Die casting is an advanced metal forming process that uses high pressure to inject molten metal into a precise, reusable steel mold (known as a “die”). This process enables the efficient, high-volume production of metal parts with complex geometries, high dimensional accuracy, and an excellent surface finish. This guide will provide a comprehensive analysis of the die casting process, its core types, common materials, key applications, cost structure, and its advantages and disadvantages to inform your manufacturing project decisions.

Key Takeaways

- Die casting is a manufacturing process where molten metal is injected under high pressure into a mold, enabling the mass production of high-precision, net-shape or near-net-shape metal parts.

- The main processes are Hot-Chamber Die Casting (for low-melting-point alloys like zinc) and Cold-Chamber Die Casting (for high-melting-point alloys like aluminum), with the choice directly impacting production efficiency and material scope.

- Common materials include aluminum alloys (e.g., A380, ADC12), zinc alloys (e.g., Zamak 3, Zamak 5)和 magnesium alloys (e.g., AZ91D), each offering unique performance advantages.

- Die casting is a cornerstone of the automotive, consumer electronics, aerospace, and telecommunications industries, used to manufacture critical components from engine blocks to mobile phone casings.

- Its core advantages are extremely high production efficiency and part precision, but this is accompanied by a high initial tooling investment, making it most suitable for large-scale production to achieve economies of scale.

- Key Takeaways

- What Is Die Casting?

- The Detailed Die Casting Process

- Types of Die Casting: Hot-Chamber vs. Cold-Chamber

- A Guide to Common Die Casting Materials

- Applications of Die Casting Technology

- Detailed Analysis of Die Casting Advantages and Disadvantages

- How to Optimize Costs and Return on Investment (ROI)

- A Guide to Surface Finishes for Die-Cast Parts

- Comparing Casting Processes: Die Casting vs. Other Methods

- Why Choose Our Company for Die Casting Services?

- 共同创造卓越

What Is Die Casting?

Die casting is a metal casting process characterized by forcing molten non-ferrous metals under high pressure into a mold cavity created by two hardened tool steel dies. This high pressure is the key differentiator from other casting methods, ensuring that the liquid metal rapidly fills every minute detail of the mold, thereby producing parts with extremely high dimensional consistency and an excellent surface finish.

The history of die casting dates back to the mid-19th century, initially developed to solve the mass production challenge of movable type for the printing industry. In 1849, a patent was granted for a small, hand-operated machine for the mechanized production of printing type, which is widely recognized as the beginning of the modern die casting industry. The technology’s core value—mass-producing complex and consistent parts—was established from its inception. In the 20th century, with the rise of consumer goods like phonographs, typewriters, and early automobiles, the applications of die casting expanded rapidly. For instance, as early as 1903, the carburetor body for Cadillac was produced using die casting. Today, driven by modern technologies like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), the precision and efficiency of the die casting process have reached unprecedented heights, making it an indispensable part of high-tech manufacturing.

The Detailed Die Casting Process

Understanding the complete cycle of die casting, from raw material to a finished precision part, is crucial for evaluating its suitability for your project. Although hot- and cold-chamber processes differ in detail, the core process generally follows these six key steps. This series of interconnected stages collectively determines the quality, cost, and production efficiency of the final part.

1. Die Preparation & Clamping

The process begins with thoroughly cleaning the internal cavities of the two die halves (the cover die and the ejector die) and spraying them with a release agent or lubricant. This lubricant not only helps control the mold’s temperature but, more critically, ensures that the solidified casting can be smoothly ejected later. Once prepared, the die casting machine applies immense force to clamp the two die halves tightly together, preparing for the high-pressure injection.

2. Metal Melting & Injection

Depending on the process type, the metal is heated to a molten state either within the machine (hot-chamber) or in a separate furnace (cold-chamber). The liquid metal is then fed into a shot chamber. Here, a plunger or piston forces the molten metal into the closed die cavity at extremely high speed and pressure (ranging from 1,000 psi to over 25,000 psi). This high-speed, high-pressure injection is the essence of the die casting process, ensuring the metal flow fills all complex structures and thin-walled sections of the mold.

