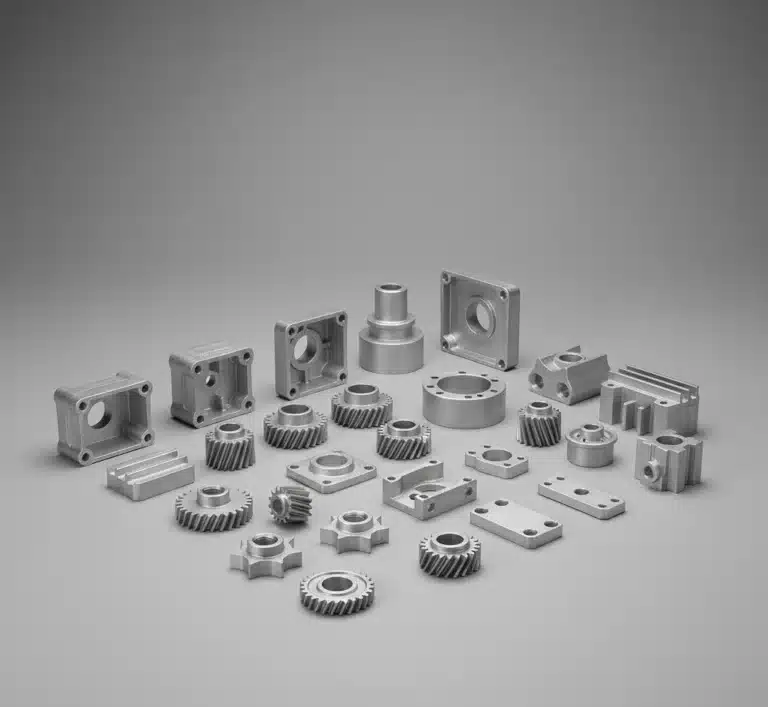

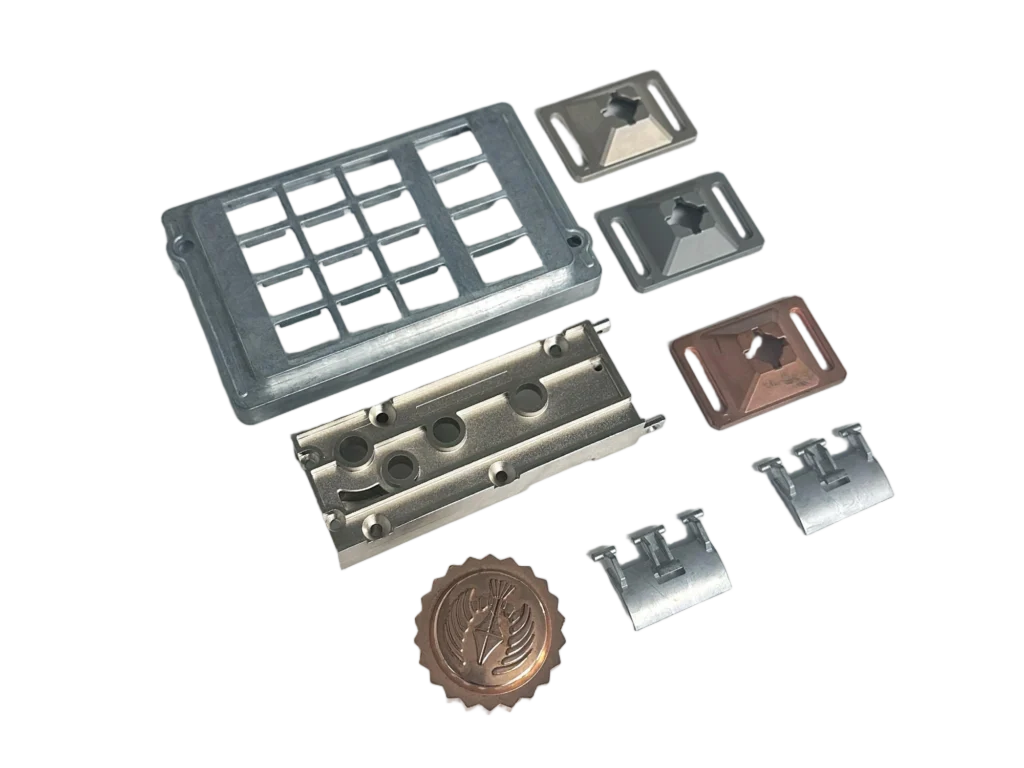

When precision, intricate detail, and a superior surface finish are non-negotiable, engineers and designers turn to Zamak alloys. As a family of zinc-based alloys supercharged with aluminum, magnesium, and copper, Zamak is the cornerstone of high-pressure zinc die casting. Its exceptional fluidity allows for incredibly thin walls and crisp features, while its low melting point enables fast cycle times and extremely long die life. This unique combination makes it ideal for everything from decorative plated hardware to precision mechanisms and pressure-tight housings.

