Blog

Welcome to our blog for insights into different manufacturing processes.

- Home

- blog

A413 Aluminum Alloy: Achieving Superior Pressure Tightness in Die Casting

A413 aluminum delivers pressure-tight, leak-free die castings; high fluidity and low shrinkage enable thin-wall housings, pump/compressor parts, and reliable sealing……

PVD vs CVD vs ALD: 7 Essential Differences for High-Performance Thin Film Deposition

Die Casting Part Design: 14 Structural Principles for DFM & DFA

Surface Finishing Processes: 7 Effective Methods in One Guide

How to Use Numerical Simulation to Prevent Defects in Large Die Castings: 5 Powerful Lessons from Automotive HPDC

All Articles

Why the iPhone 17 Pro Returned to Aluminum: A Systemic Analysis of Material, Process, and Thermal Management

iPhone 17 Pro’s 7000-series aluminum unibody and integrated vapor chamber rebuild the thermal path for A19 Pro and on-device AI—delivering......

Zinc Die Casting Zamak Alloy: Why It Wins

Zamak alloy in zinc die casting: why it wins on thin walls, cycle time, die life, plating-ready finishes, and repeatability—plus......

A413 Aluminum Alloy: Achieving Superior Pressure Tightness in Die Casting

A413 aluminum delivers pressure-tight, leak-free die castings; high fluidity and low shrinkage enable thin-wall housings, pump/compressor parts, and reliable sealing.......

B390 Aluminum: The High-Silicon Alloy for Unmatched Wear Resistance

B390 aluminum: a hypereutectic Al-Si grade with very high wear resistance, high hardness, low thermal expansion and good seizure resistance,......

A360 Aluminum Alloy: THE BEST for Corrosion Resistance

A360 aluminum alloy offers best-in-class corrosion resistance, pressure-tightness, and fluidity for thin walls—ideal for outdoor, marine, and die-cast housings.......

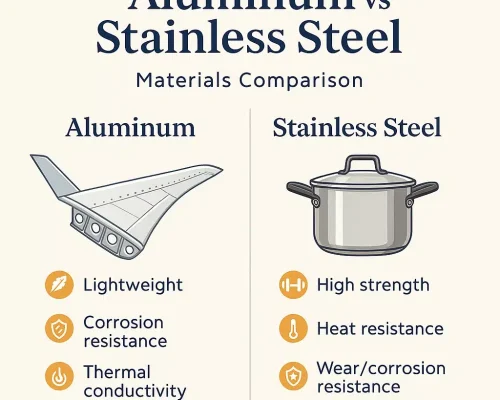

Aluminum vs Stainless Steel: 7 Key Differences for Your Project

Which is better for your design—aluminum or stainless steel? See pros/cons, strength-to-weight, corrosion, heat, cost, finishes, and when to pick......

ADC12 Aluminum Alloy (A383/AC-46100): Properties, Composition, and When to Use It

ADC12 aluminum excels in HPDC with great fluidity, crisp feature replication, balanced strength, dimensional stability, easy machining, and finishes that......

A380 Aluminum Alloy: Properties, Composition, and When to Use It

Practical guide to A380 aluminum: advantages, limitations, heat-treat options, and DFM tips for high-volume die-cast parts.......

6 Types of Aluminum Die Casting Alloys—Which’s the Right Choice for Your Design?

Grades compared in one place: mechanicals, porosity risk, finishing options, and selection tips for aluminum die casting alloys.......