Yetenekler

Alüminyum Basınçlı Döküm Hizmetleri

CastMold’s die-casting solutions deliver high-performance, precision-crafted components with superior dimensional consistency and flawless surface finishes. These advanced castings minimize secondary machining requirements and enhance component compatibility, enabling accelerated production cycles and significant cost efficiencies.

ISO 9001:2015 Sertifikalı

Samples as fast as 10-15 days

Expert DFM & Engineering Support

100% Dimensional Inspection Guarantee

What is

Die Casting?

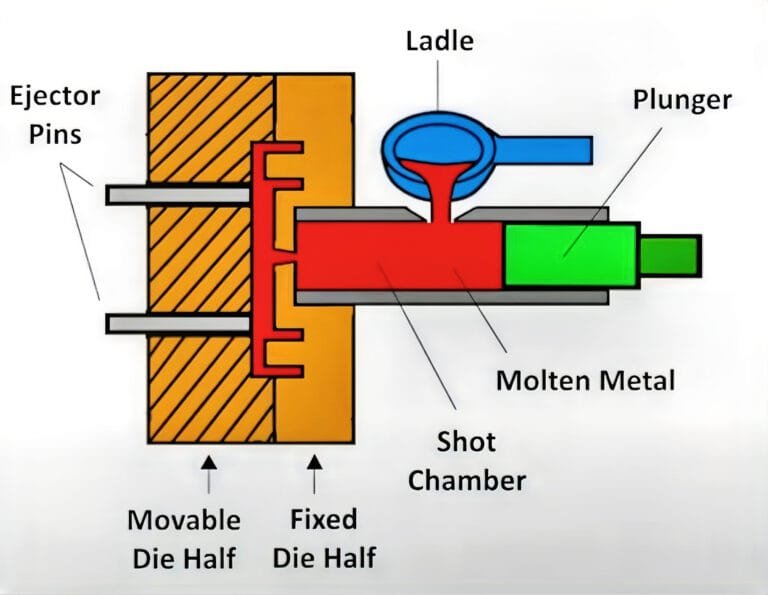

Die casting is a high-efficiency manufacturing process for producing complex, precision metal components at scale. It utilizes precision-engineered molds (dies) to inject molten metals—such as aluminum, zinc, or magnesium alloys—under extreme pressure, enabling rapid solidification that captures intricate geometries with minimal post-processing. Ideal for high-volume production, this method ensures consistent part quality, tight tolerances (±0.1mm), and superior surface finishes while reducing material waste.

At CastMold, we enhance this process with design-for-manufacturability (DFM) guidance, 7-10 day prototype delivery, and 100% dimensional inspection to guarantee your parts meet both functional and aesthetic requirements. Our advanced die casting solutions bridge rapid prototyping to mass production, ensuring cost efficiency and durability for industries ranging from automotive to consumer electronics.

Basınçlı Döküm

Production Process

Die Design & Preheating

Melting & High-Pressure Injection

Solidification & Cooling

Post-Processing & Quality Control

ONE-STOP DIE CASTING SOLUTION

We go beyond traditional die casting. Our end-to-end service spans design optimization, rapid prototyping, high-volume production, ve precision finishing. From concept to final part, we streamline your workflow with expert collaboration, rigorous quality control, and fast turnaround—all in a single trusted partnership.

- Design Optimization: Leverage simulation-driven DFM (Design for Manufacturing) analysis to enhance part geometry, minimize material waste, and ensure cost-efficient production feasibility.

- Rapid Prototyping: Deliver functional prototypes in 5-7 days using CNC machining or 3D-printed patterns for design validation and tolerance verification.

- High-Volume Production: Scale seamlessly with automated high-pressure die casting (HPDC) systems and real-time process monitoring for consistent output at 10,000+ unit batches.

- Precision Finishing: Apply tailored surface treatments (anodizing, shot blasting) and CNC machining to achieve Ra 0.8μm surface roughness or tighter per ISO 1302 standards.

One Stop Die Casting Service

Die Casting Prototyping

We offer complete prototyping services from 3D printing to functional die-cast samples, significantly reducing product validation cycles.

