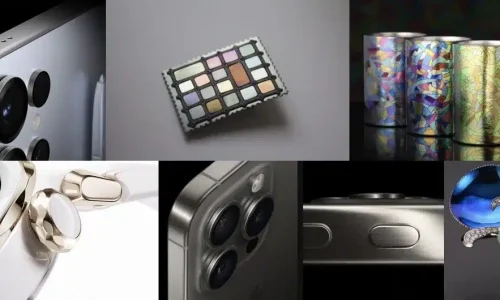

Choosing the right aluminum finishes for your cast components is a critical decision that extends far beyond simple aesthetics. The surface treatment applied to a cast aluminum part has a triple impact, defining its final appearance, its functional performance, and its ability to withstand corrosive environments. For cast aluminum parts, which often have inherent surface imperfections, post-processing is not just an option—it’s an essential manufacturing step to ensure quality and durability.

In this guide, we’ll explore the 7 most commonly used aluminum finishes for cast parts, compare their properties and applications, and show how surface treatments can unlock the full potential of aluminum die casting.

- Why Aluminum Surface Finishing Matters

- Understanding Aluminum Surface Properties Before Finishing

- 7 Types of Aluminum Finishes for Cast Components

- Choosing the Right Aluminum Finish for Your Application

- Common Defects and Quality Control in Aluminum Finishing

- Conclusion: Finishing Strong with Aluminum

- Aluminum Die Casting Services

Why Aluminum Surface Finishing Matters

Aluminum is a lightweight, corrosion-resistant metal—but its surface properties can vary greatly depending on the casting process and the environment it’s used in. Bare cast aluminum, especially from die casting, often has micro-porosity, oxide layers, or surface impurities that can affect paint adhesion or long-term durability.

Proper aluminum finishes address these challenges by:

- Enhancing corrosion resistance (especially for marine and outdoor use)

- Improving wear and abrasion resistance for moving parts

- Providing electrical insulation or conductivity as required

- Creating visually appealing textures and colors

- Boosting part longevity under thermal cycling or mechanical stress

Whether you’re developing components for automotive, aerospace, electronics, or telecom, understanding the options for aluminum finishing is essential to achieving performance, aesthetic, and cost targets.

Understanding Aluminum Surface Properties Before Finishing

Before applying any finish, it’s crucial to understand the inherent characteristics of a cast aluminum surface.

- Natural Oxidation: Aluminum is a highly reactive metal that instantly forms a thin, tough, and transparent layer of aluminum oxide upon exposure to air. This layer provides a degree of natural corrosion protection. However, for most applications, this native layer is insufficient and needs to be enhanced or replaced by a more robust finish.

- Casting Process and Surface Quality: The casting method directly influences the part’s surface quality. High-Pressure Die Casting (HPDC) typically produces a smooth, non-porous surface skin, while Sand Casting results in a much rougher texture with a higher likelihood of surface porosity.

- Key Finishing Challenges: Casting processes can introduce surface defects that must be addressed before finishing. Common challenges include porosity (trapped gas bubbles), cold shuts (lines where two metal fronts failed to fuse properly), and flow lines. These imperfections can cause adhesion failure, blistering, and an uneven appearance if not properly treated.

7 Types of Aluminum Finishes for Cast Components

Here are seven of the most effective and widely used surface treatments for aluminum castings.

1. Powder Coating

Powder coating is a dry finishing process where a finely ground powder of pigment and resin is electrostatically applied to the surface and then cured under heat. This melts the powder into a smooth, continuous film.

- Principles and Applications: It creates a durable, uniform, and attractive finish that is far more resistant to chipping, scratching, and fading than standard wet paint. It’s ideal for electronic housings, automotive components, outdoor furniture, and architectural parts.

- Key Benefits: Offers an extensive color range, excellent corrosion protection, and is environmentally friendly with minimal VOCs.

Alloy Compatibility: Works exceptionally well with common casting alloys like A380, A356, and ADC12. However, proper pretreatment is essential to degas the part and prevent surface porosity from causing blisters during curing.

2. Anodizing

Anodizing is an electrochemical process that enhances the natural oxide layer, making it thicker, harder, and more durable. The part is submerged in an electrolytic acid bath, and an electric current is passed through it.

- Structure and Thickness: The resulting anodic layer is integral to the aluminum itself, not just a coating. Its thickness can be precisely controlled, typically from 5 to 25 µm.

- Suitability for Die-Cast Aluminum: Anodizing high-silicon casting alloys (like A380) can be challenging, often resulting in a non-uniform, grayish appearance. It is better suited for low-silicon alloys and is most effective on machined surfaces of a cast part.