3. Cooling & Solidification

Upon entering the mold cavity, the hot molten metal comes into contact with the cooler mold walls and begins to cool and solidify rapidly, precisely replicating the mold’s shape. During this time, the die remains clamped under high pressure to resist the internal stresses that can arise from metal shrinkage during solidification, preventing defects like porosity. To enhance production efficiency, molds are often designed with internal cooling channels that circulate water or oil to accelerate the cooling process.

4. Ejection

Once the casting has fully solidified, the die casting machine opens the mold. The casting will remain in the ejector half of the die. The machine’s ejector mechanism, typically consisting of several “ejector pins,” then activates to smoothly push the casting out of the die cavity. The draft angle designed into the mold and the previously applied lubricant are crucial at this stage, ensuring a smooth ejection without damaging the part or the mold.

5. Trimming & Shakeout

The ejected part is not yet the final product; it is attached to a gating system, which includes the sprue, runners, gates, and potentially overflow flash (thin metal formed at the mold’s parting line). This entire unit is called a “shot.” The subsequent trimming process separates the main part from this excess metal. This can be done using manual tools, a trim die in a press, or tumbling.

6. Finishing & Post-Processing

Thanks to the die casting process, many parts have a sufficiently smooth surface and precise dimensions after trimming, requiring no further processing. However, for projects with higher requirements, secondary operations may be necessary, such as CNC machining to create threaded holes or achieve tighter tolerances, as well as polishing, powder coating, plating, or anodizing to meet final product specifications.

Types of Die Casting: Hot-Chamber vs. Cold-Chamber

The die casting process is primarily divided into two major categories: hot-chamber and cold-chamber die casting. The fundamental difference between them lies in the relationship between the melting furnace and the die casting machine, as well as the method of metal injection. This choice is not arbitrary but is strictly determined by the melting point and chemical properties of the alloy being used, directly affecting production efficiency, equipment lifespan, and the range of processable materials.

