The aluminum melting point isn’t just a number—it’s a critical factor influencing design, processing, performance, and procurement decisions across industries. For engineers and procurement managers, understanding this thermal threshold enables smarter alloy selection, better production planning, and cost-effective material sourcing.

What is the Aluminum Melting Point?

The aluminum melting point is precisely 660.3°C (1220.5°F). Unlike pure aluminum, industrial aluminum alloys have melting ranges influenced by elements like silicon, copper, magnesium, and zinc, significantly affecting their practical usability and processing conditions.

Typical Aluminum Alloys Melting Points:

In industrial applications, aluminum alloys are processed through a variety of manufacturing methods—each with distinct performance and material requirements. Among them, die casting, sand casting, and wrought processing are the most widely used. Each method demands specific alloy characteristics: die casting requires high fluidity and excellent castability, sand casting favors alloys suitable for large and complex geometries, while wrought alloys are optimized for deformation processes like extrusion or rolling. The melting point of each alloy plays a critical role in determining its suitability for these processes.

Below is a breakdown of typical melting points across commonly used aluminum alloys, organized by processing method:

Die Casting Aluminum Alloys

| Alloy Name | Melting Range (℃) | Melting Range (℉) | Key Properties |

| A380 | 538-593 | 1000-1100 | Excellent castability, moderate strength, good corrosion resistance |

| ADC12 | 570-610 | 1058-1130 | High fluidity, excellent die filling, commonly used in Asia |

| A360 | 550-610 | 1022-1130 | Superior corrosion resistance, good pressure tightness |

| A413 | 560-610 | 1040-1130 | High pressure tightness, low porosity, used for fluid components |

| B390 | 510-595 | 950-1100 | Very high wear resistance, poor ductility |

Sand Casting Aluminum Alloys

| Alloy Name | Melting Range (°C) | Melting Range (°F) | Key Properties |

| A356 | 557–613 | 1035–1135 | Heat-treatable, good ductility, excellent for structural parts |

| A357 | 545–610 | 1013–1130 | Higher Mg, better strength, aerospace use |

| 319 | 540–595 | 1004–1103 | Good machinability, widely used in automotive castings |

| 443 | 540–590 | 1004–1094 | Good corrosion resistance, general-purpose casting |

| C355 | 552–610 | 1025–1130 | High strength and good toughness, aircraft and automotive |

Wrought Aluminum Alloys

| Alloy Name | Melting Range (°C) | Melting Range (°F) | Key Properties |

| 6061 | 582–652 | 1080–1206 | Good strength and weldability, widely used |

| 7075 | 477–635 | 890–1175 | Very high strength, aerospace grade |

| 5052 | 607–650 | 1125–1202 | Excellent corrosion resistance, marine and automotive use |

| 2024 | 500–638 | 932–1180 | High fatigue resistance, aerospace |

| 3003 | 643–655 | 1190–1211 | Excellent formability, general purpose |

How Aluminum Melting Point Influences in Key Processes

High-Pressure Die Casting (HPDC)

The relatively low aluminum melting point (around 660°C for pure aluminum) makes it ideal for high-pressure die casting (HPDC). Typically, alloys like A380 melt between 538–593°C, allowing efficient molding with steel dies. Strict thermal control (680–700°C) is crucial to prevent defects like porosity or mold damage.

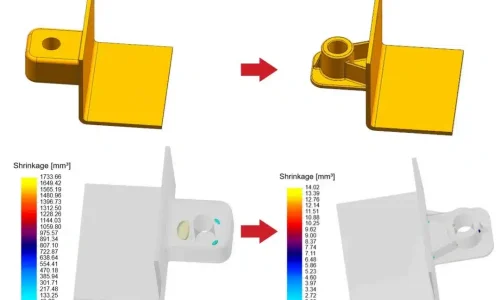

Sand Casting and Permanent Mold Casting

These gravity-fed processes benefit from aluminum’s moderate melting point, which allows molten metal to be poured at around 700°C using cost-effective materials like sand or iron molds. However, consistent thermal control is still crucial—pouring the alloy too cool may lead to misruns or incomplete mold filling, while excessive temperatures can result in shrinkage cavities or oxidation. Best practices suggest maintaining a pouring temperature 50–100°C above the alloy’s liquidus point to balance flowability and solidification integrity.

Aluminum Melting Point & Extrusion Processes

For extrusion processes, billets are heated to temperatures (400–500°C) below the aluminum melting point, enabling deformation without melting. This temperature control prevents surface imperfections, especially in alloys with narrow melting windows like 7075.

Welding and Brazing

Aluminum’s relatively low melting point (~660°C) presents both opportunities and challenges in welding. Precision heat input is critical—techniques such as TIG welding with AC current are commonly used to stabilize the arc and reduce burn-through risk. In brazing, filler alloys like Al-12%Si melt at ~577°C, making it essential to select base materials with significantly higher melting thresholds to avoid compromising the structural integrity of the components being joined.

