When Apple unveiled the iPhone 17 Pro, one particular change in its technical specifications sparked widespread industry discussion: the frame material shifted from the celebrated titanium of the previous two generations back to a more traditional aluminum alloy. On the surface, this might have seemed like a “downgrade.” However, as experts in the precision manufacturing field, we at CastMold assert that this was not a simple cost-cutting measure, but a systemic redesign aimed at unlocking sustained high performance for the A19 Pro chip and on-device “Apple Intelligence.”

This strategic decision was built on the synergy of three key pillars: a material upgrade to 7000 series aluminum, a structural innovation to an integrated unibody design, and a manufacturing pivot towards near-net-shape processes like hot forging and high-pressure die casting (HPDC). Together, they served a singular purpose: to achieve superior thermal efficiency, a lighter feel in the hand, and greater scalability in mass production.

- The Bottleneck: Titanium's Thermal "Ceiling"

- The Technical Return: The Debut of "Aerospace-Grade" 7000 Series Aluminum

- The Manufacturing Pivot: A Leap in Speed and Efficiency

- System Synergy: Turning the Enclosure into an Active Thermal System

- Economic and Sustainability Implications

- Conclusion: A Masterclass in Holistic Product Engineering

- FAQs

- Aluminum Die Casting Services

The Bottleneck: Titanium’s Thermal “Ceiling”

The “titanium frame + glass back” sandwich construction of the iPhone 15 and 16 Pro, while praised for its premium feel and strength, exposed a critical engineering bottleneck: heat dissipation.

- The Thermal Conductivity Flaw: Titanium alloy (typically Ti-6Al-4V) has a thermal conductivity of only about 6.6–22 W/m·K. This is nearly an order of magnitude lower than 7000 series aluminum (approx. 130 W/m·K). This meant that when the A-series chip was under heavy load, the generated heat could not be conducted away quickly and evenly through the frame. This led to localized heat buildup and, ultimately, “thermal throttling” (a reduction in processor frequency), which compromised sustained peak performance.

- The Sustained Thermal Load of AI: The A19 Pro chip in the iPhone 17 Pro was engineered with a core mission: to efficiently run on-device Large Language Models (LLMs), generative imaging, and more complex 4K video streams and game rendering. These “Apple Intelligence” applications all share a common trait of creating prolonged, high-load conditions, placing unprecedented and rigid demands on the underlying thermal architecture.

- The Manufacturing Challenges of Titanium: The difficulty and cost of machining titanium have always been high. The CNC cutting process is slow, causes rapid tool wear, and results in a relatively lower yield rate. Coupled with high raw material costs, these factors limited its economic viability and supply chain flexibility at the immense scale of iPhone production.

The Technical Return: The Debut of “Aerospace-Grade” 7000 Series Aluminum

Apple’s return was not to just any aluminum, but to the 7000 series, often referred to as “aerospace-grade aluminum.”

Alloy System and Heat Treatment

Composed mainly of zinc, magnesium, and copper, 7000 series aluminum, when subjected to a T6 temper (solution heat-treated and then fully artificially aged), achieves an extremely high level of strength and specific strength. This allows it to meet the rigorous structural demands of a smartphone while providing excellent anodizing properties, laying the foundation for rich colors and a premium finish.

A Quantitative Material Comparison

Placing aluminum alongside titanium and stainless steel clearly illustrates the trade-offs:

| Performance Metric | 7000 Series Aluminum | Titanium (Ti-6Al-4V) | Stainless Steel (316L) |

| Thermal Conductivity (W/m·K) | ~130 (Excellent) | ~6.7 (Poor) | ~15 (Fair) |

| Density (g/cm³) | ~2.81 (Lightest) | ~4.43 (Mid-weight) | ~8.0 (Heaviest) |

| Hardness / Scratch Resistance | Good | Excellent | Excellent |

| Manufacturing Cost & Efficiency | Low / High | High / Low | Medium / Medium |

The data in this table illuminates the core engineering trade-off at the heart of the iPhone 17 Pro’s design.

- Thermal Conductivity: This is the most critical factor. 7075-T6 Aluminum’s thermal conductivity of ~130 W/m-K is approximately 19 times greater than that of Grade 5 Titanium (~6.7 W/m-K) and nearly 9 times greater than that of 316L Stainless Steel (~15 W/m-K). This enormous advantage in heat dissipation is the primary technical justification for the material change, as it allows the entire unibody chassis to function as an effective heat sink for the A19 Pro chip.