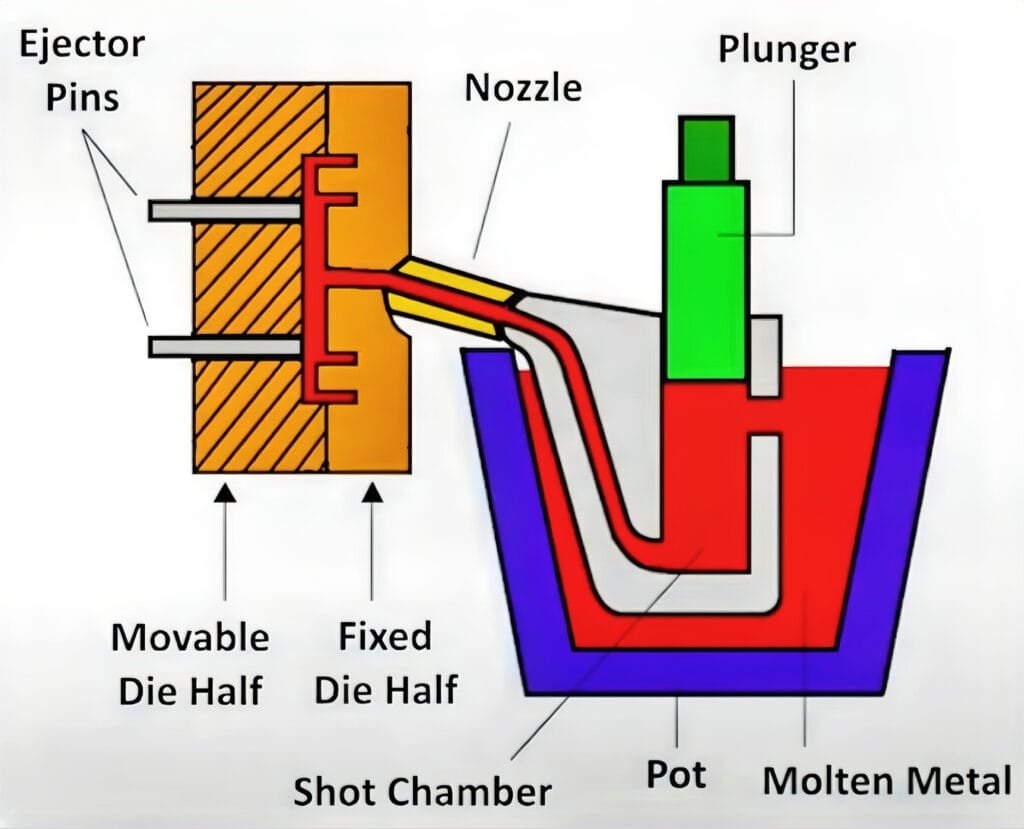

Hot-Chamber Die Casting

Definition & Process

In hot-chamber die casting, the “gooseneck” of the injection mechanism is immersed directly in a pool of molten metal, which is an integral part of the casting machine itself. During operation, a plunger retracts, allowing the molten metal to automatically fill the gooseneck; when the plunger descends, the liquid metal is forced directly into the die cavity.

优势

Because the metal supply system is integrated into the machine, the step of ladling metal from an external furnace is eliminated. This results in extremely fast production cycles for hot-chamber die casting, often completing 15 or more shots per minute. This high efficiency provides a significant cost advantage. Additionally, since the liquid metal has minimal exposure to air, the risk of oxidation and impurity contamination is lower.

Applicable Alloys & Applications

The limitation of this process is that the high-temperature molten metal continuously erodes the injection components. Therefore, it is only suitable for alloys with low melting points and low corrosivity to iron components. The most typical examples are zinc alloys (Zamak series), and it is also used for some magnesium, lead, and tin alloys. Hot-chamber die casting is the ideal choice for mass-producing small to medium-sized parts like zippers, faucet fittings, automotive interior components, and precision electronic parts.

