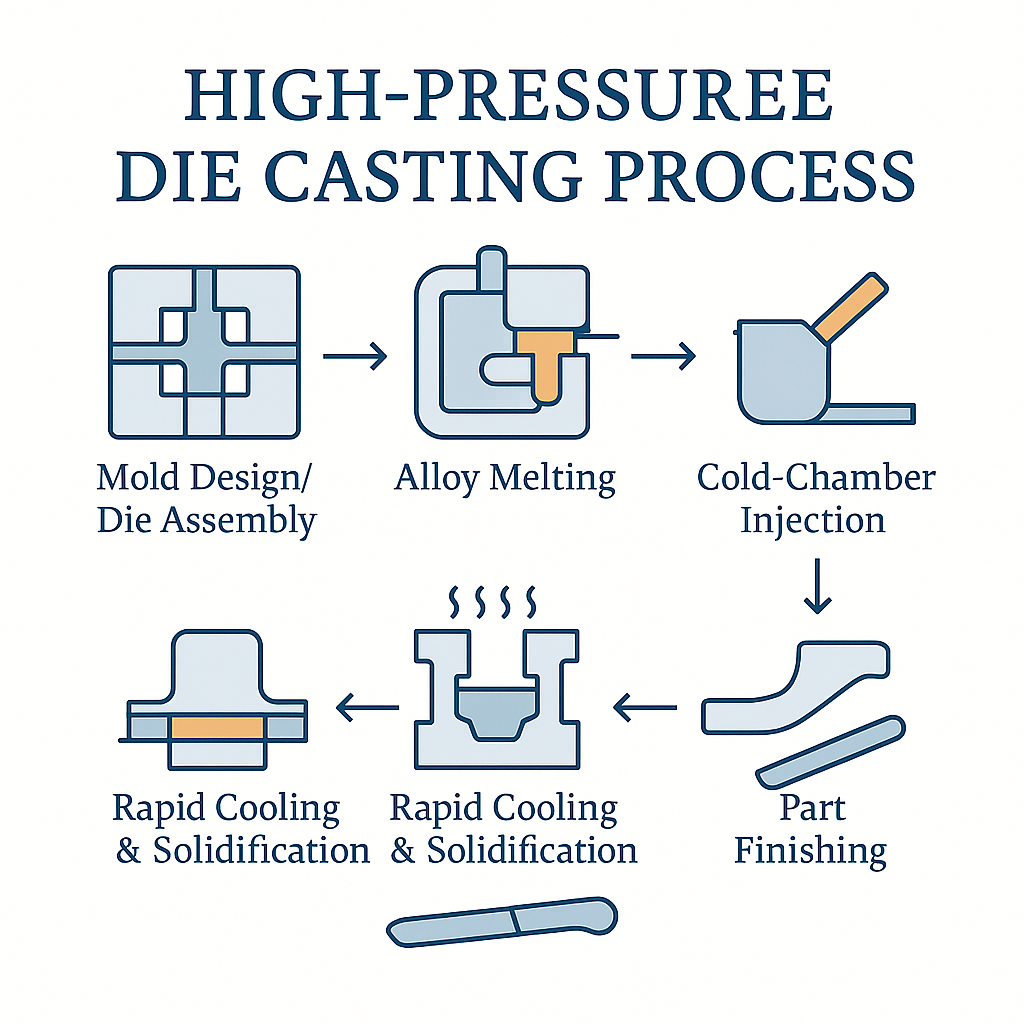

What is Die Casting? A High-Pressure Approach

Die Casting is a high-tech, high-efficiency manufacturing process. Its core principle is to inject molten non-ferrous metals (like aluminum, zinc, and magnesium) under high pressure into a precision-engineered steel mold, known as a “die.” This process is similar to plastic injection molding but is specifically designed for the high temperatures and pressures of metals.

