Capabilities

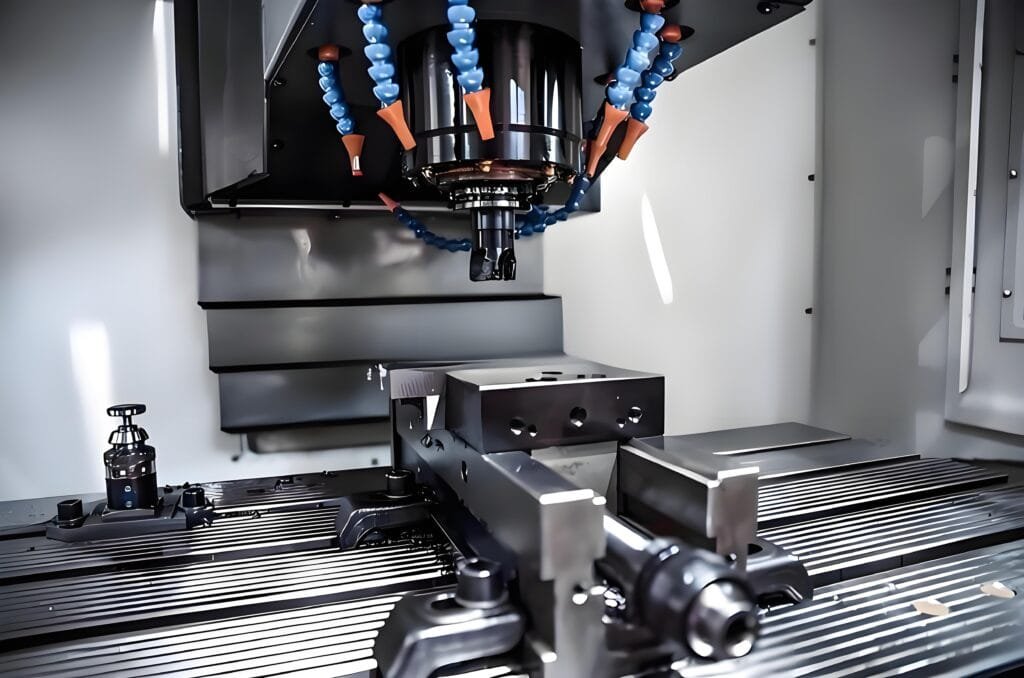

Precision Secondary CNC Machining Services

From Prototyping to High-Volume Production

Achieve ±0.01mm Tolerances with Post-Processing for Critical Features (Drilling, Tapping, Surface Finishing)

ISO 9001:2015

certified QMS

Lead times

as short as 1 day.

End-to-End Assembly Solutions

Flexible MOQ

from 50pcs

Triple Verification

(Manual + Laser + CMM)

What is

Precision CNC Machining

Precision CNC machining utilizes computer-numerical-control systems to manufacture components with micron-level accuracy for mission-critical applications in aerospace, medical instruments, and industrial automation. By executing digital designs with extreme consistency, it achieves dimensional tolerances as tight as ±0.005mm on complex geometries like hydraulic valve bodies, surgical tooling, and optical alignment fixtures – surpassing conventional machining capabilities.

With 5-axis simultaneous machining and real-time quality monitoring, this process ensures near-zero defect rates from prototype validation to mass production. Components such as precision gears, sensor housings, and fluidic connectors maintain strict compliance with functional specifications under ISO 9001:2015 certified quality systems.

CastMold specializes in automotive-grade precision machining with 10+ years of Tier-1 supplier experience, delivering components that withstand extreme temperature cycles and vibration loads in modern vehicle systems.

Our CNC Machining Services

CNC Milling

CNC Turning

Gear Hobbing

Wire EDM

Mirror EDM

CNC Milling Service

CastMold’s multi-axis milling machines guarantee CNC parts with tight tolerances and precise dimensions. This technology delivers precision tailored to your needs, ideal for iterations and new products. Compatible with a broad material range, from metals to composites, our CNC milling boasts efficiency, having parts ready swiftly.

- Material Compatibility: Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics

- Milling Operations: Face Milling, Profile Milling, Pocket Milling, Complex Surface Milling, Drilling, Boring

- Tolerance: ± 0.0005 inches (0.0127 mm) or better (specific to material and operation)

- Maximum Workpiece Size: X: 40 inches (1016 mm) Y: 20 inches (508 mm) Z: 25 inches (635 mm) or specific to machine capacity

- Axis: 2-axis, 3-axis, multi-axis turning capability

CNC Turning Services

CNC Turning is a computer-controlled machining process that rotates a workpiece while a stationary tool removes material to create cylindrical or conical parts. It delivers high precision (±0.01mm), repeatability, and complex geometries for components like shafts or bushings in industries such as automotive and aerospace. Compatible with metals, plastics, or composites, it supports rapid prototyping and mass production.