- Applications: Widely used in aerospace, optical components, and high-end consumer electronics where hardness, wear resistance, and dielectric properties are required.

3. Painting & Wet Spray Coating

Liquid painting remains a popular and cost-effective method for achieving a decorative finish on cast aluminum parts. It involves spraying liquid paint onto a prepared surface.

- Pros and Cons: Wet spray offers a vast color selection and is excellent for parts that cannot be heated, unlike powder coating. However, it is generally less durable and more susceptible to chipping and wear. Adhesion is a primary concern.

- Role of Priming: A crucial step for ensuring durability is the application of a high-quality primer. A chromate or non-chromate conversion coating is often used as a base to dramatically improve paint adhesion and corrosion resistance.

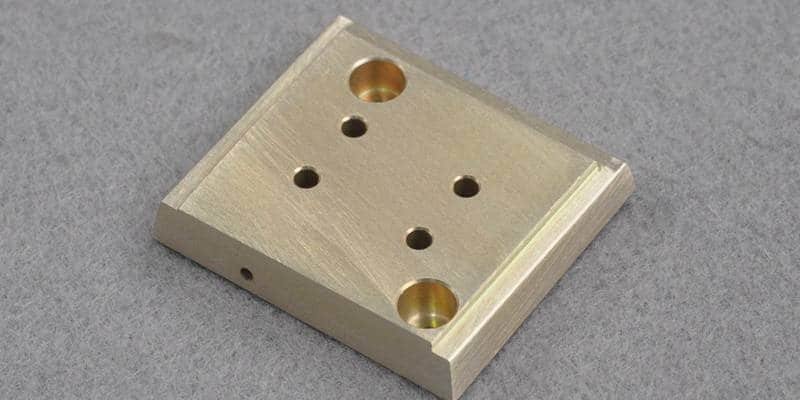

4. Electroplating (e.g., Nickel, Chrome)

Electroplating involves depositing a thin layer of another metal onto the aluminum surface. This is done for decorative appeal, enhanced corrosion resistance, improved hardness, or to add solderability.

- Critical Pretreatment: Aluminum cannot be directly electroplated. The surface must first undergo a complex pretreatment process, most commonly involving a zincate layer. This is followed by a strike of copper or electroless nickel before the final plated layer (e.g., bright chrome, nickel, tin, or silver) is applied.

- Common Uses: Frequently seen in automotive trim for its bright, reflective finish, as well as on decorative hardware, plumbing fixtures, and some electronic components.

5. Bead Blasting / Sandblasting

Also known as abrasive blasting, this is a mechanical surface treatment used to clean, deburr, and texturize a part. It propels a stream of abrasive media against the surface under high pressure.

- Purpose: It is rarely a final finish but is a critical pre-treatment step. It removes casting skin and minor imperfections, creating a uniform matte texture that is ideal for improving the adhesion of subsequent finishes like powder coating or painting.

Effects of Different Media: The final texture depends on the media used. Glass beads produce a smooth, satin finish, while harder media like aluminum oxide create a rougher, more etched profile.

6. Brushed / Mechanical Polishing

Mechanical finishing involves using abrasives to create a specific surface texture. A brushed finish is created by scouring the surface with a fine abrasive to create a unidirectional satin look. Polishing uses progressively finer abrasives to create a smooth, highly reflective mirror finish.

- Applications: Popular in consumer electronics (laptop casings), architectural trim, and high-end lighting fixtures where a distinct, high-end look is desired.

- Limitations: This method is best suited for parts with large, flat, or simple curved surfaces. It is difficult and labor-intensive to apply uniformly on components with complex geometry, deep pockets, or sharp internal corners.

7. Chemical Conversion Coating (Alodine / Chromate)

A chemical conversion coating is a non-electrolytic process where the aluminum part is dipped in or sprayed with a chemical solution (traditionally containing hexavalent chromium). This forms a thin, protective film on the surface.

- Conductivity and Corrosion Protection: Unlike anodizing, this coating is electrically conductive, making it suitable for electronic housings where EMI shielding is needed. It provides excellent corrosion resistance and is an exceptional primer for paint.

Aerospace and Telecom Applications: It is a standard finish in the aerospace, military, and telecommunications industries due to its reliability and protective properties. RoHS-compliant, chromium-free alternatives are now widely available.