- Density and Weight: Aluminum is by far the lightest of the three materials. At 2.81 g/cm3, it is about 36% lighter than titanium and 65% lighter than stainless steel. For a handheld device, this translates into a significant improvement in ergonomics and user comfort, directly addressing a common complaint about the heft of previous Pro models.

- Strength and Hardness: This is where the trade-off is made. In terms of absolute strength and surface hardness, both titanium and stainless steel are superior to aluminum. Grade 5 Titanium is significantly harder (334 HB vs. 150 HB) and therefore much more resistant to scratches and scuffs. While the 7000-series alloy is exceptionally strong

The Manufacturing Pivot: A Leap in Speed and Efficiency

A key driver for the switch was the ability to leverage far more efficient manufacturing techniques. Apple moved away from the slow, subtractive process of CNC machining titanium and embraced the speed of near-net-shape aluminum forming.

A Closer Look at the Manufacturing Processes

The shift to aluminum unlocked two powerful, high-speed industrial processes:

- High-Pressure Die Casting (HPDC): This is a process where molten aluminum alloy is injected into a hardened steel mold (a “die”) under immense pressure and at high speed. The metal solidifies in a matter of seconds, allowing a complex part, like the iPhone’s unibody chassis, to be formed with incredible precision. The entire manufacturing cycle is measured in seconds, not the many minutes or even hours required for CNC machining a part from a solid block. At CastMold, this is a core competency we use to deliver millions of parts with consistent quality at unparalleled speeds.

- Hot Forging: In this process, a solid billet of aluminum is heated until it becomes malleable and is then pressed between two dies with tremendous force. This action doesn’t just shape the metal; it refines its internal grain structure, eliminating porosity and aligning the grains to produce a final part with exceptional strength and fatigue resistance.

Both HPDC and hot forging are “near-net-shape” methods, meaning the initial part is very close to its final geometry. This drastically reduces material waste and the subsequent time needed for final CNC machining, directly contributing to faster production cycles and the ability to ramp up to the massive volumes Apple requires.

