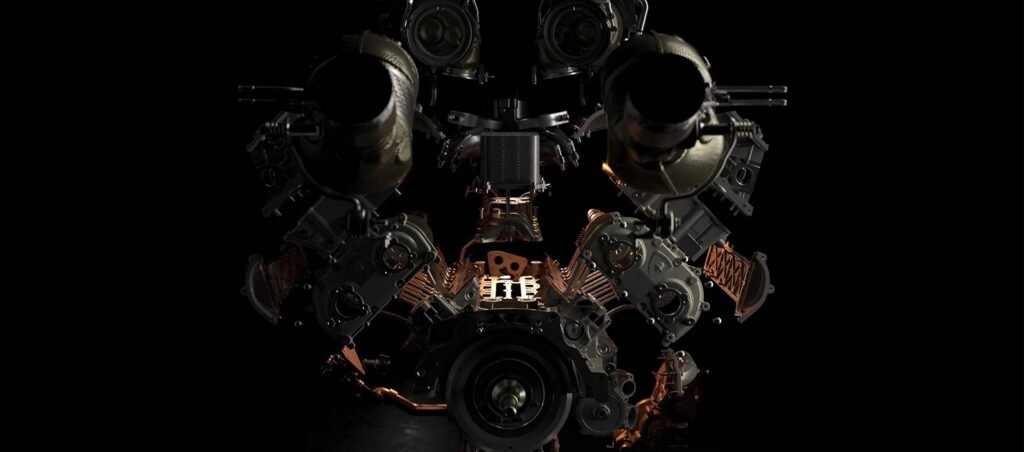

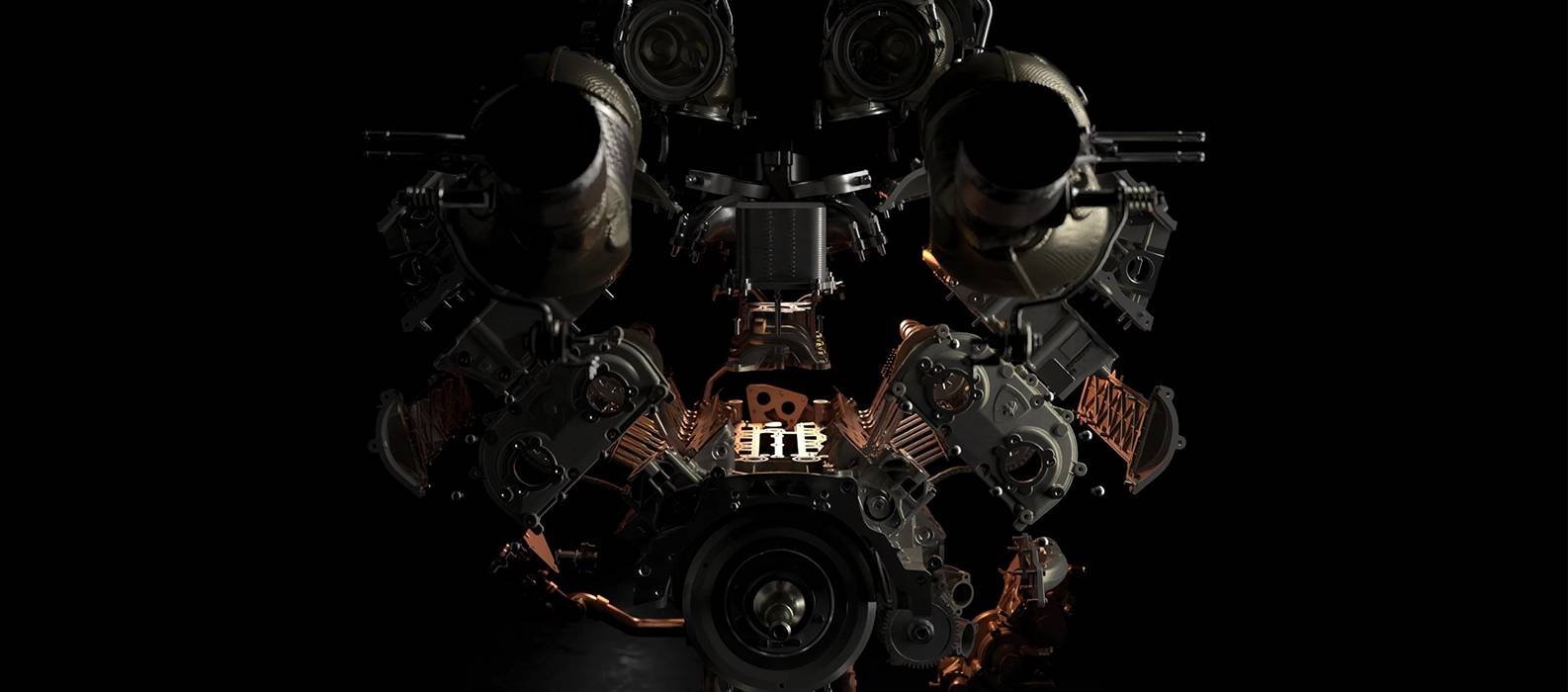

Not all supercar magic comes from software or batteries. A huge part of Lamborghini’s new Temerario (the “Little Bull”) is good old—yet very modern—aluminum die casting and casting science. From a copper-tuned alloy in the L411 4.0L twin-turbo V8 block to 3D-printed sand cores inside the cylinder head—and from compact cast gearbox housings to a stiffer aluminum frame—this car is a clinic in how casting enables performance, packaging, and reliability.

Below I’ll unpack the hybrid layout briefly, then dive into the casting stack: alloy engineering, process selection (HPDC vs. sand casting), thermal treatment choices (T4/T5/T6), the role of printed cores, and what all of this means for engineers planning the next high-performance ICE-hybrid or performance EV.

- Key Takeaways

- The Hybrid Layout (Quickly): Why Casting Still Matters

- Alloy Engineering: Why Tweak A357 with Copper?

- HPDC vs. Sand Casting: Picking the Right Process for Each Part

- Thermal Treatments (T4/T5/T6): Why T5 Makes Sense on HPDC

- 3D-Printed Sand Cores in the Cylinder Head: Form Follows Flow

- Castings in the Hybrid Driveline: Housings, Covers, and Carriers

- Aluminum Frame & Torsional Stiffness: Casting + Composites = Gains

- Reliability at 10,000 RPM: What Casting Has to Withstand

- Common Casting Risks & How You Control Them (So Your Engine Lives)

- Why Axial-Flux + Casting Belong Together

- What We Can Learn

- Quick Reference: Which Casting Where?

- Perguntas frequentes

- Work with CastMold

- Aluminum Die Casting Services

Key Takeaways

- Aluminum die casting (HPDC) and sand casting are both used where they’re strongest: thin-walled housings and high-volume parts for HPDC; complex water jackets and exhaust passages via 3D-printed sand cores for heads.

- Lamborghini reportedly micro-alloyed a classic casting grade (A357 family) with copper for better creep resistance at high temperature—trading a narrower casting window and tougher process control for high-rpm stability.

- The engine program leans on T5 artificial aging (no full solution treatment) to avoid blistering/distortion typical of HPDC porosity under T6—while still gaining dimensional stability and usable strength.