- Multi-material capabilities (engineering plastics and metals) combined with rapid CNC machining for greater design flexibility

- Hybrid prototyping workflow shortens lead times by 25% while ensuring geometric compliance with mass production requirements

Die Casting Tooling

Our high-precision mold design, integrated with CAE-optimized gating systems, effectively reduces porosity and ensures stable filling performance.

- Modular mold design enables multi-cavity production and insert molding for complex part requirements

- Proprietary surface treatments and tool maintenance programs extend mold lifespan by 40%

Alüminyum Basınçlı Döküm

Vacuum-assisted high-pressure die casting technology enables ultra-thin aluminum castings (minimum 0.6mm wall thickness) for lightweight, high-strength structures.

- Process controls for specific alloys (A380/ADC12) ensure mechanical properties meet ASTM/ISO standards

- Combined T6 heat treatment and X-ray inspection to meet automotive industry demands for structural integrity

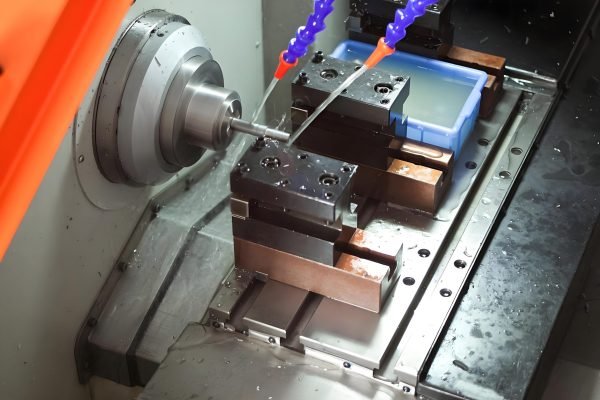

Secondary CNC Machining

We deliver ±0.01mm ultra-precision CNC finishing for critical sealing surfaces and mating interfaces.

- 5-axis simultaneous machining efficiently handles deep-cavity parts and complex undercut geometries

- In-process CMM inspection guarantees compliance with GD&T standards for every production batch

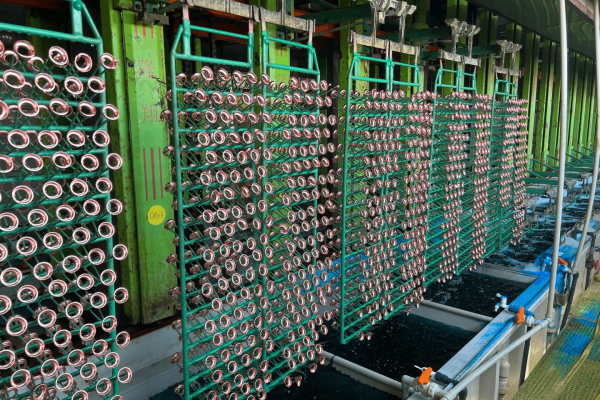

Die Casting Surface Finishing

Achieve Ra0.2μm mirror finishes via multi-stage polishing or opt for fingerprint-resistant textured coatings through anodization.

- Custom PVD coatings (e.g., TiN/CrN) provide wear resistance up to 1,200HV in harsh environments

- RoHS-compliant electrophoretic coating delivers over 500-hour salt spray corrosion resistance

CastMold Die Casting Capabilities

Excellent Die Casting Quality

Through strict quality control measures and precise rejection criteria, our production system guarantees dimensional accuracy and aesthetic integrity in every casting. By implementing quantifiable surface finish standards, we ensure quality alignment between design specifications and manufactured components.

- Dimensional metrology (CMM with ±2μm repeatability)

- Material verification (XRF spectrometry compliant with ASTM E1621)

- Structural integrity testing (X-ray/CT scanning for porosity ≤0.2%)

- Environmental compliance (RoHS/REACH certification)

- Corrosion resistance validation (1000hrs salt spray testing per ASTM B117)

Die Cast Parts Engineering Support

CastMold’s seasoned engineering team partners with clients from concept development to mass production, delivering design-driven manufacturing excellence.

DESIGN-TO-PRODUCTION ENGINEERING SOLUTIONS

Our engineers leverage advanced CAE simulations and 20+ years of die-casting expertise to:

- Optimize product/tooling designs for manufacturability using CAD/CAM integration

- Conduct mold flow analysis to prevent defects (porosity, warping) during filling/solidification

- Streamline prototyping-to-production transitions through virtual verification systems

- Implement value engineering strategies for cost-efficient material usage and process optimization

- Proficiency in Pro/Engineer and parametric modeling ensures seamless translation of digital designs into high-performance tooling and cast components.