- What Is Zamak / Zamak Alloy?

- History of Zamak

- The Zinc Alloy Landscape

- Zamak Grades & Quick Comparison

- Zinc vs. Aluminum vs. Magnesium: A Comparative Overview

- Why Zinc Die Casting Is the Ideal Process for Zamak

- The Zinc Die Casting Process

- DFM (Design for Manufacturability) for Zamak Parts

- Zinc Die Casting Surface Finishing

- Quality & Validation

- Cost & Sustainability

- Applications & Mini Case Studies

- Zamak vs. Aluminum Die Casting: The Deciding Factors

- FAQs

- Work With CastMold on Your Next Zamak Project

What Is Zamak / Zamak Alloy?

At its core, Zamak is an acronym for its constituent metals (from their German names): Zink, Aluminium, Magnesium, and Kupfer (Copper). This family of alloys is specifically engineered for the hot-chamber die casting process, offering a blend of properties that are difficult to match with other materials.

The role of each alloying element is critical:

- Aluminum (Al): Typically around 4%, aluminum is the primary strengthener, significantly boosting the alloy’s hardness, tensile strength, and overall castability.

- Magnesium (Mg): Added in very small amounts (0.03-0.06%), magnesium refines the grain structure, improves stability, and plays a crucial role in preventing intergranular corrosion.

- Copper (Cu): When included, copper increases strength, hardness, and wear resistance, though it can slightly reduce ductility.

Choose Zamak when your project demands:

- Complex geometries and small, intricate parts.

- Very thin walls (under 1mm in some cases).

- A premium, cosmetic finish suitable for electroplating.

- High production volumes with exceptional part-to-part repeatability.

- Fast manufacturing cycles and lower tooling amortization costs.

History of Zamak

The origins of Zamak date back to the early 20th century. Early zinc alloys were often brittle and suffered from dimensional instability over time. The key breakthrough came with the development of high-purity (99.99%) zinc, which, when combined with precise alloying control, dramatically reduced impurities that caused porosity, creep, and dimensional drift.

This led to the evolution of the modern Zamak family, starting with the versatile Zamak 3 as the general-purpose standard. From there, other grades were developed to meet specific engineering needs: Zamak 5 added copper for higher strength, Zamak 2 was formulated for superior creep resistance in long-term load applications, and Zamak 7 further reduced impurities for the best fluidity and thin-wall casting performance.

The Zinc Alloy Landscape

While the Zamak family is the most common, it’s part of a broader landscape of zinc alloys used in die casting.

- Zamak Family: Zamak 2, 3, 5, and 7 are the workhorses of hot-chamber die casting, each offering a distinct balance of properties.

- ZA Series: Alloys like ZA-8, ZA-12, and ZA-27 contain higher aluminum content. This gives them increased strength and wear resistance, but their higher melting points often require modified process control or the use of cold-chamber machines.

- Special Variants: For specific applications, you can find lead-free alloys for RoHS/REACH compliance or proprietary formulations developed for enhanced corrosion resistance or strength.

Zamak Grades & Quick Comparison

Choosing the right grade is crucial for project success. Here’s a quick-glance comparison of the most common Zamak alloys we work with at CastMold.

| Grade | Key Composition Note | Strength/Hardness (Relative) | Ductility (Relative) | Dimensional Stability | Plating/Finishing | Typical Uses |

| Zamak 3 | The “default” grade, base alloy | Good | Excellent | Excellent | Excellent | General hardware, toys, automotive trim, appliance parts |

| Zamak 5 | ~1% Copper added | Excellent | Good | Very Good | Excellent | Structural components, gears, parts needing higher wear |

| Zamak 2 | ~3% Copper, higher hardness | Highest | Fair | Good | Good | Bushings, bearings, gears, high-load/wear applications |

| Zamak 7 | Lower Mg, tighter impurity control | Good | Excellent | Excellent | Superior | Ultra-thin walls, fine details, complex cosmetic parts |

Zamak 3

This is the most widely used zinc alloy in North America due to its excellent combination of castability, dimensional stability, and finishing characteristics. It provides the perfect baseline for a wide range of applications and is the first choice unless specific properties like higher strength are required.