Thanks to its extremely high degree of automation and production speed, die casting can mass-produce parts with complex geometries, thin walls, and smooth surfaces in a very cost-effective manner. This makes it a cornerstone of industries like automotive, electronics, and telecommunications. For example, the smartphone case in your hand, an automotive transmission housing, or a complex heat sink were likely made through die casting. Common die-cast alloys include A380 和 ADC12.

What is Sand Casting? A Versatile and Cost-Effective Method

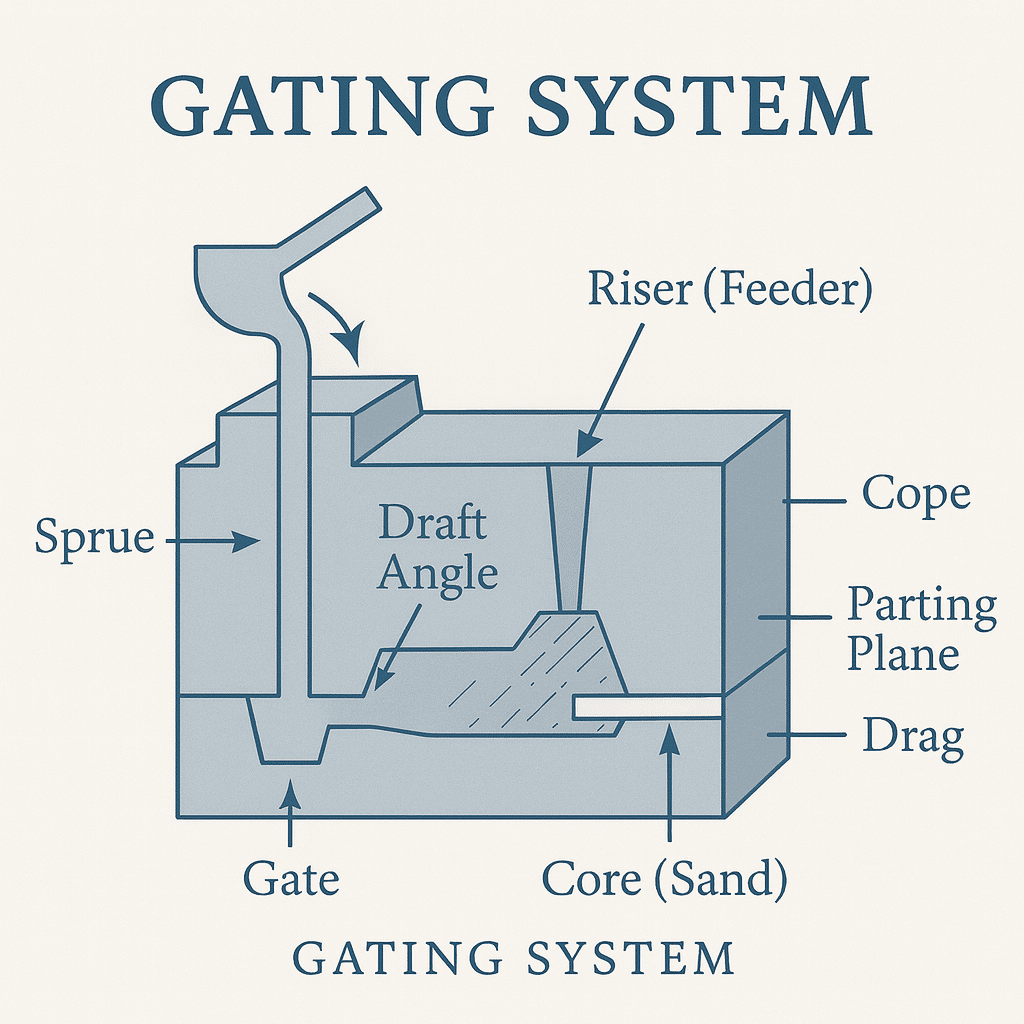

砂型铸造 is an ancient and extremely flexible casting method. As the name suggests, it uses specially treated sand as a single-use mold material. A new sand mold must be created for every part produced.

