When designing components for high-wear environments, material selection is critical. For engineers seeking an aluminum die casting alloy that offers exceptional hardness and abrasion resistance, B390 aluminum is a standout choice. This guide provides a data-driven overview of B390’s properties, applications, and manufacturing considerations, helping you determine if it’s the right fit for your project.

What is B390 Aluminum Alloy?

B390 is a specialized aluminum die casting alloy recognized for its extremely high silicon content. This unique composition places it in a specific category of materials known for durability under friction and stress.

The Secret to Its Strength: High Silicon Content

B390 is classified as a hypereutectic aluminum-silicon alloy. This means its silicon (Si) content, ranging from 16% to 18%, exceeds the eutectic point of 12.6%. During solidification, this excess silicon precipitates as hard, primary silicon particles distributed throughout the aluminum matrix. These particles act as microscopic, load-bearing surfaces, providing the alloy with its signature high wear resistance and excellent hardness. The size, morphology, and distribution of these silicon precipitates are critical process control parameters, often characterized using advanced techniques like scanning electron microscopy (SEM) to ensure the material meets its demanding performance specifications.

B390 Aluminum Chemical Composition

The Critical Role of 16-18% Silicon

The high silicon level is the defining feature of B390. It provides:

- Exceptional Wear Resistance: The primary silicon particles create a hard surface that resists abrasion and scuffing.

- Improved Castability: High silicon content enhances the fluidity of the molten metal, allowing it to fill complex and thin-walled sections of a die cast mold.

- Low Coefficient of Thermal Expansion: This provides crucial dimensional stability in components subjected to temperature fluctuations, such as engine parts.

Composition Breakdown Table (B390 vs. A380)

Here’s how B390 compares to A380 (a widely used general-purpose die casting alloy), highlighting the key differences.

| Element | B390 (wt%) | A380 (wt%) | Key Influence in B390 |

|---|---|---|---|

| Silicon (Si) | 16.0 – 18.0 | 7.5 – 9.5 | Drastically increases wear resistance & hardness |

| Copper (Cu) | 4.0 – 5.0 | 3.0 – 4.0 | Increases strength and thermal conductivity |

| Magnesium (Mg) | 0.45 – 0.65 | ≤ 0.1 | Enhances strength and corrosion resistance |

| Iron (Fe) | ≤ 1.3 | ≤ 1.3 | Prevents die soldering |

| Manganese (Mn) | ≤ 0.5 | ≤ 0.5 | Improves strength |

| Zinc (Zn) | ≤ 1.5 | ≤ 3.0 | Contributes to strength |

| Nickel (Ni) | ≤ 0.1 | ≤ 0.5 | — |

| Titanium (Ti) | ≤ 0.2 | — | Grain refinement |

Mechanical & Physical Properties of B390

B390’s properties make it a high-performance material, but its trade-offs must be thoroughly understood during the design phase.

[Image: Bar chart comparing the mechanical properties of B390 and A380 aluminum] B390 provides significantly higher hardness and yield strength than A380, at the cost of extremely low ductility.

Unmatched Wear Resistance & Hardness

With a Brinell hardness of approximately 120 HB, B390 is significantly harder than A380 (around 80 HB). This superior hardness is a direct result of its composite-like microstructure, where the hard silicon phase reinforces the softer aluminum matrix. This makes it the premier choice for applications like sleeveless engine blocks, where pistons run directly against the cylinder bore.

Low Ductility: A Critical Design Consideration

The most significant trade-off for B390’s hardness is its very low ductility. With an elongation at break of less than 1%, the alloy is brittle. This means it is not suitable for components that require plastic deformation (formability) or must withstand significant impact forces. Designers must account for this brittleness to prevent catastrophic failure under load.

Thermal Properties & Performance

B390 offers good thermal conductivity (approx. 130 W/m-K), which is essential for dissipating heat in applications like engine components and compressors. Its low thermal expansion coefficient also ensures that parts maintain their intended clearances and tolerances during thermal cycling.