Zamak 5

The addition of about 1% copper makes Zamak 5 stronger and harder than Zamak 3. This is the most popular grade in Europe. It’s an excellent choice for structural applications or parts that will experience moderate, sustained loads.

Zamak 2

Also known as a gravity-casting alloy, Zamak 2 has the highest strength and hardness in the family. Its primary advantage is its superior creep performance, making it the best option for parts under constant stress or load over long periods, such as gears and bushings.

Zamak 7

With lower magnesium content and tighter impurity limits, Zamak 7 boasts the best casting fluidity. This allows for filling extremely thin-walled sections and replicating fine, intricate details with high fidelity, making it ideal for high-value cosmetic components.

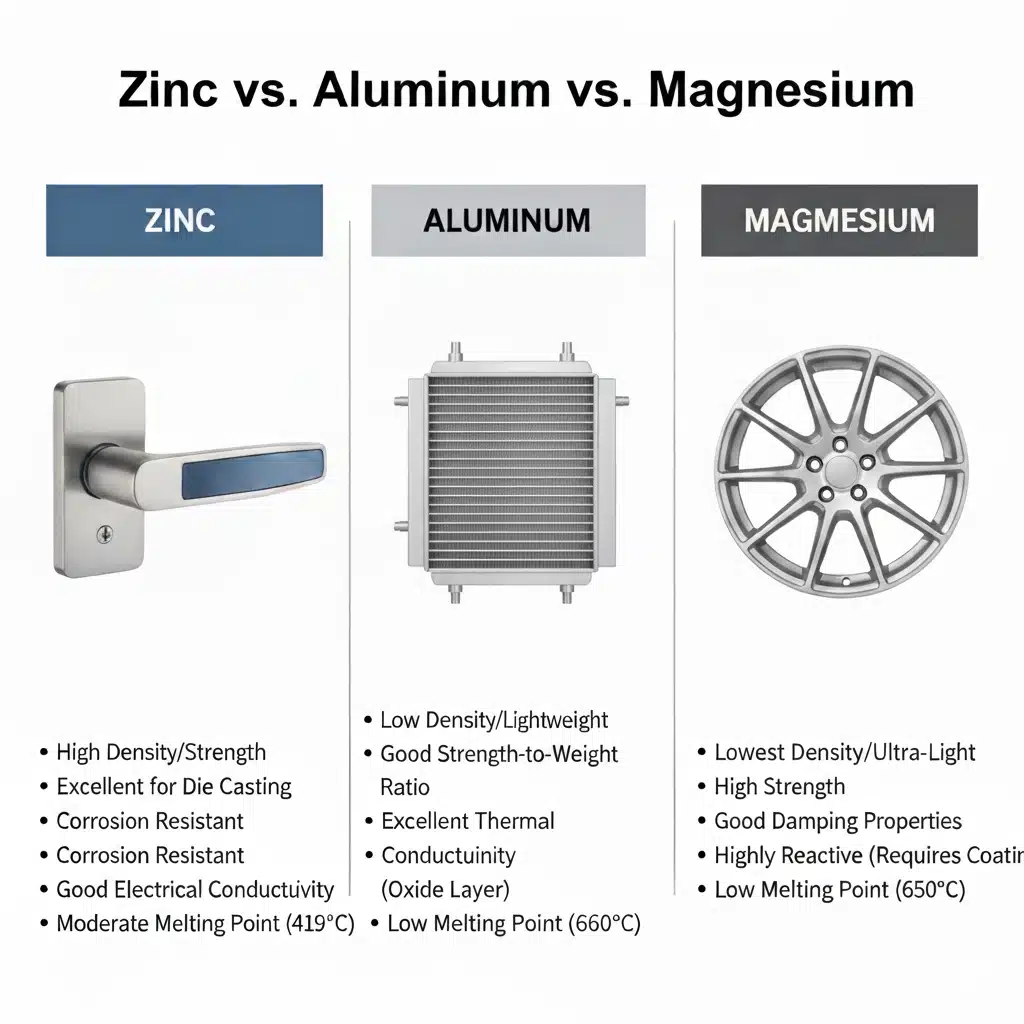

Zinc vs. Aluminum vs. Magnesium: A Comparative Overview

Understanding where Zamak fits requires comparing it to other common die casting materials.

