Aluminum heat treatments aren’t a single recipe—they’re a toolkit you dial in to control strength, ductility, dimensional stability, and long-term reliability. If you cast or machine aluminum parts (and especially if you handle both casting and wrought routes), knowing when to anneal, homogenize, solution heat treat, quench, and age is the difference between first-time-right and costly rework. This guide maps the full sequence, explains the practical temper choices (T4/T5/T6/T7), and clarifies what changes between sand/permanent-mold castings, high-pressure die castings (HPDC), and wrought alloys.

- Can Aluminum be Heat Treated?

- How to heat treat Aluminum (Anneal → Homogenize → Solution → Quench → Aging)

- Temper Systems You’ll Actually Use (T4/T5/T6/T7)

- Casting vs. Wrought: What Changes in Practice?

- Furnace Accuracy & Quality Gates

- Practical Windows & Pitfalls (Checklist)

- Typical Routes by Alloy/Process (Quick Reference)

- 常见问题

- Final Word

- Aluminum Die Casting Services

Can Aluminum be Heat Treated?

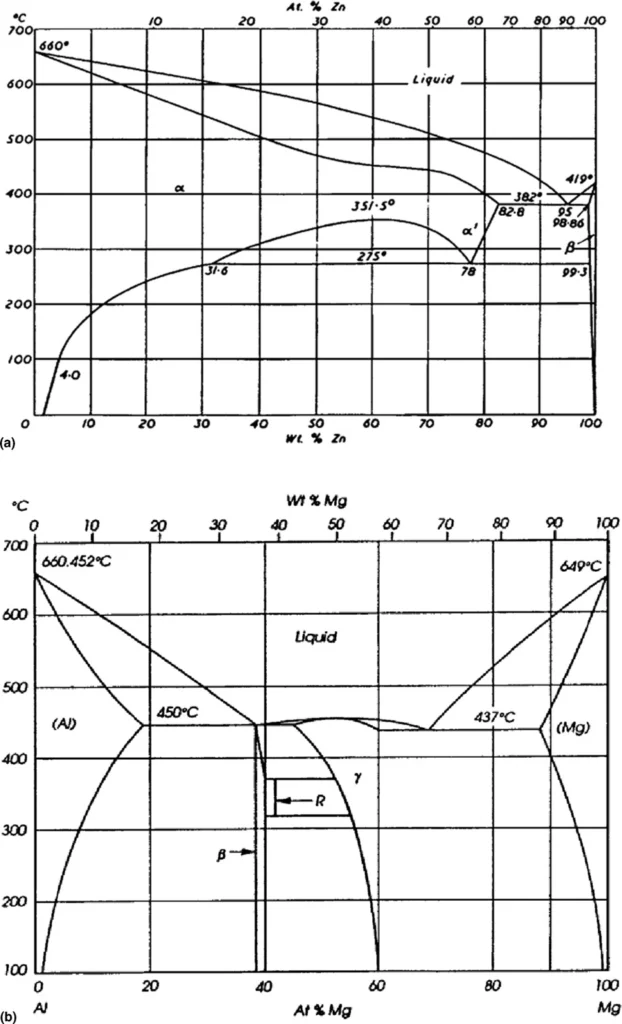

Heat treating aluminum means controlled heating and cooling to alter its microstructure and, in turn, its mechanical properties and stability. Unlike steels—which lean on phase transformations—aluminum’s hardening engine is solution heat treatment → rapid quench → aging (precipitation hardening). Not all series respond:

- Commonly heat-treatable families: 2xxx (Al-Cu), 6xxx (Al-Mg-Si), 7xxx (Al-Zn-Mg-Cu), 8xxx (select), parts of 4xxx.

- Non-heat-treatable families: 1xxx, 3xxx, 5xxx—these rely on work hardening and annealing rather than precipitation hardening.

In practice:

- Castings may use anneal/stress relief, homogenizing (to reduce segregation), then solution → quench → age (where alloy/process allow).

Wrought parts rely on tight solution/quench/age control, pyrometry compliance, and fixturing to tame distortion.