- Material Compatibility: Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics

- Turning Operations:External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading

- Tolerance: ± 0.0005 inches (0.0127 mm) or better (specific to material and operation)

- Maximum Workpiece Diameter: 20 inches (508 mm) or specific to machine capability

- Maximum Workpiece Length: 60 inches (1524 mm) or specific to machine capability

- Axis: 2-axis, 3-axis, multi-axis turning capability

Gear Hobbing Services

Gear Hobbing is a machining method using a rotating hob to cut gears, splines, or sprockets. The hob and workpiece synchronize rotation, generating precise involute profiles. Efficient for high-volume production of spur, helical, or worm gears, it works with metals and plastics. Widely used in automotive and aerospace, CNC hobbing enables multi-axis automation for speed and accuracy.

- Material Compatibility: Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics

- Turning Operations:External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading

- Tolerance: ± 0.0005 inches (0.0127 mm) or better (specific to material and operation)

- Maximum Workpiece Diameter: 20 inches (508 mm) or specific to machine capability

- Maximum Workpiece Length: 60 inches (1524 mm) or specific to machine capability

- Axis: 2-axis, 3-axis, multi-axis turning capability

Wire EDM Services

Wire EDM uses a charged wire (e.g., brass) to cut conductive materials via CNC-controlled spark discharge. Ideal for hard metals (titanium, tool steel), complex contours, and micro-features with no mechanical stress. Applied in tool/die, aerospace, and medical industries; supports multi-axis machining and automation.

- Material Compatibility: Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics

- Turning Operations:External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading

- Tolerance: ± 0.0005 inches (0.0127 mm) or better (specific to material and operation)

- Maximum Workpiece Diameter: 20 inches (508 mm) or specific to machine capability

- Maximum Workpiece Length: 60 inches (1524 mm) or specific to machine capability

- Axis: 2-axis, 3-axis, multi-axis turning capability

Mirror EDM Services

Mirror EDM achieves extremely low surface roughness (Ra < 0.1μm) with near-mirror finish through ultra-fine discharge parameters and precision electrodes (e.g., graphite, copper). Ideal for high-gloss molds (plastic injection, die-casting), optical components, and applications requiring minimal post-processing polishing. It enables intricate curved surface machining but demands high-precision CNC control and multiple discharge finishing passes to refine details.

- Material Compatibility: Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics

- Turning Operations:External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading

- Tolerance: ± 0.0005 inches (0.0127 mm) or better (specific to material and operation)

- Maximum Workpiece Diameter: 20 inches (508 mm) or specific to machine capability

- Maximum Workpiece Length: 60 inches (1524 mm) or specific to machine capability

- Axis: 2-axis, 3-axis, multi-axis turning capability

CastMold

Precision Machining Solutions

Prototyping

Rapid Prototyping

Leverage our robust manufacturing capabilities for swift, high-quality prototype delivery. Using the latest technology, we ensure rapid, accurate production, expediting your path from testing to market.

Capability: 20-500

Lead Time: 10 business days

Prouduction

Low and High-Volume Production

CastMold is equipped to handle large-scale production orders. This means they can efficiently produce large quantities of CNC precision machining parts without compromising quality or accuracy.

Capacity: 1000+

Lead Time: 15 business days

Precision CNC Machining Tolerances

|

|

Typical Tolerance (mm)

|

Best Possible Tolerance (mm)

|

Notes

|

|---|---|---|---|

|

EDM (Electrical Discharge Machining) |

±0.015 |

±0.005 |

Tolerance can be affected by electrode wear. |

|

Grinding |

±0.005 |

±0.001 |

Surface finish is typically smoother with grinding. |

|

CNC Turning |

±0.025 |

±0.010 |

Finish can impact tolerance. |

|

CNC Milling |

±0.025 |

±0.005 |

Precision can vary based on tool type and material. |

CNC Machining Parts Made By CastMold

FAQs

We primarily use Zamak 2, Zamak 3, Zamak 5 and Zamak 7, offering tensile strength from 190 to 255 MPa, Brinell hardness HB80–HB100, and elongation of 5–10%.

Zinc alloys generally enable lower tooling costs and finer feature detail, with part-unit cost comparable—or even lower—for small to medium runs, while aluminum may be more economical at very high volumes due to material pricing.

We routinely cast down to 0.4 mm wall thickness; standard dimensional tolerance is ±0.1 mm for features under 50 mm and ±0.2% for larger sections.

We support powder coating, electro-plating (nickel, chrome, zinc), painting, anodizing, and polishing—each tailored for adhesion, corrosion resistance, and appearance.

Our MOQ is 500 pcs. We offer tiered pricing: standard rates for 500–2,000 pcs, above 5,000 pcs and custom quotes for larger runs.

From mold design to first samples typically takes 15–20 days; mass production lead time is 20–30 days, depending on order size and finish complexity.

Typical mold cost ranges depending on cavity count and complexity. We can amortize mold cost over the part price or hold the tool for future runs.

We perform CMM, X-ray/CT, hardness, salt spray, 2D vision, and caliper checks. Full inspection reports with data sheets are provided per batch.

Yes. Our alloys and processes fully comply with RoHS, REACH, and other global environmental standards. We also recycle scrap material to minimize waste.

Bare zinc alloy has moderate corrosion resistance; with proper electro-plating or powder coating, parts pass 500 + hours salt spray tests for long-term outdoor use.