快速原型和按需制造,适用于

Smart Home Appliances Industry

In a market fueled by cutting-edge trends, our team delivers rapid, precision die-cast solutions to keep your electronics ahead of the curve.

通过 ISO 9001:2015 认证

即时定价和 DFM

提供精加工、连接和装配

行业专家提供设计和制造指导

CastMold Precision Automotive

压铸解决方案

CastMold 提供专为电信应用设计的高质量铝压铸部件。我们的产品符合严格的行业标准,可在苛刻的环境中保证耐用性和性能。这些精密铸造解决方案专为电信外壳、天线组件和网络设备而设计,可为关键通信系统提供可靠的保护。

制造过程可确保质量和尺寸精度的一致性,从而实现与电信设备的无缝集成。我们的元件在电信安装中常见的温度变化、湿度暴露和机械应力条件下都能保持稳定的性能。

耐腐蚀性

- 铝的天然氧化层可提供长期保护,防止环境恶化。

轻质强度

- 高强度重量比实现了耐用而便携的电信设备设计。

EMI 屏蔽

- 为敏感的通信电子设备提供有效的电磁干扰保护。

精密制造

- 严格的公差确保了复杂电信组件的适当配合和功能。

环境耐久性

- 可承受户外条件,包括紫外线照射、潮湿和极端温度。

CastMold 提供从原型设计到生产的服务

1

原型设计

原型设计是汽车产品开发的初始阶段。 在这一阶段,您需要验证设计,进行必要的修改,并为部件选择最佳材料。

- 快速、经济高效的调整 设计和材料

- 高精度原型 具有复杂的几何形状

- 真实生产模型 反映最后的部分

2

工程验证和测试

这一阶段的重点是通过材料选择和表面处理分析来验证零件的功能性、美观性和性能。在 CastMold,我们根据您的设计规格提供广泛的材料库和表面处理解决方案。这一阶段的原型不仅能满足功能要求,还能达到市场要求的美观度,非常适合实际测试。

- 全天候工程支持 实现无缝开发

- 高精度制造 关键部件

- 量身定制的材料解决方案 优化定制设计的性能

3

设计验证和测试

这一阶段的重点是通过材料选择和表面处理分析来验证零件的功能性、美观性和性能。在 CastMold,我们根据您的设计规格提供广泛的材料库和表面处理解决方案。这一阶段的原型不仅能满足功能要求,还能达到市场要求的美观度,非常适合实际测试。

- 经久耐用的优质表面处理 美观大方,性能卓越

- 全面验证 外观、合身性和功能

- 生产级原型 消费者反馈和市场评估

4

生产验证和测试

这一关键阶段是连接原型设计和全面制造的桥梁,确保无缝过渡到批量生产。在CastMold,我们利用严格的质量控制和工业级制造来完善您的设计,以实现批量生产。我们的团队与您紧密合作,完善模具、优化工艺、确定规格--提供符合精确要求的可生产零件。

- 制造工艺验证 质量稳定

- 小批量生产工具 可灵活提升

- 快速交付 最终用途组件

- 综合评估 生产部件的性能和可靠性

5

大规模生产

这一阶段标志着从验证到全面制造的过渡,实现最终使用部件的大批量生产。在 CastMold,我们将先进的机械设备、熟练的工程技术和严格的质量协议结合起来,确保在不影响精度的情况下快速周转,满足最苛刻的规格要求。

- 严格的质量控制 - 每个部件都经过严格检查,以确保一致性和可靠性。

- 优质定制制造 - 为材料、表面处理和功能要求量身定制解决方案。

- 二次加工 - 附加处理(如阳极氧化、电镀、抛光),以提高耐用性和美观度。

- 高精度 - 先进的数控加工和成型技术可确保完美的尺寸精度。

我们的压铸能力

CastMold 公司专门为客户量身定制高精度压铸解决方案。我们利用最先进的冷室和热室压铸技术,实现大批量生产,并具有卓越的尺寸精度和表面光洁度。我们的专业技术涵盖铝合金和锌合金,可确保轻质耐用的零件达到最佳性能。

我们配备自动化系统和实时质量监控,在保持严格公差(±0.05 毫米)的同时,实现了快速的生产周期。从原型设计到全面生产,我们的端到端服务包括模具设计、后处理(数控加工、电镀、涂层)和严格检测(X 射线、坐标测量机),以满足航空航天、电信和工业标准的要求。

应用

Precision Lighting Components

From custom-designed lighting housings to high-performance optical and thermal management systems, CastMold Lighting provides precision aluminum die-cast components that meet the demands of modern lighting solutions. As a specialized die-casting manufacturer, we offer the following tailored solutions:

LED heat sinks & housings

Outdoor fixture enclosures (IP66/IP68 rated)

Optical reflector assemblies

Architectural mounting brackets

Smart lighting sensor casings

Decorative luminaire frames

Weatherproof junction boxes

EV Charging Port

Lightweight die-cast charging interface

Aluminum alloy ensures thermal management for fast charging, corrosion-resistant & automotive-grade compliance

Spotlight Lightbox

Seamless die-cast outdoor lightbox

IP65-rated aluminum housing with lightweight durability reduces installation complexity

Phone Holder

Multi-purpose die-cast holder

Reinforced aluminum frame with anti-slip silicone, resistant to deformation & abrasion