- Packaging wins (transverse gearbox, axial-flux P1 motor, distributed P4 front e-motors) depend on cast housings with tight tolerances, stiffness, and heat management built in.

- The Temerario’s aluminum frame (with carbon reinforcements) gains ~23% torsional rigidity vs. Huracán at similar weight—exactly what casting + intelligent materials are supposed to deliver.

The Hybrid Layout (Quickly): Why Casting Still Matters

Yes, there’s a lot of electrification tech: a longitudinal V8 with a rear power take-off to a transverse 8-DCT, a P1 axial-flux motor (YASA-type) between engine and gearbox, and two distributed front e-motors (P4). That sleek packaging only works if housings, carriers, covers, and brackets are thin, stiff, and accurately cast—and if cooling jackets and oil circuits are routed through near-net-shape cast geometry. In short: casting is the enabler for compact driveline and thermal management in a mid-engine hybrid.

Alloy Engineering: Why Tweak A357 with Copper?

A357 (Al-Si-Mg) is a go-to for castings that need good strength and corrosion resistance, especially when heat treated. For a 10,000-rpm flat-plane V8 that sees high local temperatures and sustained loading, Lamborghini aimed for better creep resistance—the ability of the block to hold shape under heat + stress over time. That’s reportedly where Cu micro-alloying comes in:

- Pros: boosts high-temp structural integrity, dimensional stability for bores and main webs, more consistent head-gasket sealing at sustained load.

- Trade-offs: narrower casting window, higher shrinkage/porosity risk, potentially more difficult corrosion behavior to manage. Process control (melt cleanliness, degassing, gating/feeding) has to be on point.

What this means for you: if you’re pushing high BMEP or elevated coolant/oil temps, micro-alloying can keep geometry stable—but it tightens your process latitude. Budget for more simulation (flow/solidification), stricter melt treatment, and more NDT (X-ray/CT).

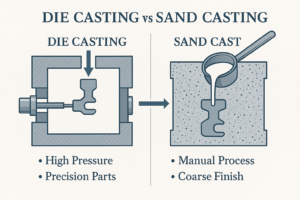

HPDC vs. Sand Casting: Picking the Right Process for Each Part

Fundição sob pressão de alta pressão (HPDC)

- Best for: thin walls (≈1–3 mm), high volumes, tight tolerances, smooth surfaces on covers, housings, carriers, pump bodies, inverter/gearbox casings.

