快速原型和按需制造,适用于

Lighting Industry

In an industry illuminated by energy-efficient innovation, we provide high-performance die-cast components that empower luminaire designs to shine brighter, last longer, and outperform expectations.

通过 ISO 9001:2015 认证

即时定价和 DFM

提供精加工、连接和装配

行业专家提供设计和制造指导

CastMold Precision Lighting

压铸解决方案

CastMold specializes in premium aluminum die-cast components optimized for lighting industry applications. Our solutions are engineered to meet rigorous performance standards for both commercial and industrial lighting systems. Designed for LED housing, heat sinks, streetlight enclosures, and decorative fixture frames, our precision-cast components ensure reliable operation and extended service life in diverse lighting environments.

The die-casting process guarantees exceptional consistency and structural integrity, enabling seamless integration with optical modules, electrical circuits, and mounting systems. Our components deliver stable performance under continuous thermal cycling, vibration, and harsh weather conditions typical of outdoor and industrial lighting installations.

Thermal Management Excellence

High thermal conductivity rapidly dissipates LED heat, preventing lumen degradationLightweight Structural Durability

High strength-to-weight ratio enables slim, complex designs while resisting deformation.Corrosion & Weather Resistance

Anodized surfaces and IP65/68 enclosures withstand UV, moisture, and chemicals.EMI/RFI Shielding

Effective electromagnetic protection for smart lighting circuitry.

CastMold 提供从原型设计到生产的服务

1

原型设计

原型设计是汽车产品开发的初始阶段。 在这一阶段,您需要验证设计,进行必要的修改,并为部件选择最佳材料。

- 快速、经济高效的调整 设计和材料

- 高精度原型 具有复杂的几何形状

- 真实生产模型 反映最后的部分

2

工程验证和测试

这一阶段的重点是通过材料选择和表面处理分析来验证零件的功能性、美观性和性能。在 CastMold,我们根据您的设计规格提供广泛的材料库和表面处理解决方案。这一阶段的原型不仅能满足功能要求,还能达到市场要求的美观度,非常适合实际测试。

- 全天候工程支持 实现无缝开发

- 高精度制造 关键部件

- 量身定制的材料解决方案 优化定制设计的性能

3

设计验证和测试

这一阶段的重点是通过材料选择和表面处理分析来验证零件的功能性、美观性和性能。在 CastMold,我们根据您的设计规格提供广泛的材料库和表面处理解决方案。这一阶段的原型不仅能满足功能要求,还能达到市场要求的美观度,非常适合实际测试。

- 经久耐用的优质表面处理 美观大方,性能卓越

- 全面验证 外观、合身性和功能

- 生产级原型 消费者反馈和市场评估

4

生产验证和测试

这一关键阶段是连接原型设计和全面制造的桥梁,确保无缝过渡到批量生产。在CastMold,我们利用严格的质量控制和工业级制造来完善您的设计,以实现批量生产。我们的团队与您紧密合作,完善模具、优化工艺、确定规格--提供符合精确要求的可生产零件。

- 制造工艺验证 质量稳定

- 小批量生产工具 可灵活提升

- 快速交付 最终用途组件

- 综合评估 生产部件的性能和可靠性

5

大规模生产

这一阶段标志着从验证到全面制造的过渡,实现最终使用部件的大批量生产。在 CastMold,我们将先进的机械设备、熟练的工程技术和严格的质量协议结合起来,确保在不影响精度的情况下快速周转,满足最苛刻的规格要求。

- 严格的质量控制 - 每个部件都经过严格检查,以确保一致性和可靠性。

- 优质定制制造 - 为材料、表面处理和功能要求量身定制解决方案。

- 二次加工 - 附加处理(如阳极氧化、电镀、抛光),以提高耐用性和美观度。

- 高精度 - 先进的数控加工和成型技术可确保完美的尺寸精度。

我们的压铸能力

CastMold 公司专门为客户量身定制高精度压铸解决方案。我们利用最先进的冷室和热室压铸技术,实现大批量生产,并具有卓越的尺寸精度和表面光洁度。我们的专业技术涵盖铝合金和锌合金,可确保轻质耐用的零件达到最佳性能。

我们配备自动化系统和实时质量监控,在保持严格公差(±0.05 毫米)的同时,实现了快速的生产周期。从原型设计到全面生产,我们的端到端服务包括模具设计、后处理(数控加工、电镀、涂层)和严格检测(X 射线、坐标测量机),以满足航空航天、电信和工业标准的要求。

应用

Precision Lighting Components

From custom-designed lighting housings to high-performance optical and thermal management systems, CastMold Lighting provides precision aluminum die-cast components that meet the demands of modern lighting solutions. As a specialized die-casting manufacturer, we offer the following tailored solutions:

LED heat sinks & housings

Outdoor fixture enclosures (IP66/IP68 rated)

Optical reflector assemblies

Architectural mounting brackets

Smart lighting sensor casings

Decorative luminaire frames

Weatherproof junction boxes

Lampshade

Precision die-cast aluminum alloy housing and heat sinks for LED applications, delivering superior thermal management and structural durability through advanced casting technology.