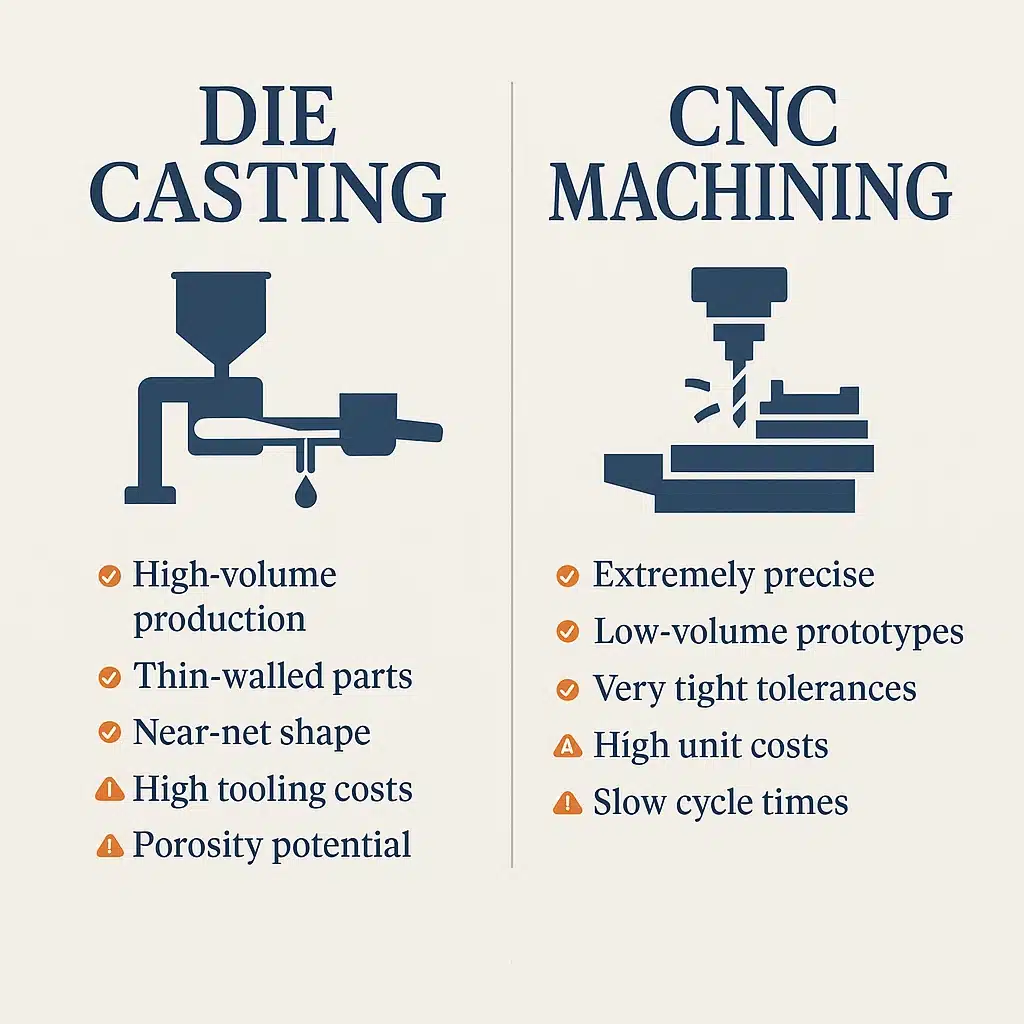

Comparative Analysis: Die-Casting vs. CNC Machining

The strategic decision to move to a net-shape forming process like die-casting or forging becomes even clearer when compared directly with Apple’s traditional method for unibody construction: full CNC machining.

| Metric | High-Pressure Die-Casting (HPDC) | Multi-axis CNC Machining | Hot Forging |

| Core Principle | Additive (Molten metal injected into mold) | Subtractive (Material removed from solid block) | Deformative (Solid metal pressed into shape) |

| Volume Suitability | Very High (10,000s to Millions) | Low to Medium (1s to 1,000s) | High (1,000s to Millions) |

| Cycle Time per Unit | Very Low (Seconds to minutes) | High (Minutes to hours) | Low (Seconds to minutes) |

| Upfront Tooling Cost | Very High | Low (No custom mold required) | Very High |

| Material Waste | Very Low | Very High (“Buy-to-fly” ratio is poor) | Low to Moderate |

| Geometric Complexity | High (Complex internal features possible) | Moderate (Limited by tool access) | Moderate (Less complex than casting) |

| Typical Precision | Good to Excellent | Excellent to Exceptional | Good |

System Synergy: Turning the Enclosure into an Active Thermal System

The genius of the iPhone 17 Pro’s design lies in the fact that the enclosure was no longer treated as an isolated structural component, but as an integral part of the thermal management system.

- The Unibody as a Giant Heatsink: The new unibody aluminum chassis, likely integrated with a larger Vapor Chamber (VC) via laser welding, created a highly efficient thermal pathway. Heat from the A19 Pro was rapidly spread by the VC across the entire aluminum body, which then used its vast surface area to dissipate the heat into the environment. This is a system-level advantage that a frame with poor thermal conductivity, like titanium, could not match.

- Process-Driven Design: The ability of die casting and forging to create complex 3D shapes, such as seamlessly integrating the “camera plateau” into the rear shell, was a key enabler. This not only improved structural integrity and water resistance but also freed up precious internal volume to accommodate a larger battery and the new trio of 48MP camera modules.

Economic and Sustainability Implications

Beyond performance and ergonomics, the move to aluminum brought significant advantages in cost and environmental responsibility.

A Greener Footprint with 100% Recyclability

Aluminum is one of the most recycled and recyclable materials on the planet. An aluminum iPhone chassis can be made from 100% recycled material, and the material itself is infinitely recyclable without losing its properties. Recycling aluminum requires up to 95% less energy than producing primary aluminum from bauxite ore. This aligns perfectly with Apple’s aggressive environmental goals to achieve carbon neutrality across its entire product lifecycle by 2030. By choosing aluminum, Apple made a powerful statement about its commitment to sustainability.

Conclusion: A Masterclass in Holistic Product Engineering

The iPhone 17 Pro’s return to an aluminum unibody was a deliberate and visionary engineering decision. It was a masterclass in holistic design where the choice of material was not made in isolation. Instead, Apple orchestrated a symphony of material science (high-conductivity, lightweight aluminum), advanced manufacturing (HPDC/forging), and system architecture (integrated thermal design) to solve the defining challenges of the AI era.

The result was a device that is not only more powerful but also lighter, cooler, more sustainable, and manufacturable at scale—a clear win for the end-user.

FAQs

Your Ideal Partner in Advanced Aluminum Manufacturing

Does your product require a high-performance, lightweight, and thermally efficient metal enclosure? The design philosophy demonstrated in the iPhone 17 Pro—deeply integrating material, process, and structure—is at the core of what we do at CastMold. We specialize in high-pressure die casting, precision CNC machining, and high-quality surface finishing for aluminum and zinc alloys.

If you are looking for a reliable die casting partner for your project, contact CastMold today. We will provide a free quote and a Design for Manufacturability (DFM) review to ensure your product achieves peak performance and cost-effectiveness.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.