Yetenekler

Zinc Die Casting Services

High-precision zinc die casting (±0.05mm) with electroplating, sandblasting and painting. Prototyping to mass production. Salt spray certified for automotive and electronics

ISO 9001:2015 Sertifikalı

Samples as fast as 10-15 days

Expert DFM & Engineering Support

100% Dimensional Inspection Guarantee

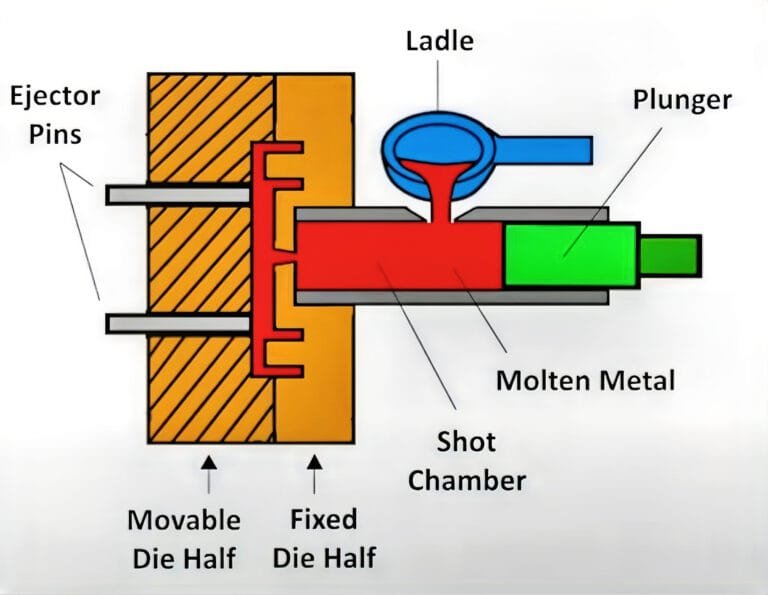

What is Zinc Die Casting?

Zinc die casting operates through a thermally integrated hot-chamber system, injecting molten ZAMAK alloys (solidus 380°C) into lubricant-coated steel dies under 65-95MPa pressure. The material’s intrinsic properties – including 1.5-2.5% linear shrinkage and 325-425MPa tensile strength – enable 0.1-0.4mm wall thickness precision with ±0.025mm dimensional tolerance. Process economics derive from 300°C lower melt temperatures versus aluminum, yielding 2.8X extended die service life (1M+ cycles) and 40% lower per-unit costs for high-volume automotive fasteners and IoT device housings requiring <50μm surface roughness.

At CastMold, we optimize zinc die casting with 3D-validated DFM guidance, 7-day rapid prototyping . Our integrated process accelerates product development cycles by 30% while maintaining ±0.05mm tolerances, supporting seamless transition from prototypes to 50,000+ unit production runs.

Steps of the Zinc Die Casting Process

The zinc hot-chamber die casting process comprises four critical control phases with quantified parameters:

Die Preparation

Molten Injection

Solidification Control

Finishing & Inspection

ONE-STOP DIE CASTING SOLUTION

We go beyond traditional die casting. Our end-to-end service spans design optimization, rapid prototyping, high-volume production, ve precision finishing. From concept to final part, we streamline your workflow with expert collaboration, rigorous quality control, and fast turnaround—all in a single trusted partnership.

- Design Optimization: Leverage simulation-driven DFM (Design for Manufacturing) analysis to enhance part geometry, minimize material waste, and ensure cost-efficient production feasibility.

- Rapid Prototyping: Deliver functional prototypes in 5-7 days using CNC machining or 3D-printed patterns for design validation and tolerance verification.

- High-Volume Production: Scale seamlessly with automated high-pressure die casting (HPDC) systems and real-time process monitoring for consistent output at 10,000+ unit batches.

- Precision Finishing: Apply tailored surface treatments (anodizing, shot blasting) and CNC machining to achieve Ra 0.8μm surface roughness or tighter per ISO 1302 standards.

One Stop Die Casting Service

Die Casting Prototyping

We offer complete prototyping services from 3D printing to functional die-cast samples, significantly reducing product validation cycles.

- Multi-material capabilities (engineering plastics and metals) combined with rapid CNC machining for greater design flexibility

- Hybrid prototyping workflow shortens lead times by 25% while ensuring geometric compliance with mass production requirements

Die Casting Tooling

Our high-precision mold design, integrated with CAE-optimized gating systems, effectively reduces porosity and ensures stable filling performance.

- Modular mold design enables multi-cavity production and insert molding for complex part requirements

- Proprietary surface treatments and tool maintenance programs extend mold lifespan by 40%

Çinko Basınçlı Döküm

Vacuum-assisted high-pressure die casting technology enables ultra-thin aluminum castings (minimum 0.6mm wall thickness) for lightweight, high-strength structures.