Powder Coating and Thermal Post-Processing

While powder coating involves curing temperatures well below aluminum’s melting point (typically 180–200°C), thermal exposure can still affect the mechanical properties of certain alloys. For example, over-curing or pre-baking temperatures above 250°C may degrade the hardness of heat-treated grades like 6061-T6 by partially annealing the material. Thus, it’s important to match post-processing conditions with the alloy’s thermal sensitivity to preserve final part performance.

How Aluminum’s Melting Point Impacts Manufacturing Decisions

Energy Efficiency and Furnace Optimization

Aluminum’s relatively low melting point—around 660°C—offers a major advantage in manufacturing: reduced energy consumption. Unlike steel or copper, which require significantly higher temperatures to melt, aluminum can be processed in furnaces operating efficiently at 700–750°C. This not only saves on energy bills but also minimizes thermal stress on equipment, resulting in longer furnace lifespans and lower maintenance costs.

Moreover, the recyclability of aluminum is deeply tied to this thermal property. Melting scrap aluminum for reuse requires just 5–10% of the energy needed for primary smelting. As a result, aluminum stands out as one of the most sustainable materials in modern manufacturing, enabling cost-effective circular production systems without sacrificing material performance.

Implications for Tooling, Molds, and Equipment Design

From a tooling perspective, aluminum’s melting behavior defines much of the equipment that surrounds it. The ability to use steel molds and dies—rather than expensive, exotic materials—is a direct benefit of its moderate melting range. Common tooling steels like H13 or 1.2344 can handle the thermal cycling involved in aluminum casting without suffering from premature fatigue or heat damage.

However, maintaining consistent process temperatures is critical. In high-pressure die casting, for instance, the molten aluminum must be held just above its liquidus point (usually around 680–700°C for alloys like A380). If the temperature drops even slightly, defects such as cold shuts or misruns can occur. On the flip side, overheating risks mold degradation through erosion or soldering—where molten metal fuses with the mold surface. This delicate balance demands precision in thermal management strategies, including mold coatings, optimized cooling channels, and real-time temperature monitoring.

Alloy Selection in Temperature-sensitive Applications

The melting point of aluminum doesn’t just affect how it’s cast—it also determines how it performs under operational heat exposure. High-performance alloys like 7075 offer superior mechanical strength but possess narrower melting windows and lower thermal stability, making them unsuitable for environments where temperatures regularly exceed 150°C.

Conversely, more thermally stable alloys such as 6061 or A356 can tolerate higher in-service temperatures while maintaining structural integrity. These alloys are ideal for components exposed to moderate heat loads, such as automotive chassis elements, heat sinks, or enclosures near engines.

Selecting the right alloy, therefore, isn’t just about strength or cost—it requires an understanding of the thermal demands of the end-use environment. A mismatch can result in premature part deformation, microstructural degradation, or catastrophic failure, especially in high-load or cyclic conditions.

How Melting Point Shapes Industry Decisions

Automotive: A Material Optimized for Casting

The automotive sector provides a perfect example of leveraging aluminum’s low melting point. Components like engine blocks, cylinder heads, and transmission housings are often made from A380 or similar alloys, cast efficiently with minimal energy input. The lower melting range accelerates cycle times and reduces overall production costs—especially in high-volume manufacturing.

However, for thermally extreme components—like turbocharger housings, exhaust manifolds, or brake rotors—aluminum is unsuitable. These parts operate well beyond aluminum’s melting temperature and require materials with far higher thermal resistance.

Electronics: Reliable Heat Dissipation with Thermal Safety Margins

Aluminum is widely used in electronic enclosures and heat sinks, where it combines light weight with excellent thermal conductivity. Most electronic components operate below 150°C, a temperature range that’s well within the safety window for alloys like 6061 or ADC12.

During processes such as soldering (which can reach 250°C), it’s essential to avoid softening or deforming the aluminum housing. This is managed through careful alloy selection and design modifications, ensuring that heat-sensitive electronics remain protected without compromising material integrity.

Conclusion: Why Melting Point Matters in Every Decision

Understanding aluminum’s melting behavior isn’t just a theoretical exercise—it’s a cornerstone of effective design, manufacturing, and procurement strategy. From selecting the right furnace temperature to designing molds that last longer, from avoiding thermal distortion in service to optimizing energy costs and recycling strategies, the implications are both broad and deep.

For engineers, mastering aluminum’s thermal profile ensures parts are both manufacturable and reliable.

Ultimately, aluminum’s melting point isn’t just a number—it’s a design constraint, a cost driver, and a performance enabler. And for industries aiming to balance precision, sustainability, and performance, it’s one of the most important properties to understand.