The process begins with a “pattern,” a physical replica of the final part. The pattern is placed in a molding box (a flask), packed tightly with sand, and then removed, leaving a cavity identical to the part’s shape. Molten metal—which can be ferrous metals like iron and steel or non-ferrous metals like aluminum and copper—is poured into this sand cavity. After it cools and solidifies, the sand mold is broken away to retrieve the casting.

The main advantages of sand casting are its extremely low tooling costs and unparalleled flexibility, allowing it to produce parts ranging in size from a few grams to several tons. This makes it an ideal choice for machinery, heavy equipment manufacturing, and prototype development. Common sand-cast alloys include A356 和 319.

Die Casting vs Sand Casting: Head-to-Head Comparison (7 Key Differences)

To help you quickly understand the core differences between these two processes, we’ve prepared the following intuitive comparison table. This table will serve as an important reference for your decision-making.

| Feature | Die Casting | 砂型铸造 |

| 1. Tooling Cost | 非常高 | 非常低 |

| 2. Production Speed | Extremely Fast (~30-90 sec/cycle) | Slow (Hours per mold) |

| 3. Dimensional Tolerance | Precise (±0.1 mm) | Looser |

| 4. Surface Finish | Smooth (Ra 1–2.5 µm) | Rough |

| 5. Minimum Wall Thickness | Thin walls achievable | Thicker walls required |

| 6. Material Compatibility | Non-ferrous only (Al, Zn, Mg) | Nearly all castable metals |

| 7. Volume Suitability | High-volume production | Low- to mid-volume, prototyping |

Cost Comparison: Die Casting Cost vs Sand Casting Cost

In terms of cost, the economic models of these two processes are complete opposites. Your choice will depend on your upfront budget and the long-term return on investment (ROI).

- Die Casting: Involves a huge initial tooling investment, but once in production, the per-part cost is extremely low. Thanks to high automation and rapid cycle times, it offers unparalleled economic benefits for high-volume production.

- Sand Casting: The initial tooling (pattern) cost is very low, but because a new mold must be made for each part and more subsequent machining is required, its per-part cost is relatively high.

A Case Study: Consider an aluminum part. Using sand casting, the tooling cost is $1,500, and the per-part cost (including machining) is $32. With die casting, the tooling cost is a steep $22,000, but the per-part cost is only $16.20.

- For a run of 1,000 pieces, the total cost of sand casting is lower.

- "(《世界人权宣言》) break-even point is at approximately 1,300 pieces.

- When production reaches 10,000 pieces, choosing die casting will save nearly $140,000 compared to sand casting.

This example clearly shows that production volume is the core economic factor in deciding which process to choose.

Precision and Surface Finish: A Clear Winner

Die casting is far superior in terms of precision and surface finish. By using a precision-machined, hardened steel die, die-cast parts can achieve dimensional tolerances within ±0.1 mm and a very smooth surface (roughness Ra value of 1-2.5 micrometers). This makes die-cast parts “near-net-shape,” requiring little to no subsequent machining.

In contrast, sand castings have a rougher surface and looser dimensional tolerances. This is due to the texture of the sand itself and minor deformations of the mold during pouring. Therefore, sand-cast parts often require additional machining steps to meet final design specifications.

Production Speed and Volume Suitability

Production speed is another major advantage of 压铸. A complete die-casting cycle—from closing the mold to ejecting the part—typically takes only 30 to 90 seconds. This incredible speed makes it perfect for automated production lines and mass production of millions of parts annually.

Sand casting is a relatively slow process. Creating, assembling, pouring, and cooling each sand mold takes several hours. This makes it better suited for low-volume production, custom parts, or large components where a fast per-part cycle time is not the primary concern.