Comparison Table: Aluminum Finishes by Functionality

| Finish Type | Corrosion Resistance | Wear Resistance | Electrical Conductivity | Visual Appeal | Cost |

|---|---|---|---|---|---|

| Anodizing (Type II) | ★★★★☆ | ★★★☆☆ | ★☆☆☆☆ | ★★★★☆ | Medium |

| Hard Anodizing (Type III) | ★★★★★ | ★★★★★ | ★☆☆☆☆ | ★★★☆☆ | Medium-High |

| Chromate Conversion (Alodine) | ★★★★☆ | ★★☆☆☆ | ★★★★☆ | ★★☆☆☆ | Low |

| Powder Coating | ★★★★★ | ★★★★☆ | ☆☆☆☆☆ | ★★★★★ | Medium |

| Liquid Painting | ★★★☆☆ | ★★☆☆☆ | ☆☆☆☆☆ | ★★★★★ | Low-Medium |

| Electroless Nickel Plating | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★★☆ | High |

Choosing the Right Aluminum Finish for Your Application

Selecting the ideal surface finish isn’t just about appearance—it directly influences product longevity, functional performance, and end-user satisfaction. Below are key considerations to guide engineers and procurement managers in making an informed choice.

1. Corrosion Environment

- Outdoor or Marine Exposure: Choose anodizing or fluoropolymer powder coating for maximum corrosion resistance.

- Industrial Use with Mild Exposure: Chromate conversion coatings or e-coating offer a cost-effective protective barrier.

2. Aesthetic Requirements

- Consumer electronics or decorative parts often benefit from anodizing with dyed color options, brushed aluminum, or mirror polishing for a premium feel.

- Automotive and architectural parts may require powder coating with color-matching, texture control, and gloss level customization.

3. Functional Requirements

- Wear and Abrasion Resistance: Consider hard anodizing or ceramic coatings for enhanced durability.

- Electrical Conductivity: Use chemical conversion coatings (like Alodine) to maintain conductivity while offering protection.

4. Thermal Performance

- Heat Sinks or Lighting Housings: Use finishes that enhance emissivity, such as black anodizing or thermally conductive powder coatings.

5. Post-Machining Compatibility

For parts requiring tight tolerance machining after casting, finishes like clear anodizing or passivation are less likely to alter dimensions.

Real-World Applications of Aluminum Finishes

| Industry | Part | Typical Finish | Reason |

|---|---|---|---|

| Automotive | Suspension arms, housings | Powder Coating, E-coat | Corrosion and abrasion resistance |

| Electronics | Enclosures, heat sinks | Anodizing, Chromate | Heat dissipation and EMI protection |

| Aerospace | Structural castings | Hard Anodizing, Alodine | Strength, fatigue resistance, and conductivity |

| Marine | Engine covers, brackets | Anodizing (Type II/III) | Saltwater corrosion resistance |

| Architecture | Frames, decorative panels | Fluoropolymer powder coating | UV stability, weathering resistance |

Common Defects and Quality Control in Aluminum Finishing

Achieving a high-quality finish depends on controlling both the casting and finishing processes.

- Common Issues:

- Exposed Porosity: Gas porosity just below the surface can be exposed during blasting, creating pinholes. In heat-cured finishes like powder coating, this can lead to outgassing and blistering.

- Adhesion Failure: The number one cause is improper surface preparation. Oil, grease, or an unstable oxide layer must be completely removed.

- Discoloration: Can occur during anodizing high-silicon alloys or from inconsistent heat treatment.

- How to Reduce Defects: Work with your casting supplier to minimize porosity in critical areas. Ensure a robust, multi-stage pretreatment process (cleaning, etching, deoxidizing) is used before any final finish is applied.

- Matching Surface Roughness (Ra): The surface roughness must be appropriate for the finish. A highly polished surface is unsuitable for painting, which needs a slightly roughened profile for good mechanical adhesion. Specify an acceptable Ra range for critical surfaces.

Conclusion: Finishing Strong with Aluminum

Whether you’re engineering precision components for aerospace or sourcing architectural trims, selecting the right aluminum finish is vital for ensuring performance, aesthetics, durability, and compliance.

From corrosion resistance to thermal regulation, from brand aesthetics to machining compatibility, aluminum finishing technologies offer solutions for virtually every industrial challenge. But with so many choices—anodizing, powder coating, e-coating, conversion coatings—success lies in understanding the interplay between alloy, process, finish, and application.

At CastMold, we specialize in helping our clients navigate these complex decisions with expert guidance, flexible processing capabilities, and quality-first execution. Whether you need help choosing the right alloy and finish combination, managing tight tolerance coatings, or ensuring cost-effective scalability, we’re here to support your production goals with precision from design to delivery.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.