| Property / Factor | Zinc (Zamak) | Aluminum (e.g., A380) | Magnesium (e.g., AZ91D) |

| Density | High (heavier feel) | Low (lightweight) | Lowest (ultra-lightweight) |

| Melting Point | Low (~385°C) | Medium (~565°C) | Medium (~595°C) |

| Fluidity / Thin Wall | Excellent (can fill <0.5mm) | Good (typically >1.2mm) | Very Good |

| Dimensional Accuracy | Excellent (low shrink, high precision) | Good | Good |

| Strength / Specific Strength | Good Strength / Low Specific Strength | Excellent Strength / High Specific Strength | Good Strength / Highest Specific Strength |

| Elastic Modulus | Medium | High | Low |

| Corrosion / Finishing | Excellent for plating; good corrosion resistance | Good resistance; can be anodized, painted | Requires careful surface treatment to prevent corrosion |

| Thermal Conductivity | Good | Excellent | Good |

| Die Life / Cycle Time | Very Long Die Life / Very Fast Cycles | Medium Die Life / Medium Cycles | Shorter Die Life / Fast Cycles |

| Unit Cost at Volume | Competitive; fast cycles offset material cost | Generally Lower | Higher |

Why Zinc Die Casting Is the Ideal Process for Zamak

The properties of Zamak alloys are perfectly matched to the advantages of the high-pressure die casting process.

- Superior Fill & Thin Walls: Zamak’s exceptional fluidity and low melting point allow it to fill complex cavities and create features with wall thicknesses that are impossible for many other alloys.

- Cosmetic Excellence: The process yields a smooth, as-cast surface that is an ideal substrate for a wide range of finishes, especially decorative electroplating.

- High Throughput & Cost-Effectiveness: The low melting temperature requires less energy and is far less aggressive on tooling. This translates to extremely long die life (often over 1 million shots) and very short cycle times, creating strong economic advantages at scale.

- Net-Shape Precision: Low shrinkage and high dimensional stability mean parts come out of the mold with tight tolerances, minimizing or eliminating the need for secondary machining operations.