Design Flexibility: The Difference Between Die Casting and Sand Casting

In terms of design freedom, each process has its own strengths, which constitutes a key point in the difference between die casting and sand casting.

- Sand casting has an unparalleled advantage in handling complex internal structures. By using disposable sand cores, it’s easy to create parts with intricate internal channels, such as engine cylinder heads and pump bodies. These cores can be easily broken up and removed after casting.

- Die casting excels at producing parts with thin walls and complex external geometries. The high-pressure injection forces molten metal into every tiny detail of the mold, making it ideal for lightweight electronic enclosures or structurally complex automotive parts. However, creating complex internal cavities with die casting requires expensive and complicated mold slides.

Alloy Properties: A380 vs. A356 Aluminum

The choice of material is closely linked to the casting process.

- A380 铝合金 is the workhorse of the die-casting industry. It contains higher levels of silicon and copper, which give it excellent fluidity, making it ideal for rapidly filling molds under high pressure. However, the die-casting process can easily trap tiny gas pores inside the part. The presence of these pores means that A380 die castings typically cannot be heat-treated, as the high temperatures would cause the internal gas to expand, leading to blisters or distortion.

- A356 aluminum alloy is the premier choice for high-performance sand castings. Because the sand casting filling process is gentler, it creates fewer pores and a denser internal structure. This allows A356 castings to undergo a T6 heat treatment, which significantly increases their strength and toughness. Therefore, for structural parts that must withstand high stress (like in aerospace and high-performance automotive applications), A356 is the superior choice.

Sustainability and Environmental Impact

From a sustainability perspective, both processes are striving to become more environmentally friendly.

- Recycling: Both processes make extensive use of recycled aluminum, which greatly reduces energy consumption and carbon footprint. Excess metal trimmings from die casting are almost 100% recycled and remelted.

- Molds and Sand: A die-casting mold can be reused hundreds of thousands of times, representing excellent material efficiency. Modern sand casting foundries use advanced sand reclamation systems to process used sand for reuse in new molds, significantly reducing waste.

Real-World Applications: A Casting Methods Comparison

Let’s understand this casting methods comparison through some real-world examples.

- Automotive Transmission Housing (Die Casting): This part is needed in huge quantities, has a complex shape, and requires precise dimensions and pressure tightness. Die casting is the only process that can meet all these requirements cost-effectively.

- Engine Cylinder Head (Sand Casting): The cylinder head has an extremely complex network of internal cooling jackets and intake/exhaust ports. This intricate internal structure can only be achieved using sand cores in a sand casting process. Even for high volumes, technical feasibility dictates the choice of sand casting.

- Heavy Machinery Bracket (Sand Casting): These parts are often very large, heavy, and produced in low volumes. Sand casting is the ideal choice for manufacturing such large, low-volume components.

To learn more about industry standards in casting, visit the American Foundry Society.

Which Casting Method Should You Choose in 2025?

Still undecided? Make your final decision based on the following points:

Choose sand casting if your project involves:

- Low volume (under 5,000 pieces) or is a prototype.

- Very large or heavy parts.

- The need for complex internal channels.

- A limited budget that cannot accommodate high tooling costs.

- The use of iron, steel, or other specialty alloys.

Choose die casting if your project involves:

- Very high volume (tens of thousands to millions of pieces).

- The need for very tight dimensional tolerances and a smooth surface.

- Parts with thin walls or complex external details.

- A desire to minimize subsequent machining.

- The pursuit of the lowest per-part cost in the long run.

The Hybrid Approach: Prototyping and Scaling

In modern product development, the smartest strategy is often to combine both methods.

Many companies follow a “sand-to-die” pathway. They first use 砂型铸造 to quickly and inexpensively create prototypes for testing and design validation. Once the design is finalized and the product is ready for mass production, they invest in expensive 压铸 tooling to achieve efficient, low-cost manufacturing. This hybrid approach minimizes development risk and optimizes costs over the entire product lifecycle.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.