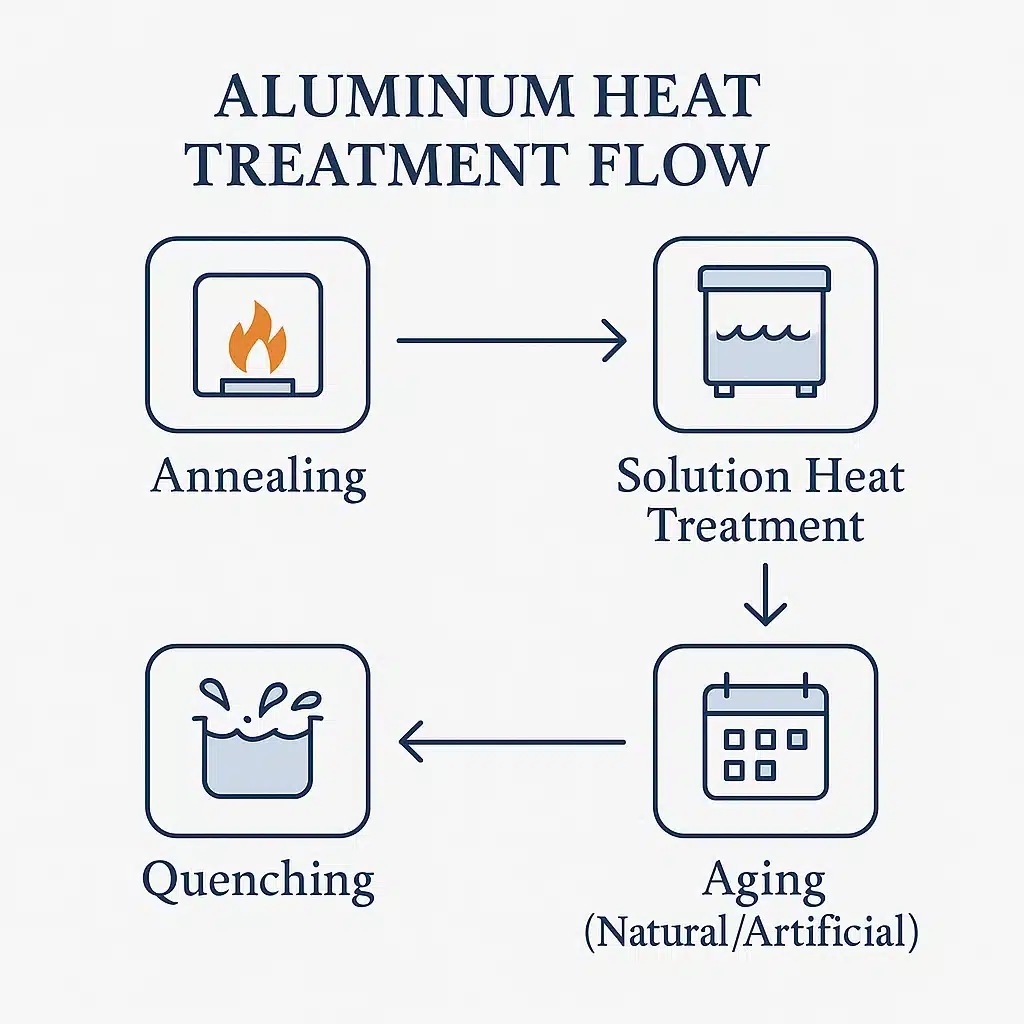

How to heat treat Aluminum (Anneal → Homogenize → Solution → Quench → Aging)

Below is the practical sequence most engineering teams standardize around.

Annealing (Stress Relief & Formability)

- Purpose: Reduce residual stress, restore ductility after cold work, improve machinability, and stabilize dimensions before tight-tolerance machining.

- Typical window: 300–410 °C (570–770 °F) for 0.5–3 h, tailored to section thickness, alloy, and distortion sensitivity.

Homogenizing (Castings Only)

- Purpose: Reduce micro-segregation from solidification, improving consistency before solution treatment and machining.

- Typical window: ~480–540 °C (900–1000 °F) near the solidus with controlled soak and slow cool.