- Process controls for specific alloys (A380/ADC12) ensure mechanical properties meet ASTM/ISO standards

- Combined T6 heat treatment and X-ray inspection to meet automotive industry demands for structural integrity

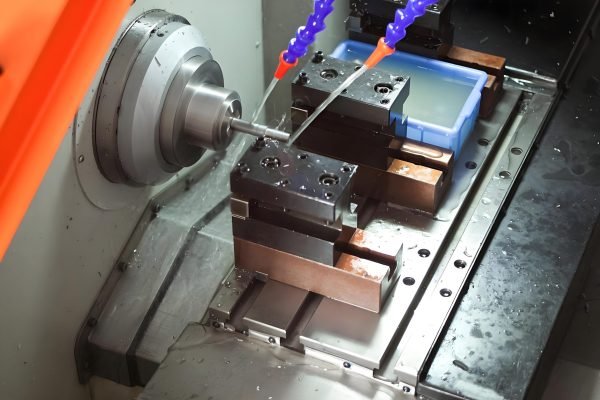

Secondary CNC Machining

We deliver ±0.01mm ultra-precision CNC finishing for critical sealing surfaces and mating interfaces.

- 5-axis simultaneous machining efficiently handles deep-cavity parts and complex undercut geometries

- In-process CMM inspection guarantees compliance with GD&T standards for every production batch

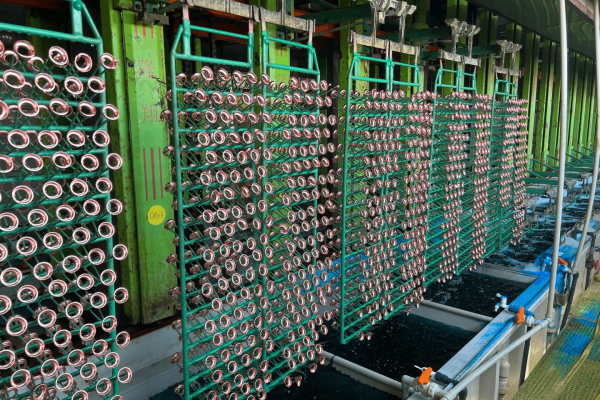

Die Casting Surface Finishing

Achieve Ra0.2μm mirror finishes via multi-stage polishing or opt for fingerprint-resistant textured coatings through anodization.

- Custom PVD coatings (e.g., TiN/CrN) provide wear resistance up to 1,200HV in harsh environments

- RoHS-compliant electrophoretic coating delivers over 500-hour salt spray corrosion resistance

CastMold Die Casting Capabilities

Excellent Die Casting Quality

Through strict quality control measures and precise rejection criteria, our production system guarantees dimensional accuracy and aesthetic integrity in every casting. By implementing quantifiable surface finish standards, we ensure quality alignment between design specifications and manufactured components.

- Dimensional metrology (CMM with ±2μm repeatability)

- Material verification (XRF spectrometry compliant with ASTM E1621)

- Structural integrity testing (X-ray/CT scanning for porosity ≤0.2%)

- Environmental compliance (RoHS/REACH certification)

- Corrosion resistance validation (1000hrs salt spray testing per ASTM B117)

Die Cast Parts Engineering Support

CastMold’s seasoned engineering team partners with clients from concept development to mass production, delivering design-driven manufacturing excellence.

DESIGN-TO-PRODUCTION ENGINEERING SOLUTIONS

Our engineers leverage advanced CAE simulations and 20+ years of die-casting expertise to:

- Optimize product/tooling designs for manufacturability using CAD/CAM integration

- Conduct mold flow analysis to prevent defects (porosity, warping) during filling/solidification

- Streamline prototyping-to-production transitions through virtual verification systems

- Implement value engineering strategies for cost-efficient material usage and process optimization

- Proficiency in Pro/Engineer and parametric modeling ensures seamless translation of digital designs into high-performance tooling and cast components.

Basınçlı Döküm

Products Gallery

From compact high-tolerance components (±0.05mm) to heavy-duty structural assemblies, we engineer defect-free die-cast parts in aluminum/zine alloys for automotive, robotics, and consumer electronics.

EV Charging Port

Lightweight die-cast charging interface

Aluminum alloy ensures thermal management for fast charging, corrosion-resistant & automotive-grade compliance

Spotlight Lightbox

Seamless die-cast outdoor lightbox

IP65-rated aluminum housing with lightweight durability reduces installation complexity

Telefon Tutucu

Çok amaçlı döküm tutucu

Kaymayı önleyici silikon ile güçlendirilmiş alüminyum çerçeve, deformasyona ve aşınmaya karşı dayanıklı

Communication Housing

5G base station die-cast enclosure

EMI-shielded aluminum with heat dissipation, precision tolerance for critical deployments

Industrial Coupling

Extreme-condition die-cast couplings

High-strength alloy withstands -40℃~200℃, low porosity enhances fatigue resistance

Coffee Machine Housing

Food-safe die-cast body

Lead-free aluminum withstands high heat, compliant with commercial hygiene protocols

Types of Die Casting Processes

CastMold delivers tailored die casting solutions through Hot Chamber and Cold Chamber Die Casting technologies, optimized for diverse materials (aluminum, zinc) and production scales. Our expertise ensures seamless adaptation to your project’s structural complexity, volume demands, and cost targets.