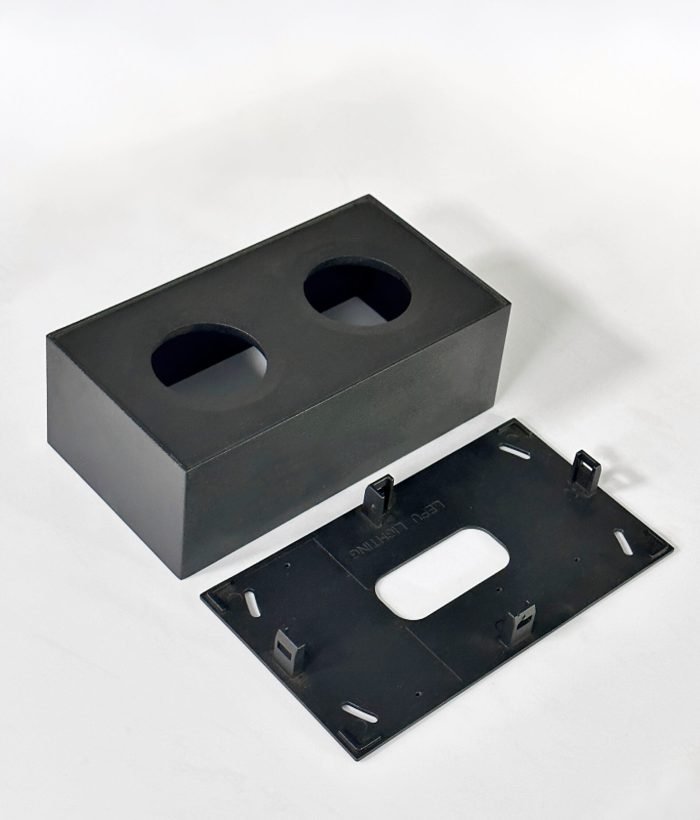

Spotlight Lightbox

Seamless die-cast outdoor lightbox

IP65-rated aluminum housing with lightweight durability reduces installation complexity

Spotlight Heatsinks

Die-cast aluminum alloy spotlight heatsinks engineered for efficient thermal dissipation and robust performance, leveraging advanced aluminum die-casting technology for precision and durability

High-power lighting heatsinks

High-power lighting heatsinks engineered with die-cast aluminum alloy technology ensure superior thermal dissipation and durability for demanding applications.

Integrated street light housing heatsink

Die-cast aluminum alloy street light heatsinks with IP68-rated waterproof and corrosion-resistant properties ensure efficient heat dissipation and durability via advanced die-cast technology.

常见问题

Aluminum die-castings are ideal for lighting housings and heat dissipation components due to their lightweight, high thermal conductivity, and strong corrosion resistance. For example, LED fixtures demand superior heat dissipation, and aluminum’s high thermal conductivity (e.g., pure aluminum die-castings with a thermal conductivity of 192 W/m·K) significantly extends lamp lifespan. Additionally, its high-precision forming capability meets complex lighting design requirements.

- Lightweight: Reduces fixture weight for easier installation and transportation.

- Efficient heat dissipation: Enhances thermal management for LED fixtures.

- Corrosion resistance: Suitable for outdoor and harsh environments.

- Machinability: Enables intricate designs (e.g., textures and thin-walled structures) via molds.

- Cost-effectiveness: Mass production lowers per-unit costs.

Common Surface Treatments:

- Anodization: Enhances corrosion resistance and allows color customization.

- Powder Coating: Improves mechanical strength and weather resistance for outdoor fixtures.

- Sandblasting: Increases surface roughness for better adhesion.

- Eco-Friendly Chemical Polishing: Reduces pollution while improving surface finish.

- Porosity Defects: High-speed casting may cause internal voids, affecting anodization quality.

- High Mold Costs: Complex molds increase barriers for small-batch production.

- Process Compatibility: Traditional high-silicon aluminum alloys limit surface treatment options.

Sustainability Advantages:

- Recyclability: Aluminum has a recycling rate exceeding 90%, minimizing waste.

- Energy-Efficient Production: Mass production reduces energy consumption.

- Long Lifespan: Corrosion and thermal resistance extend fixture longevity, reducing replacement frequency.

Material Selection:

- ADC12: High fluidity, suitable for thin-walled components.

- YL112: Used for automotive and lighting structural parts; requires surface treatment to enhance corrosion resistance.

- Pure Aluminum: CastMold’s proprietary formula, offering high thermal conductivity and compatibility with anodization.

- High Precision and Miniaturization: Meets the demand for compact components in smart lighting.

- Green Processes: Nitrate-free polishing and low-energy surface treatments.

- Smart Production: AI-driven mold design and real-time process optimization.

Quality Control Measures:

- Mold Inspection: Regular maintenance to prevent burrs and dimensional errors.

- Non-Destructive Testing (NDT): X-ray or ultrasonic inspection to check internal porosity.

- Surface Testing: Salt spray tests to detect corrosion resistance; reflectivity checks to assess optical performance.

The heat dissipation of LEDs directly affects their luminous efficiency and lifespan. The high thermal conductivity of aluminum enables rapid heat dissipation, preventing luminous flux decay. For example, compared to traditional materials, pure aluminum heat sinks can reduce temperatures by over 20%.