Homogenizing (Precursor to T4/T6/T7)

- Purpose: Dissolve strengthening elements (Mg, Si, Cu, Zn) into solid solution for later precipitation.

- Typical window: ~440–525 °C (825–980 °F) depending on alloy.

- Uniformity & soak: Keep furnace uniformity tight (aim ±5–±10 °C). Soak time starts when the coldest point reaches setpoint; thin sections may need minutes, while thick sections often use the rule of ~1 h per inch as a starting point.

(a) Aluminum–zinc equilibrium phase diagram. (b) Aluminum–magnesium equilibrium phase diagram.

Quenching (Speed Matters)

- Purpose: “Freeze” the supersaturated solid solution to enable age hardening.

- Logistics: Engineer the layout for furnace-to-quench transfer ≤ ~15 s (drop-bottom or near-furnace tanks).

- Media: Water is standard; hot/boiling water (≈65–100 °C / 150–212 °F) or polymer quenchants help balance distortion vs. properties on complex or mixed-section parts.

Aging (Natural vs. Artificial)

- Natural aging (NA): At room temperature, many alloys achieve ~90% of NA strength in ~24 h, stabilizing by 4–5 days. Perform straightening/forming immediately after quench for best results.

Artificial aging (AA):~115–240 °C (240–460 °F) for 6–24 h, alloy-dependent. Increases strength and tightens scatter, with a modest trade in ductility.

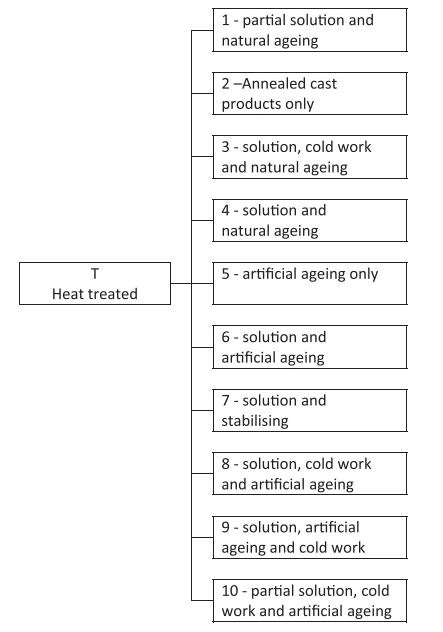

Temper Systems You’ll Actually Use (T4/T5/T6/T7)

- O / W / T vocabulary:

- O = annealed

- W = solution-treated, not aged

- T = aged (naturally or artificially), often after solution treatment

- T4: Solution heat treated + natural age. Good formability post-quench; strength develops over several days.

- T5: No solution step; artificially aged from the as-cast or as-formed condition. A favorite for HPDC aluminum to stabilize dimensions and bump strength without risking blistering.

- T6: Solution heat treated + quench + artificial age for maximum strength. Great for A356 sand/permanent-mold castings and many wrought alloys. For HPDC, only pursue if porosity is very low (e.g., vacuum die casting), and you’ve proven no blister/distortion.

- T7: Over-aged/stabilized condition. Used to minimize growth and drift at elevated temperatures (common on some castings that must hold shape in service).

Casting vs. Wrought: What Changes in Practice?

Sand & Permanent-Mold Castings (e.g., A356/A357)

- Typical T6 route: Solution ~540 °C (~1000 °F) for 6–12 h → water quench → artificial age ~155–175 °C (311–347 °F) for 4–8 h.

- Why it works: Lower porosity than HPDC lets you run full T6 without blistering; delivers strong, ductile parts (think wheels, structural arms, brackets).

High-Pressure Die Castings (HPDC) (e.g., A380/ADC12)

- Reality: HPDC has micro-porosity from high-speed fill; full T6 risks blistering and warpage.

- Common path: T5 artificial aging (e.g., 175–230 °C / 347–446 °F for 4–6 h) to stabilize and lift properties.

- When T6? Only with vacuum HPDC + impregnation or extremely low porosity + controlled trials. Otherwise, design strength into ribs/webs and rely on T5.