- Why it works here: hybrid driveline enclosures need precision and repeatability—HPDC delivers, with cycle times measured in seconds and near-net shapes that minimize machining.

- Heat treatment reality: standard HPDC micro-porosity makes T6 risky (blistering). T5 (artificial age from casting heat) is safer for dimensional stability without gas “pop-outs”.

Sand Casting (with 3D-Printed Cores)

- Best for: cylinder heads and complex internal flow parts—water jackets, integrated exhaust manifolds (IEM), tortuous oil galleries.

- 3D-printed ceramic/sand cores let you shape impossible passages with smooth surfaces and tight dimensional control inside the casting, then break the core out (“sacrificial core”).

- Reality check: the head is still machined—valve seats, guides, sealing faces. Printing the whole head in metal would be astronomically costly and still need machining on functional surfaces.

Bottom line: Use HPDC where thin, stiff, accurate shells win the packaging game. Use sand/printed cores where fluids and thermals demand complex internal topology.

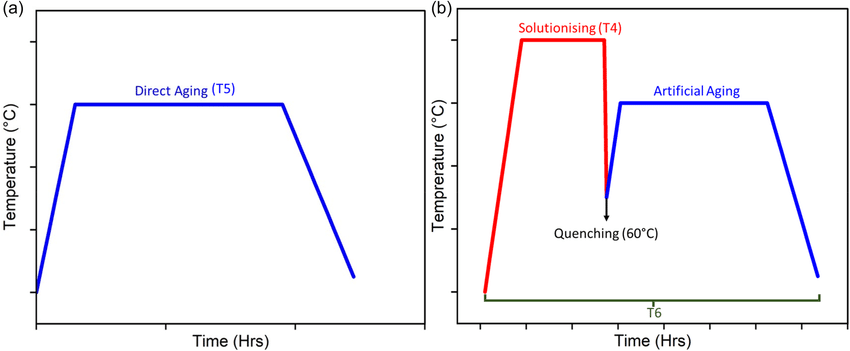

Thermal Treatments (T4/T5/T6): Why T5 Makes Sense on HPDC

Quick refresher:

- T4: Solution treat (~540–555 °C) + natural age.

- T6: Solution + quench + artificial age (max strength, but risky for porous HPDC due to blistering/distortion).

- T5: Artificial age only after casting, leveraging residual heat.

For HPDC engine blocks or housings, T5 is often the sweet spot:

- Avoids gas expansion blisters that sink parts in T6.

- Improves dimensional stability (bores stay rounder, decks stay flatter).

- Delivers a usable strength/ductility balance for highly stressed but thin-walled parts.

If you need T6-class strength, pick a process/alloy combination that naturally minimizes porosity (e.g., vacuum-assisted HPDC, permanent mold) and design your gating/venting obsessively.

3D-Printed Sand Cores in the Cylinder Head: Form Follows Flow

Printing the core, not the metal, is the winning move here:

- Why: You can route original, optimized water jackets and exhaust runners that reduce pressure loss, control hot spots, and cut knock tendency—exactly what a 9,000–9,750 rpm peak power band needs.

- How: Ceramic or specialty sand is binder-jetted/layer-printed into intricate cores; molten aluminum is poured around it; after solidification, the core is washed/broken out.

- Result: A head blank whose internals match CFD intent, then CNC’d to final form where precision matters.

No, we’re not printing heads whole for series production. Not yet. The resolution, porosity, and cost realities keep printed cores as the smart compromise.

Why can a single drawing determine the type of sand core?

The judgment is based on five points:

- Shape insight: Presence of strict draft angle limitations.

- Geometric complexity: Fishbone-shaped channels are difficult to produce with traditional cores.

- Asymmetrical connections: Clear asymmetrical links between channels.

- Trapped-core geometry: Existence of geometries that create “trapped core” situations impossible for conventional cores.

- Multiple inlets and outlets: Almost no possibility of using traditional cores.

Castings in the Hybrid Driveline: Housings, Covers, and Carriers

The Temerario’s driveline depends on cast aluminum parts to hit stiffness and packaging targets:

- Transverse 8-DCT housing: HPDC or permanent-mold cast shell with integrated galleries, bosses, and mounts.

- P1 motor adapter & bellhousing: thin-wall castings hold alignment, manage NVH, and leave room for cooling jackets.

- Front e-motor modules: compact cast enclosures allow axial-flux hardware up front without wrecking aero or suspension pick-up points.

Casting lets you consolidate parts (fewer fasteners and joints), keep tolerances tight, and channel fluids through the structure—all vital in a mid-engine hybrid where every millimeter counts.