Basınçlı Döküm

Products Gallery

From compact high-tolerance components (±0.05mm) to heavy-duty structural assemblies, we engineer defect-free die-cast parts in aluminum/zine alloys for automotive, robotics, and consumer electronics.

EV Charging Port

Lightweight die-cast charging interface

Aluminum alloy ensures thermal management for fast charging, corrosion-resistant & automotive-grade compliance

Spotlight Lightbox

Seamless die-cast outdoor lightbox

IP65-rated aluminum housing with lightweight durability reduces installation complexity

Telefon Tutucu

Çok amaçlı döküm tutucu

Kaymayı önleyici silikon ile güçlendirilmiş alüminyum çerçeve, deformasyona ve aşınmaya karşı dayanıklı

Communication Housing

5G base station die-cast enclosure

EMI-shielded aluminum with heat dissipation, precision tolerance for critical deployments

Industrial Coupling

Extreme-condition die-cast couplings

High-strength alloy withstands -40℃~200℃, low porosity enhances fatigue resistance

Coffee Machine Housing

Food-safe die-cast body

Lead-free aluminum withstands high heat, compliant with commercial hygiene protocols

Types of Die Casting Processes

CastMold delivers tailored die casting solutions through Hot Chamber and Cold Chamber Die Casting technologies, optimized for diverse materials (aluminum, zinc) and production scales. Our expertise ensures seamless adaptation to your project’s structural complexity, volume demands, and cost targets.

![热室压铸 {"source_type":"douyin_beauty_me","data":{"capability_key":[],"playId":"","enter_from":"enter_launch","infoStickerId":"","filterId":"","stickerId":"","imageEffectId":"","alias":"f2hooZ9BhRn1JeFSvdYpY/JFx3yKZrG2mLbk5Tk5hfZ8eFDI3TrwADuYO24OGME1/zLp8r2eUSxbCm6BvLN7DJlc1AqH29VE80BIsfPC4D8FuDmgKcVmG/QHZxffvuFCJWEOugqR0Kiq9wXgXdYpF+bSSfvFOk8Oo0FAjS6nEHcFB/WJLT3gZBn1OjLPEwNJbJnOCi0CNDXfQXlk5NnFlPNvbBOaNT1XQxGLbLLSDhIUJJ3RO6CGbEAeXQHrvQf90+gcrSTnF+eCfmbx/Cyl+eP84llY91LYFUkD7epR1zp2Z4YaXolXqkZMQeOK0V3uQk7cIJA8mOniUrYn2NdSEg==","product":"retouch","activityName":"","capability_extra_v2":{},"pictureId":"26D343B4-9EDB-4CE9-AEB3-319AC9698E96","appversion":"11.8.0","os":"ios"}}](https://cast-mold.com/wp-content/uploads/elementor/thumbs/热室压铸-r2uf6rdmdx1nepeikxn9meqgqbzprap4o54utbkq48.jpg)

Hot Chamber Die Casting

Cold Chamber Die Casting

Uygulamaları

Alüminyum Basınçlı Döküm

- Automotive:Engine components (e.g., cylinder heads, transmission housings), Electric vehicle battery enclosures and structural parts

- Consumer Electronics: Heat sinks, housings for laptops, and 5G communication devices

- Aerospace: Lightweight brackets, sensor housings, and UAV components

- Industrial Machinery: Pump housings, hydraulic valves, and robotic arm parts

- Renewable Energy: Solar panel frames, wind turbine gearbox components

Advantages of

Alüminyum Basınçlı Döküm

- Lightweight Strength: High strength-to-weight ratio (e.g., ADC12 alloy with 230+ MPa tensile strength).

- Corrosion Resistance: Natural oxide layer ensures durability in harsh environments.

- High Thermal: Conductivity Ideal for heat dissipation in electronics and automotive systems.

- Precision & Complexity: Tolerances as tight as ±0.1mm for intricate geometries.

- Sustainability: 100% recyclable material with reduced energy consumption vs. steel.

