When selecting a material for high-pressure die casting (HPDC), A380 aluminum alloy is often the default, go-to choice for engineers worldwide. Its widespread adoption is no accident; A380 offers an exceptional combination of mechanical properties, castability, and cost-effectiveness that makes it suitable for a vast range of applications.

However, “default” doesn’t mean “universal.” Understanding A380’s precise characteristics—and its limitations—is crucial for optimizing your part’s performance, cost, and manufacturability. This guide provides a deep dive into A380’s properties, its relationship to other alloys, and critical design considerations.

- What is A380 Aluminum Alloy? Why It’s the “Default” HPDC Alloy

- Aluminum A380 Component Elements Propertiesn

- Mechanical Properties

- Physical Properties

- A380 vs Other Die-Casting Alloys

- Surface Finishing Options for A380

- Design for Manufacturability (DFM) with A380

- When NOT to Use A380 aluminum alloy

- Applications & Case Notes

- FAQs

- Get a Part Review

- Aluminum Die Casting Services

What is A380 Aluminum Alloy? Why It’s the “Default” HPDC Alloy

A380 is an aluminum alloy belonging to the Al-Si-Cu family. Its designation signifies a composition primarily of aluminum, with significant additions of silicon (Si) and copper (Cu). As noted by the North American Die Casting Association (NADCA), A380 is the most widely specified die casting alloy due to its excellent synergy of properties:

- Great Castability: It flows well into complex mold geometries.

- Good Mechanical Properties: It offers a solid balance of strength and hardness for many structural and mechanical components.

- Good Thermal Conductivity: It efficiently dissipates heat, ideal for housings and enclosures.

- Cost-Effective: Its widespread use and recycled content keep it economical.

Where A380 Fits in Al–Si–Cu (3xx.x) Families

The 3xx.x series of aluminum alloys are characterized by silicon and copper as the main alloying elements. Silicon improves fluidity and reduces solidification shrinkage, which is vital for the high-speed HPDC process. Copper increases strength and hardness, but can slightly reduce ductility and corrosion resistance. A380 sits at a sweet spot within this family, providing a robust, all-around performance profile that serves as a benchmark for other alloys.

The performance of A380 is directly tied to its elemental composition. The following table outlines the standard ranges according to ASTM B85.

| Element | Spec (typical %) |

|---|---|

| Si | 7.5 – 9.5 |

| Cu | 3.0 – 4.0 |

| Fe | ≤ 1.3 |

| Mg | ≤ 0.10 |

| Mn | ≤ 0.50 |

| Ni | ≤ 0.50 |

| Zn | ≤ 3.0 |

| Sn | ≤ 0.35 |

| Others (each / total) | ≤ 0.10 / ≤ 0.50 |

Mechanical Properties

These properties define how A380 behaves under load and are critical for structural applications.

| Property | Value | Design Significance |

| Ultimate Tensile Strength (UTS) | 324 MPa (47 ksi) | The maximum stress the material can withstand before fracture. A key indicator for load-bearing capacity. |

| Yield Strength (YS) | 159 MPa (23 ksi) | The stress at which the material begins to deform permanently. Essential for designing parts that must not bend under normal use. |

| Hardness (Brinell) | 80 HB (500 kg load, 10 mm ball) | Measures resistance to indentation and wear. A higher value means better scratch and wear resistance. |

| Elongation at Break | 3.5% | Indicates ductility. A value of ~3.5% means A380 is relatively brittle; features like snap-fits or thin clips are prone to fracture and require careful design. |

Thin-wall vs. Standard Sections

It’s important to note that mechanical properties are sensitive to wall thickness. Thinner sections cool faster, resulting in a finer grain structure and slightly higher strength and hardness. However, they are also more susceptible to casting defects like misruns or cold shuts if process parameters are not perfectly controlled.

Physical Properties

Physical properties determine how A380 interacts with its environment, particularly concerning heat and electricity.

| Property | Value | Design Significance |

| Density | 2.71 g/cm³ (0.098 lb/in³) | Relatively lightweight, contributing to weight savings in automotive and portable device applications. |

| Thermal Conductivity | ~96 W/m·K | Good for heat dissipation. For heat sinks or electronic enclosures, this property allows for effective thermal management. Wall thickness and cooling fins should be designed to leverage this. |

| Electrical Resistivity | ~7.5 µΩ·cm | A moderate conductor. Not ideal for pure electrical conductivity applications but sufficient for grounding and shielding. |

| Modulus of Elasticity | ~71 GPa (10.3 x 10⁶ psi) | Measures the material’s stiffness. A consistent value is crucial for predicting deflection under load. |

A380 vs Other Die-Casting Alloys

Choosing the right alloy often involves trade-offs. Here’s how A380 compares to other common choices.

| Scenario / Requirement | Prefer… | Why |

| General-purpose parts; good balance of castability and strength | A380 | Default for broad applications; easy to cast with robust properties. |

| Better corrosion resistance and higher strength at elevated temperature | A360 | Improves corrosion/high-temp behavior vs. A380; somewhat harder to cast. |

| Very intricate/thin-wall parts, better die filling; common JIS pick | A383 / ADC12 | Improved die fill and hot-crack resistance; often machines well. (Gabrian) |

| Leak-tight hydraulic/pneumatic housings | A413 | Excellent pressure tightness when designed/cast correctly. |

| High wear resistance needed (e.g., sliding surfaces) | B390 | Very high wear resistance/hardness but low ductility—design accordingly. |

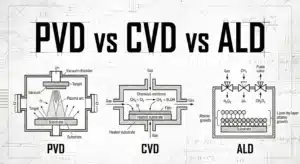

Surface Finishing Options for A380

A raw A380 casting has a good surface finish, but many applications require post-processing for cosmetic, protective, or functional reasons.