Wrought Alloys (e.g., 6xxx / 2xxx / 7xxx)

- Playbook: Tight solution-quench-age control, strong pyrometry discipline, and AMS2750 furnace compliance (calibration, TUS/SAT, instrument classes).

Watch outs: Transfer times, quench agitation, aging oven uniformity, and fixture design drive distortion and property scatter.

Furnace Accuracy & Quality Gates

- Pyrometry discipline: Treat temperature uniformity as a spec, not an aspiration (e.g., aim ±6–±10 °C class depending on criticality). Calibrate thermocouples and schedule regular TUS/SAT.

- Quench engineering: Minimize path length and time; size tanks for load; control media temperature and agitation; standardize part orientation and spacing.

- Quality gates:

- Time-stamp oven-to-quench transfers

- Hardness mapping (and %IACS conductivity on appropriate alloys)

- Tensile pulls for lot qualification on critical programe

- Dimensional re-inspection post-age (bores, flats, GD&T features)

For castings: defined X-ray/CT sampling plans where porosity affects downstream heat treatment

Practical Windows & Pitfalls (Checklist)

Do:

- Keep solution temperature in a narrow band (±5–±10 °C) and start soak when the cold spot is at temperature.

- Engineer fixtures to control distortion; consider quench orientation 和 aging in fixture for flatness-critical parts.

- Place quench tanks adjacent to the furnace or use drop-bottom systems to hit transfer targets.

- For castings, simulate solidification to inform heat-treat strategy (hot spots, feeding aids, chill placement).

Don’t:

- Don’t delay quench or route parts through long corridors; seconds matter.

- Don’t force T6 on porous HPDC—use T5 and design strength into ribs/webs, or qualify vacuum HPDC first.

- Don’t overload baskets; avoid “heat shadows” and airflow dead zones.

Don’t assume one cycle fits all; document alloy- and geometry-specific windows.

Typical Routes by Alloy/Process (Quick Reference)

| Process / Alloy | Typical Heat-Treat Route (evidence-guided) | Notes |

|---|---|---|

| Sand/PM — A356/A357 | T6: SHT near solidus with sufficient soak → rapid quench (often warm/boiling water) → AA per property target | Casts need longer/hotter SHT vs wrought; warm quench reduces stresses. |

| HPDC — A380/ADC12 | T5 from as-cast (no SHT) for stability and property lift | Avoid blistering from trapped gas at SHT; validate vacuum HPDC if piloting T6. |

| Wrought — 6061/6082 | SHT (rapid, uniform) → immediate quench → AA (T6/T651) | 6082 is SHT-temperature sensitive; control logistics via Table 9 soak/delay guidance. |

| Wrought — 2024/7075 | SHT → quench → T6/T73 per SCC/toughness needs; advanced RRA (retrogression-re-aging) blends T6 strength with T73 SCC resistance | RRA sequence described for 7xxx. |

常见问题

On standard HPDC, usually no—porosity risks blistering and warpage. Use T5 for stabilization. Pursue T6 only with vacuum HPDC and rigorous qualification.

Hot/boiling water can reduce residual stress and distortion on complex castings, trading a small strength delta for dimensional control.

Design for ≤ ~15 s furnace-to-quench, with controlled media temperature and vigorous agitation. Layout matters as much as the recipe

Most heat-treatable alloys reach ~90% of NA strength in ~24 h, stabilizing by 4–5 days. Plan straightening/forming right after quench

Final Word

If you remember only three things about aluminum heat treatments: keep temperature windows tight, engineer the quench logistics as deliberately as you engineer the part, and choose the temper that fits the process and alloy (T5 for most HPDC, T6 for low-porosity castings and wrought). Do that, and your aluminum parts stop being unpredictable—and start being reliably strong, stable, and production-ready.

Work with CastMold

If you need stable T5 on HPDC, validated A356-T6 windows, or a furnace-to-quench workflow that holds tolerances, bring CastMold in early. We’ll help you lock the design-for-heat-treat strategy from concept to SOP—so your parts perform on paper 和 on the floor.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.