Disadvantages of

Alüminyum Basınçlı Döküm

- High initial tooling costs: Complex mold designs and high-pressure die-casting machines require significant upfront investment, limiting small-batch production viability.

- Design limitations for thin walls: Fluidity challenges in molten aluminum restrict ultra-thin wall designs (<1mm), impacting lightweight optimization in some applications.

- Internal porosity risks: Rapid cooling during casting can create micro-voids, potentially compromising structural integrity for high-stress components.

- Limited high-temperature performance: Aluminum's lower melting point (660°C) and thermal conductivity make it unsuitable for extreme heat environments vs. steel/titanium alloys.

- Surface finishing requirements As-cast surfaces often require secondary machining/anodizing to achieve precise tolerances or corrosion resistance, adding production steps.

SSS

Die casting is a metal casting process where molten metal is forced under high pressure into a reusable steel mold cavity. The mold, composed of two hardened dies, operates similarly to an injection mold, enabling high-volume production of small to medium-sized parts with excellent surface finish and dimensional consistency. Key steps include melting the metal (commonly aluminum, zinc, or magnesium alloys), injecting it into the die under high pressure, and cooling to form the final part.

This process is widely used in automotive manufacturing for lightweight, complex components like engine blocks and structural frames. For example, Tesla employs 6,000-ton gigacasting machines for front and rear underbody parts, while AITO M uses a 9,000-ton press for rear sections1. Advantages include cost-effectiveness (due to reusable dies), rapid production cycles, and high structural integrity.

1. Wall Thickness

Maintain uniformity (2.5–4 mm for aluminum alloys), avoid thick sections (>6 mm) to prevent gas porosity; use ribs/gussets instead of localized thickening, and ensure gradual transitions to reduce stress.

2. Draft Angle

Minimum 0.25°–1.5° (1°–3° for deep cavities or textured surfaces); align draft direction with mold opening to avoid undercuts.

3. Fillets

Internal radii ≥0.5 mm (recommended: 1/2 to full wall thickness) to enhance strength and fill; round external edges for easier mold maintenance.

4. Gating System

Place gates near thick sections for laminar flow to minimize air entrapment; tapered runners and small gates require high pressure but simplify trimming.

5. Venting

Add 0.1–0.15 mm deep vent slots along the parting line; critical components use vacuum-assisted systems with dual vents to reduce porosity.

6. Geometric Simplification

Eliminate undercuts, optimize parting lines for minimal complexity, and adopt symmetry to reduce thermal distortion and improve mold stability.

The tolerances for die casting vary depending on the process and part dimensions. For pressure diecasting, the flatness tolerance is typically 0.2 mm for dimensions up to 75 mm, with an additional 0.075 mm added per 25 mm increase in size4. These values reflect standard production practices optimized for cost-effectiveness. Higher precision may require specialized processes or additional post-casting machining. For example, surface roughness in high-pressure die casting can achieve Ra 1.6–6.3 μm under optimal conditions1, though dimensional tolerances remain primarily governed by the casting size and material flow characteristics. Designers should specify tighter tolerances only where functionally necessary, as achieving them often increases production complexity.

Our design team utilizes specialized software for product development and mold flow analysis, ensuring designs meet production requirements. Through pre-production simulations, we optimize processes to reduce trial runs and improve yield.

We are well-versed in PPAP processes and can prepare complete Production Part Approval documentation, guiding clients through the review procedures.

ISO 9001:2015 sertifikalı kalite yönetim sistemimiz, ilk madde denetimi, süreç içi kontroller ve son denetim dahil olmak üzere hammaddeden bitmiş ürüne kadar tam süreç takibi sağlar.

Yıllık iyileştirme planları uyguluyor, müşteri geri bildirimleri ve üretim verileri analizi yoluyla süreçleri ve verimliliği düzenli olarak optimize ediyoruz.

Biz teklif ediyoruz 2-10 haftalık esnek teslim süreleritasarım karmaşıklığına ve müşteri gereksinimlerine göre uyarlanmıştır. Paralel tasarım onayı ve modüler üretim çözümleri sayesinde, standart projeler aşağıdaki sürelerde teslim edilebilir 2 hafta gibi kısa bir süredeiçinde tamamlanan karmaşık projeler ile Maksimum 10 hafta.