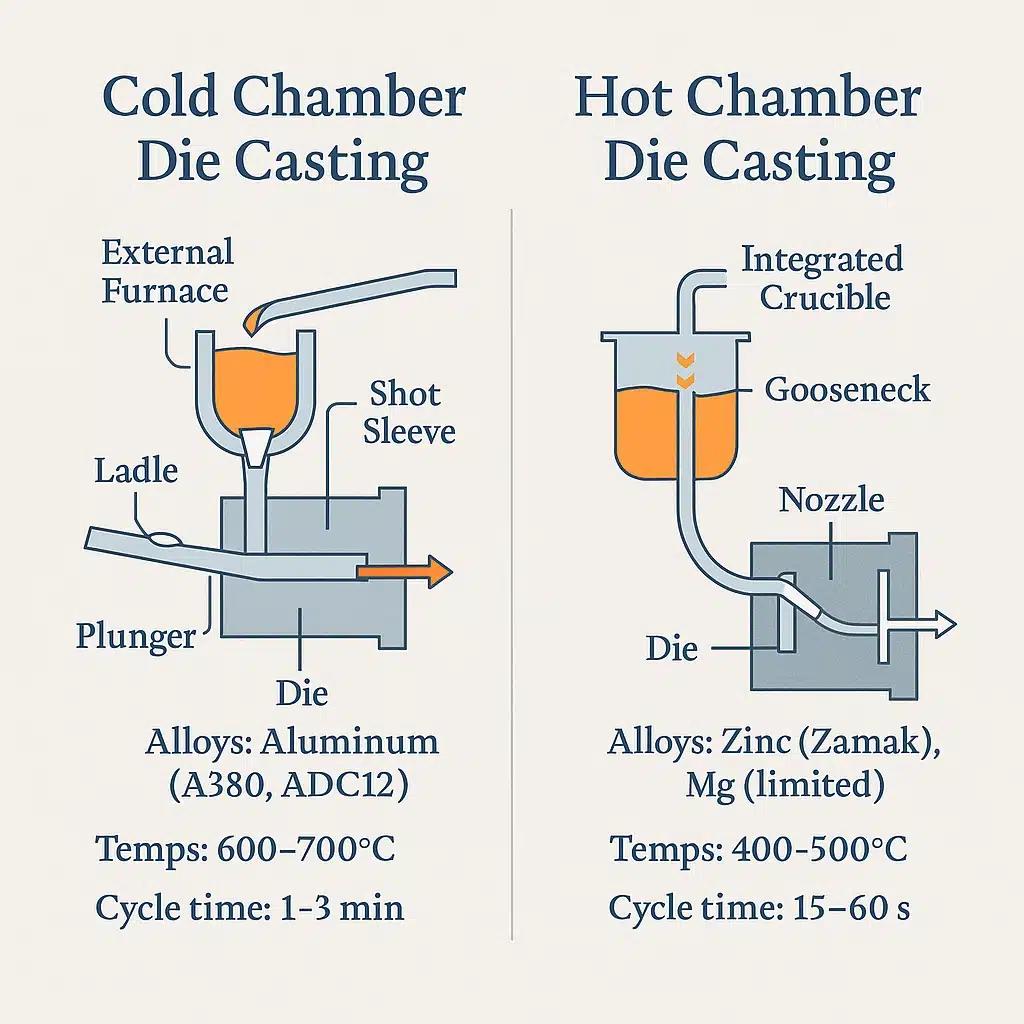

The Zinc Die Casting Process

Hot-Chamber (The Primary Route for Zamak)

This is the dominant process for Zamak 2, 3, 5, and 7. The injection mechanism, a “gooseneck,” is submerged in the molten metal pot. This allows for a very fast and direct injection of metal into the die. The process is thermally efficient, highly repeatable, and enables rapid cycle times.

Cold-Chamber (For Select Cases)

This method is used for alloys with higher melting points, like the ZA series, or in special circumstances. A precise amount of molten metal is ladled into a “cold” shot sleeve before being injected by a plunger. The process is slower than hot-chamber.

Critical Process Parameters

Achieving consistent, high-quality parts requires precise control over dozens of variables. At CastMold, we focus on:

- Die Design: Proper gating, overflow design, and venting are crucial to ensure complete fill and prevent trapped gas porosity.

- Thermal Management: Maintaining a stable die temperature is key to controlling part dimensions and surface finish.

- Process Control: We monitor shot speed, pressure curves, and displacement in real-time to ensure every part is made under identical conditions.

- Mass Production Control: We use Statistical Process Control (SPC), first-article inspection, and patrol checks alongside a rigorous die maintenance schedule. This allows us to identify and correct potential issues like cold shuts, soldering, or porosity before they impact production.

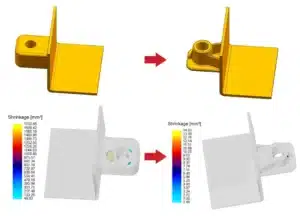

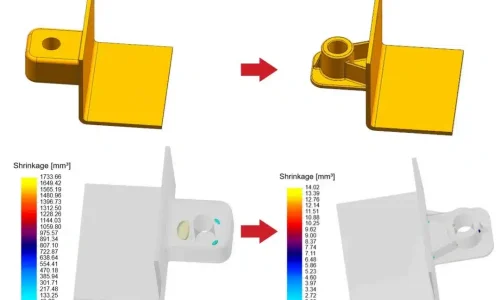

DFM (Design for Manufacturability) for Zamak Parts

Partnering with us early in the design phase allows us to optimize your part for manufacturing, saving you time and money.

DFM Checklist for Zamak Parts

- Uniform Wall Thickness: Aim for consistency to prevent shrink porosity and stress.

- Generous Fillets: Use smooth transitions at corners and intersections to improve metal flow and strength.

- Incorporate Draft: Add a slight taper to all walls parallel to the die opening direction for easy ejection. 1-2 degrees is typical.

- Ribs for Strength: Use ribs (0.5-0.7x the adjoining wall thickness) instead of thick sections to add stiffness.

- Design Sensible Holes/Bosses: Avoid overly deep holes and ensure bosses have proper fillets and draft.

- Mind the Parting Line: Place it strategically to hide it on non-cosmetic surfaces.

- Plan for Ejector Pins: Locate ejector pin marks on non-visible or non-critical surfaces.

- Consider Threads: Can threads be cast-in, or are they better formed or machined post-cast?

- Overmolding Inserts: Account for thermal expansion if metal inserts will be cast-in-place.

- Define Critical Tolerances: Clearly identify which features require the tightest control and which can be more flexible.

Walls & Ribs

A baseline wall thickness of 1.0mm to 2.5mm is a good starting point. Ribs should be used to add stiffness without creating heavy, slow-cooling sections.