![热室压铸 {"source_type":"douyin_beauty_me","data":{"capability_key":[],"playId":"","enter_from":"enter_launch","infoStickerId":"","filterId":"","stickerId":"","imageEffectId":"","alias":"f2hooZ9BhRn1JeFSvdYpY/JFx3yKZrG2mLbk5Tk5hfZ8eFDI3TrwADuYO24OGME1/zLp8r2eUSxbCm6BvLN7DJlc1AqH29VE80BIsfPC4D8FuDmgKcVmG/QHZxffvuFCJWEOugqR0Kiq9wXgXdYpF+bSSfvFOk8Oo0FAjS6nEHcFB/WJLT3gZBn1OjLPEwNJbJnOCi0CNDXfQXlk5NnFlPNvbBOaNT1XQxGLbLLSDhIUJJ3RO6CGbEAeXQHrvQf90+gcrSTnF+eCfmbx/Cyl+eP84llY91LYFUkD7epR1zp2Z4YaXolXqkZMQeOK0V3uQk7cIJA8mOniUrYn2NdSEg==","product":"retouch","activityName":"","capability_extra_v2":{},"pictureId":"26D343B4-9EDB-4CE9-AEB3-319AC9698E96","appversion":"11.8.0","os":"ios"}}](https://cast-mold.com/wp-content/uploads/elementor/thumbs/热室压铸-r2uf6rdmdx1nepeikxn9meqgqbzprap4o54utbkq48.jpg)

Hot Chamber Die Casting

Cold Chamber Die Casting

Uygulamaları

Çinko Basınçlı Döküm

- Automotive:Door locks, handles, radiators, engine components, sensor casings.

- Electronics Industry: Electronic device housings, connectors, plugs, shielding cases, brackets.

- Home appliances: Faucets, shower heads, locks, handles, knobs.

- Medical Equipment: Precision medical instrument parts, pump components, device housings.

- Toys and Decorative Items: Fine model toys, decorative accessories, badges, keychains.

Advantages of

Çinko Basınçlı Döküm

- High Precision: Capable of producing complex shapes with very tight tolerances.

- Excellent Surface Finish: Easily supports surface treatments like electroplating, painting, polishing, and electrophoresis.

- Good Strength and Hardness: Zinc alloys offer higher mechanical strength and wear resistance compared to plastics.

- High Production Efficiency: High Production Efficiency

- Cost-Effective: Long mold life helps reduce overall production costs.

Disadvantages of

Çinko Basınçlı Döküm

- Heavier Weight: Zinc alloys have a higher density, making products heavier than those made from aluminum alloys or plastics.

- Limited Corrosion Resistance: Uncoated zinc alloy products may be prone to corrosion, especially in humid conditions.

- Lower Temperature Stability: Zinc alloys can deform or soften at higher temperatures, limiting use in high-temperature applications.

- Relatively Higher Material Cost: Zinc alloys can be more expensive compared to some aluminum alloys and plastics.

- Environmental Impact: Improper disposal or handling of zinc alloys could negatively affect the environment, emphasizing the need for proper recycling and management.

SSS

We primarily use Zamak 2, Zamak 3, Zamak 5 and Zamak 7, offering tensile strength from 190 to 255 MPa, Brinell hardness HB80–HB100, and elongation of 5–10%.

Zinc alloys generally enable lower tooling costs and finer feature detail, with part-unit cost comparable—or even lower—for small to medium runs, while aluminum may be more economical at very high volumes due to material pricing.

We routinely cast down to 0.4 mm wall thickness; standard dimensional tolerance is ±0.1 mm for features under 50 mm and ±0.2% for larger sections.

We support powder coating, electro-plating (nickel, chrome, zinc), painting, anodizing, and polishing—each tailored for adhesion, corrosion resistance, and appearance.

Our MOQ is 500 pcs. We offer tiered pricing: standard rates for 500–2,000 pcs, above 5,000 pcs and custom quotes for larger runs.

From mold design to first samples typically takes 15–20 days; mass production lead time is 20–30 days, depending on order size and finish complexity.

Typical mold cost ranges depending on cavity count and complexity. We can amortize mold cost over the part price or hold the tool for future runs.

We perform CMM, X-ray/CT, hardness, salt spray, 2D vision, and caliper checks. Full inspection reports with data sheets are provided per batch.

Yes. Our alloys and processes fully comply with RoHS, REACH, and other global environmental standards. We also recycle scrap material to minimize waste.

Bare zinc alloy has moderate corrosion resistance; with proper electro-plating or powder coating, parts pass 500 + hours salt spray tests for long-term outdoor use.