B390 Properties Data Table

| Property | Value | Units | Notes |

|---|---|---|---|

| Ultimate Tensile Strength | ~317 (46) | MPa (ksi) | As-cast condition |

| Yield Strength | ~248 (36) | MPa (ksi) | Significantly higher than A380 |

| Elongation at Break | < 1 | % in 2 in. | Very brittle, a key design factor |

| Hardness | ~120 | Brinell (HB) | Excellent for wear applications |

| Density | ~2.71 | g/cm³ | Lightweight |

| Thermal Conductivity | ~130 | W/m-K | Good heat dissipation |

| Melting Point (Avg.) | ~580 | °C | — |

Common Applications for B390 Aluminum

B390 is specified where abrasion resistance is the primary engineering requirement and failure mode.

- Automotive Powertrains: The classic application is for sleeveless aluminum engine blocks, pistons, and cylinder liners. Its hardness allows direct contact with piston rings, eliminating the need for heavier cast iron liners and contributing to vehicle weight reduction and improved thermal efficiency.

- Industrial Machinery: Used in compressor components, pump housings, brake parts, and valve bodies that experience sliding friction.

- When to Choose B390 Over Other Alloys: Select B390 when your component will fail from wear or abrasion long before it fails from fatigue or impact. If toughness and ductility are needed, an alloy like A380 or a different manufacturing process may be more suitable.

High-Pressure Die Casting (HPDC) with B390

B390’s high fluidity makes it well-suited for the HPDC process. However, its abrasive nature requires special considerations for tooling and process control.

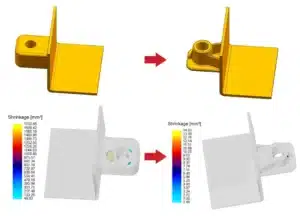

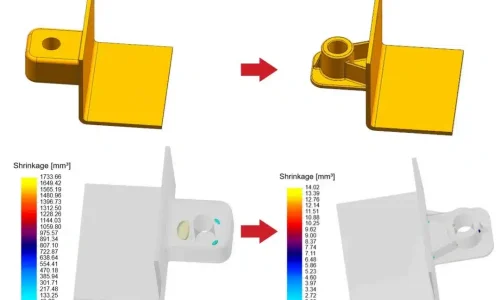

DFM Checklist for B390 Aluminum Components

- Generous Radii: Use larger fillet radii than with more ductile alloys to mitigate stress concentrations.

- Uniform Wall Thickness: Avoid abrupt changes in section thickness to ensure consistent cooling and prevent internal stresses.

- Draft Angles: Incorporate adequate draft (1-2 degrees) to facilitate part ejection and minimize stress on the brittle casting.

- Die Material: Use robust, wear-resistant tool steels (e.g., H13) for the mold, as the high silicon content of B390 is abrasive to tooling.

Common Defects & Prevention Strategies

- Hot Cracking: The alloy’s low ductility makes it susceptible to cracking during cooling.

- Prevention: Optimize die cooling, ensure proper part ejection, and design parts with smooth transitions.

- Porosity: As with all die castings, trapped gas can cause porosity.

- Prevention: Utilize vacuum-assisted HPDC, optimize shot parameters, and ensure proper venting in the mold.

Machining and Surface Finishing for B390 Aluminum

Challenges in Machinability

The hard primary silicon particles that give B390 its wear resistance also make it difficult to machine. Cutting tools experience rapid wear.

- Best Practice: Use polycrystalline diamond (PCD) or carbide-tipped tooling.

- Operation: Slower speeds and controlled feeds are necessary to achieve a good surface finish and avoid tool breakage.

Surface Treatment Limitations

B390 is a poor candidate for decorative or protective anodizing. The high silicon content results in a non-uniform, dark gray finish. For corrosion protection, consider alternatives like:

- Powder Coating

- E-Coating

- Chromate Conversion Coating

FAQs

Your Partner for B390 Die Casting

Choosing the right high-performance alloy is crucial for demanding applications. B390 aluminum offers a unique solution where wear resistance is paramount, but its specific manufacturing requirements demand expertise.

If you are considering B390 for your next project, our engineering team can provide the DFM support and process control needed to deliver high-quality, reliable components.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.