Draft

Draft is essential. For cosmetic surfaces that will be polished or plated, the location of the parting line and the quality of the draft are critical to achieving a flawless finish.

Holes, Bosses, Threads & Inserts

Zamak is excellent for forming threads using self-tapping screws. We can also accommodate press-fit or heat-staked inserts. If metal inserts are overmolded, careful thermal management is required to prevent part cracking.

Tolerances & Secondary Operations

While Zamak offers excellent as-cast precision, critical datums, bores, or sealing surfaces often require secondary CNC machining to achieve the highest level of tolerance.

Zinc Die Casting Surface Finishing

Zamak’s smooth surface is a perfect canvas for a variety of finishes.

- Electroplating: This is where Zamak truly shines. Common stacks like Copper-Nickel-Chrome provide a brilliant, durable decorative finish. Proper substrate cleaning and activation are key to preventing blistering and ensuring adhesion.

- Conversion Coatings: Trivalent chromates can be used to improve corrosion resistance or serve as an excellent primer for paint and powder coating.

- Powder Coating & Painting: A durable and decorative option. Success depends on a robust pretreatment process (degreasing, conversion coating) to ensure excellent adhesion.

Mechanical Finishes: Processes like vibratory finishing (rumbling), polishing, and blasting can be used to achieve specific textures or prepare the surface for subsequent coatings.

Quality & Validation

We ensure part quality through a multi-stage validation process:

- NDT: X-ray or CT scanning to detect internal porosity.

- Leak/Pressure Testing: For housings and fluid-handling components, we perform air-over-water pressure tests to guarantee seal integrity.

- Metrology: CMM (Coordinate Measuring Machine) inspections and custom gauges verify that all critical dimensions, datums, and geometric tolerances are met.

- Process Capability: We use CpK and PpK analysis to ensure our process is stable and capable of meeting your specifications consistently over high-volume production runs.

Cost & Sustainability

- Tool Life: A Zamak die can often last for over a million cycles, far exceeding the typical life of a die for aluminum (100k-150k cycles). This significantly reduces the amortized cost of tooling per part.

- Material & Recycling: Zinc alloys are highly recyclable. At CastMold, we efficiently reclaim and reuse internal scrap, maintaining strict melt quality control to ensure material integrity.

- Compliance: We offer RoHS and REACH-compliant alloys, including low-lead and lead-free options, to meet global regulatory requirements.

Applications & Mini Case Studies

- Application: High-End Door Hardware

- Objective: Create a door handle with a premium, heavy feel and a flawless chrome-plated finish.

- Solution: We used Zamak 5 for its strength and superior plating characteristics. Our DFM analysis ensured a parting line that was invisible after polishing. The hot-chamber process delivered a smooth surface that required minimal preparation for plating, resulting in a cost-effective, high-quality cosmetic part.

- Application: Consumer Electronics Enclosure

- Objective: Design a thin-walled, rigid housing for a handheld device with internal snap features and EMI shielding.

- Solution: Zamak 7 was selected for its exceptional fluidity to fill the <1.0mm wall sections. The as-cast precision created functional snap-fit features directly out of the tool. A conductive conversion coating was applied internally for EMI shielding, delivering a robust, net-shape part with integrated functionality.

- Application: Automotive Sensor Housing

- Objective: Produce a small, pressure-tight housing that required high dimensional accuracy for sensor alignment.

- Solution: Zamak 3 provided the necessary stability. The part was designed with an O-ring groove for sealing. Post-cast, each part underwent a CNC operation to machine a critical mounting face and was then subjected to a 100% pressure decay leak test to guarantee performance.

Zamak vs. Aluminum Die Casting: The Deciding Factors

The choice often comes down to a few key trade-offs:

- Choose Zamak for thin walls, superior cosmetic finishes (especially plating), net-shape precision, and projects where long tool life is a major cost driver.

- Choose Aluminum for applications requiring light weight, higher strength-to-weight ratio, or better performance at elevated temperatures.

Sometimes, a project may start in Zamak for its low tooling investment and then migrate to Aluminum if the product’s requirements change towards lighter weight or higher operating temperatures.

FAQs

Work With CastMold on Your Next Zamak Project

From initial design for manufacturability (DFM) reviews to process validation and high-volume mass production, CastMold provides a complete, one-stop solution for zinc die casting. Our expertise in tooling, process control, and surface finishing ensures your parts meet the highest standards of quality and performance.

If you are looking for a reliable die casting partner for your project, contact us today for a free quote and design review.