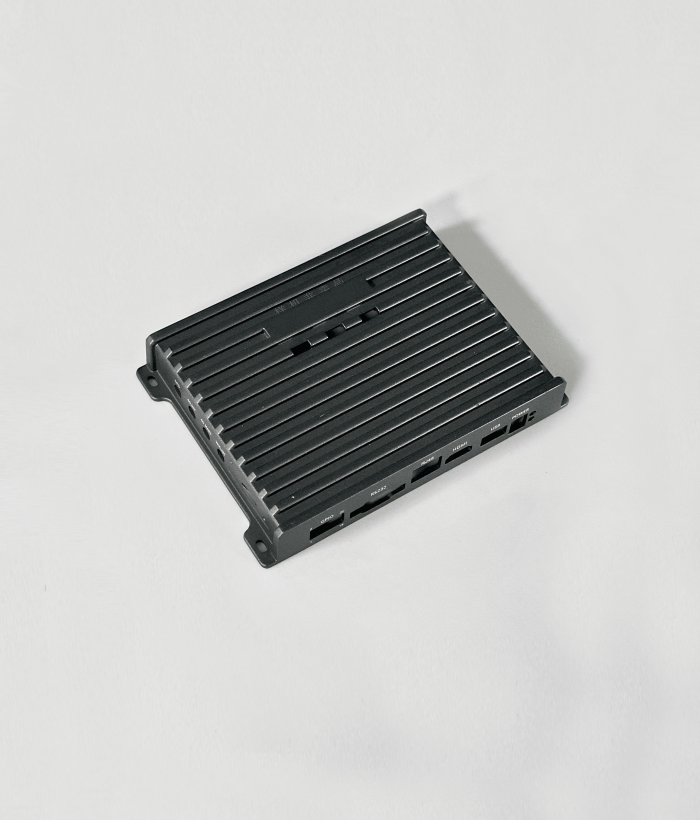

Communication Housing

5G base station die-cast enclosure

EMI-shielded aluminum with heat dissipation, precision tolerance for critical deployments

Industrial Coupling

Extreme-condition die-cast couplings

High-strength alloy withstands -40℃~200℃, low porosity enhances fatigue resistance

Coffee Machine Housing

Food-safe die-cast body

Lead-free aluminum withstands high heat, compliant with commercial hygiene protocols

常见问题

Die casting is a metal casting process where molten metal is forced under high pressure into a reusable steel mold cavity6. The mold, composed of two hardened dies, operates similarly to an injection mold, enabling high-volume production of small to medium-sized parts with excellent surface finish and dimensional consistency6. Key steps include melting the metal (commonly aluminum, zinc, or magnesium alloys64), injecting it into the die under high pressure, and cooling to form the final part6.

This process is widely used in automotive manufacturing for lightweight, complex components like engine blocks and structural frames41. For example, Tesla employs 6,000-ton gigacasting machines for front and rear underbody parts1, while AITO M9 uses a 9,000-ton press for rear sections1. Advantages include cost-effectiveness (due to reusable dies), rapid production cycles, and high structural integrity46.

1. Wall Thickness

Maintain uniformity (2.5–4 mm for aluminum alloys), avoid thick sections (>6 mm) to prevent gas porosity; use ribs/gussets instead of localized thickening, and ensure gradual transitions to reduce stress.

2. Draft Angle

Minimum 0.25°–1.5° (1°–3° for deep cavities or textured surfaces); align draft direction with mold opening to avoid undercuts.

3. Fillets

Internal radii ≥0.5 mm (recommended: 1/2 to full wall thickness) to enhance strength and fill; round external edges for easier mold maintenance.

4. Gating System

Place gates near thick sections for laminar flow to minimize air entrapment; tapered runners and small gates require high pressure but simplify trimming.

5. Venting

Add 0.1–0.15 mm deep vent slots along the parting line; critical components use vacuum-assisted systems with dual vents to reduce porosity.

6. Geometric Simplification

Eliminate undercuts, optimize parting lines for minimal complexity, and adopt symmetry to reduce thermal distortion and improve mold stability.

The tolerances for die casting vary depending on the process and part dimensions. For pressure diecasting, the flatness tolerance is typically 0.2 mm for dimensions up to 75 mm, with an additional 0.075 mm added per 25 mm increase in size4. These values reflect standard production practices optimized for cost-effectiveness. Higher precision may require specialized processes or additional post-casting machining. For example, surface roughness in high-pressure die casting can achieve Ra 1.6–6.3 μm under optimal conditions1, though dimensional tolerances remain primarily governed by the casting size and material flow characteristics. Designers should specify tighter tolerances only where functionally necessary, as achieving them often increases production complexity.

Our design team utilizes specialized software for product development and mold flow analysis, ensuring designs meet production requirements. Through pre-production simulations, we optimize processes to reduce trial runs and improve yield.

We are well-versed in PPAP processes and can prepare complete Production Part Approval documentation, guiding clients through the review procedures.

Our ISO 9001:2015 certified quality management system ensures full-process monitoring from raw materials to finished products, including first-article inspection, in-process checks, and final inspection.

We implement annual improvement plans, regularly optimizing processes and efficiency through customer feedback and production data analysis.

We offer flexible lead times of 2-10 weeks, tailored to design complexity and client requirements. Through parallel design confirmation and modular manufacturing solutions, standard projects can be delivered in as fast as 2 weeks, with complex projects completed within 10 weeks maximum.