- Powder Coating & Painting: These are the most common and effective finishing methods for A380. They provide excellent corrosion protection and a wide range of decorative colors and textures. Proper pre-treatment (cleaning and chromate conversion coating) is essential for adhesion.

- Anodizing: Anodizing A380 is possible but challenging. The high silicon content causes the resulting anodic film to be a dark gray, non-uniform color. It provides some corrosion and wear resistance but is not suitable for decorative applications where a clear or brightly colored finish is desired. For cosmetic anodizing, a low-silicon alloy like 518 is a much better choice.

- Plating: A380 can be plated with nickel, chrome, or other metals, but it requires a specialized multi-step pre-treatment process (including a zincate layer) to ensure adhesion.

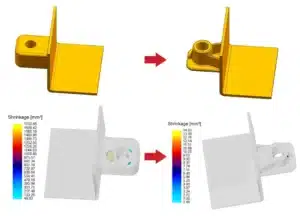

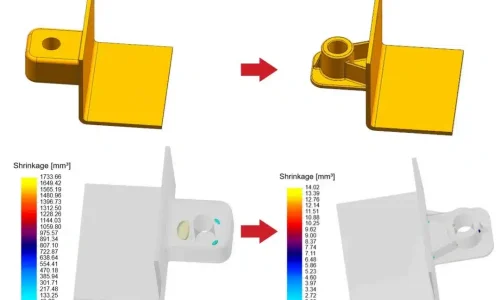

Design for Manufacturability (DFM) with A380

Good part design is the key to avoiding casting defects.

Wall Thickness, Ribs, Fillets & Draft

- Wall Thickness: Aim for uniform wall thickness, typically between 1.5 mm and 3.0 mm. Avoid abrupt changes.

- Ribs: Use ribs to increase stiffness instead of thickening entire walls. Rib thickness should be ~50-80% of the adjoining wall thickness.

- Fillets: Generous inside and outside radii (fillets) are critical. They improve metal flow, reduce stress concentrations, and prevent cracking. A minimum radius of 1.0 mm is a good starting point.

- Draft Angles: A draft angle of 1-2 degrees on all surfaces parallel to the die opening is necessary for easy part ejection.

Common Defects & Prevention

| Defect | Design/Process Cause | Prevention Strategy |

| Porosity (Gas/Shrinkage) | Trapped air; non-uniform solidification. | Add overflows and vents; use vacuum-assisted HPDC; ensure uniform wall thickness; optimize gate location. |

| Hot Cracking | Stress during solidification in constrained areas. | Add generous fillets; avoid sharp internal corners; switch to an alloy with a narrower freezing range like A383/ADC12. |

| Misrun / Cold Shut | Incomplete filling of the mold cavity. | Increase wall thickness; shorten flow length; optimize gating and venting; increase injection speed/pressure. |

Strategies for Leak-Tight Components

For applications requiring pressure tightness (e.g., valve bodies), A380 can be challenging due to potential microporosity.

- Design Optimization: Prioritize uniform walls and smooth flow paths.

- Process Control: Vacuum-assisted die casting is highly recommended to minimize gas porosity.

- Testing: Each part should be pressure tested (e.g., with air-under-water or helium leak testing).

- Impregnation: As a final step, sealing the part with a resin (impregnation) can be used to salvage parts with minor leaks, though it’s best to solve the issue in the casting process itself.

When NOT to Use A380 aluminum alloy

Summarizing the points above, you should actively look for an alternative to A380 when your design’s top priority is:

- High Corrosion Resistance: Choose A360.

- High Strength at High Temperatures: Choose A360.

- High Wear Resistance: Choose B390.

- Decorative Anodized Finish: Choose a 5xx series alloy.

- Extreme Die-Fill Complexity: Choose ADC12 / A383.

- Maximum Pressure Tightness: Choose A413.

Applications & Case Notes

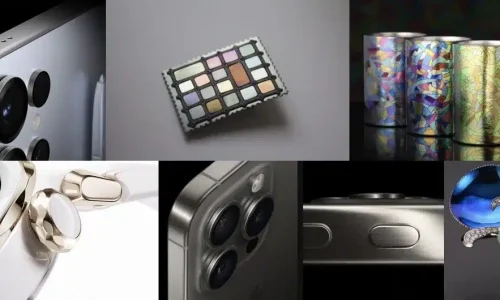

A380’s versatility makes it ubiquitous across industries:

- Automotive: Engine brackets, transmission housings, oil pans.

- Electronics & Communications: Heatsinks, telecom chassis, LED lighting fixtures.

- Power Tools: Motor housings, gear cases, handles.

- General Machinery: Brackets, housings, structural components.

FAQs

Get a Part Review

Navigating alloy selection and design for manufacturability can be complex. Our engineering team is here to help you achieve precision from design to delivery. Upload your CAD file for a complimentary part review, and we’ll provide feedback on material selection, DFM optimization, and cost-saving opportunities.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.