Aluminum Frame & Torsional Stiffness: Casting + Composites = Gains

The “Little Bull” sticks to an aluminum frame with carbon reinforcements (floor, B-pillar, firewall). Lamborghini states the body-in-white torsional rigidity is up ~23% vs. Huracán at similar weight. That kind of step usually needs cast nodes, precision extrusion-to-casting joints, and smart joining (adhesives + fasteners). Again: casting makes load paths clean and stiffness predictable—so aero, suspension, and tire models work as designed.

Reliability at 10,000 RPM: What Casting Has to Withstand

A flat-plane V8 at 10k rpm is not polite. Vibratory modes, oil aeration, thermal expansion deltas—everything wants to move. Casting choices directly affect:

- Main web strength and bore roundness under heat/cycle.

- Cap bolt boss integrity and thread pull-out behavior.

- Coolant jacket shape to avoid nucleate boiling near exhaust bridges.

- NVH pathways (cast ribs and closed sections) that make or break sound character.

Then there’s the torsional damper strategy (lighter than a balance shaft) and hollow high-strength shafts (e.g., carburized 300M) spanning dual-mass flywheel → P1 motor → gearbox: all of it lives or dies on the accuracy and stability of the cast mating faces and locators.

Common Casting Risks & How You Control Them (So Your Engine Lives)

- Porosity / Air Entrapment (HPDC): Use vacuum die casting, vent design, high-cleanliness melt (degassing, fluxing), disciplined die temperature and fill speed.

- Shrinkage / Hot Spots (Sand/PM): Use chills, uniform sections, proper feeders, and riser sleeves; simulate solidification (MAGMA/Flow-3D).

- Soldering / Die Erosion (HPDC): Coatings (e.g., nitrided/H13 with advanced ceramics), controlled lube cycles, stable die temperatures.

- Dimensional drift after heat: Prefer T5 on HPDC; target bores and decks with fixtured artificial aging; machine with temperature control.

- Corrosion uncertainty (Cu-added alloys): Validate with salt-spray & cyclic corrosion tests; specify coatings (anodize/Alodine/powder) where needed.

Why Axial-Flux + Casting Belong Together

Axial-flux e-motors win on power density (thin, pancake form). Putting them in the front axle of a mid-engine hybrid makes sense only if you free volume for aero, ducting, and cooling. That demands tight, thin-wall castings around the motor + gearbox + inverter—precisely what HPDC is good at. Less frontal area, cleaner under-nose flow, and lower CG are all casting-enabled outcomes.

What We Can Learn

- Design for Casting Early: Treat casting like you treat aero or control systems—bring foundry engineers into concept freeze.

- Use printed cores strategically: Heads, charge-air coolers, integrated manifolds—print where fluid path beats the old drill-and-plug approach.

- Pick T5 when HPDC rules: If you need volume + thin walls, don’t force T6; design strength into geometry, ribs, and webs.

- Prototype in sand, scale in HPDC: Prove combustion/thermal layouts in sand-cast heads/blocks; migrate housings and covers to HPDC for SOP.

- Invest in melt & mold discipline: High-rpm reliability is mostly process control: dross management, hydrogen control, die thermal management, and closed-loop shot control.

Quick Reference: Which Casting Where?

| Powertrain Part | Recommended Process | Why It Works |

|---|---|---|

| Gearbox housings / bellhousings | HPDC / PM | Thin walls, tight tolerances, good NVH + fluid galleries |

| Inverter/E-drive enclosures | HPDC | Repeatability, sealing surfaces, heat-spreader geometry |

| Engine block (high-rpm hybrid) | HPDC (with T5) or PM | Volume + stiffness; T5 for dimensional stability; PM for lower porosity |

| Cylinder head (complex jackets) | Sand casting + 3D cores | Intricate cooling + IEM passages; machinable after casting |

| Mounts, brackets, carriers | HPDC | Consolidation, weight reduction, lower assembly count |

| Frame nodes / subframe joints | Cast nodes + extrusions | Stiffness at low mass, clean load paths |

Perguntas frequentes

Because cost, resolution, porosity, and thermal stress still demand heavy machining on functional surfaces. Printed cores give you 90% of the internal geometry benefit for 10% of the cost.

Standard HPDC porosity makes T6 risky. You can do it on specialty vacuum HPDC parts, but most high-volume programs favor T5 for stability and yield.

Creep resistance at temperature. But you’ll face a narrower casting window and tighter corrosion/porosity control. It’s a trade you make for high-rpm integrity.

Work with CastMold

If you’re exploring micro-alloyed casting, printed core heads, or HPDC housings for high-performance hybrids, bring us in early. CastMold can help you co-design for casting, simulate flow/solidification, and lock in a robust T5-based path that hits your strength, stiffness, and NVH targets—without killing yield.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.