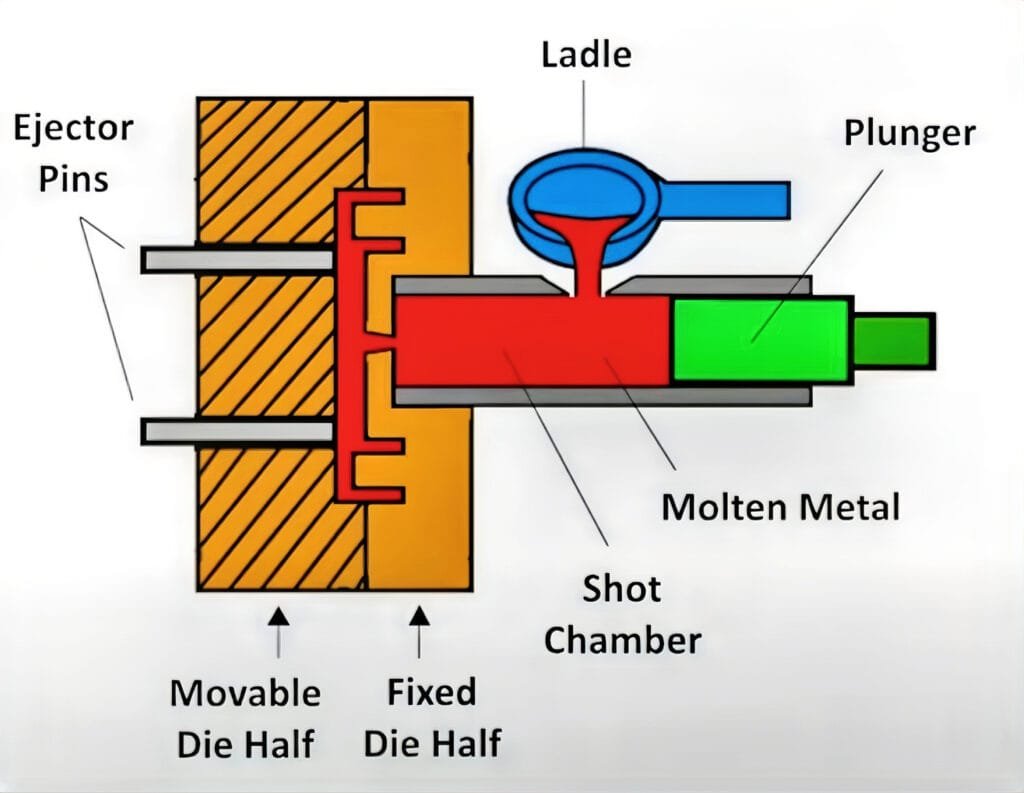

Cold-Chamber Die Casting

Definition & Process

In cold-chamber die casting, the melting furnace is a separate piece of equipment from the casting machine. During operation, a specific amount of molten metal is ladled (manually or automatically) from the furnace and poured into the machine’s “cold chamber” (the shot chamber). A powerful hydraulic plunger then forces this liquid metal into the die at high speed and pressure.

优势

The greatest advantage of cold-chamber die casting is its ability to process high-melting-point alloys. Because the injection system’s plunger and shot chamber are only in brief contact with the hot metal during each shot, the corrosion and wear from long-term immersion are avoided. This allows it to produce parts with higher strength, better heat resistance, and a more robust structure. It can also be used to create larger and denser castings.

Applicable Alloys & Applications

Cold-chamber die casting is the exclusive choice for processing aluminum alloys, which is its most widespread application. It is also suitable for magnesium, copper alloys, and zinc alloys with high aluminum content. With its ability to produce large, high-strength parts, cold-chamber die casting dominates the automotive industry, where it is used to manufacture engine blocks, transmission housings, suspension components, and large structural body parts. It also plays a key role in the aerospace and telecommunications equipment sectors.

Table 1: Comparative Analysis of Hot-Chamber and Cold-Chamber Die Casting

| Feature | Hot-Chamber Die Casting | Cold-Chamber Die Casting |

| Process Principle | Injection system is immersed in molten metal. | Molten metal is ladled into a separate shot chamber. |

| Production Cycle | Very fast (approx. 15+ cycles/minute). | Slower (includes ladling step). |

| Applicable Metals | Low-melting-point alloys: Zinc, some Magnesium, Tin, Lead. | High-melting-point alloys: Aluminum, Copper, Magnesium. |

| Injection Pressure | Lower (1,000–5,000 psi). | Extremely high (up to 25,000+ psi). |

| Part Size | Typically small to medium-sized parts. | Can produce large, complex parts. |

| Core Advantage | Extremely high production efficiency, low unit cost. | Flexible material selection, can produce high-strength parts. |

| Equipment Cost | Equipment and maintenance costs are relatively lower. | Equipment and energy costs are higher. |

Material selection is a critical decision for the success of a die casting project, directly determining the part’s mechanical properties, weight, corrosion resistance, thermal performance, and final cost. Die casting primarily uses non-ferrous metals, with the three major alloy families—aluminum, zinc, and magnesium—dominating the field. The table below details the most common die casting alloys, their properties, and applications to guide your material selection.

Table 2: Guide to Common Die Casting Materials and Their Alloys

| Material Category | Common Alloys | Key Characteristics | Typical Application Areas |

| Aluminum Alloys | A380, ADC12 | The most common die casting alloy. Offers an excellent combination of properties, including light weight, high operating temperature, good corrosion resistance, high strength and stiffness, and good thermal/electrical conductivity. | Engine brackets, transmission housings, electronic enclosures, power tools, furniture parts—extremely wide range of applications. |

| A390 | Excellent wear resistance and high strength, but lower ductility. Developed specifically for automotive engine blocks. | Automotive engine blocks, valve bodies, pump housings. | |

| A360 | Offers better corrosion resistance and pressure tightness than A380, but is slightly more difficult to cast. | Marine components, telecommunications equipment enclosures, parts exposed to corrosive environments. | |

| Zinc Alloys | Zamak 3, Zamak 5 | The easiest alloy to cast. Excellent castability allows for extremely thin walls and complex details; high impact strength, good ductility, and an exceptional surface finish make it ideal for plating and other post-treatments. | The most common zinc alloys. Consumer electronics, bathroom fixtures, decorative hardware, toys, automotive interior components. |

| Zamak 2 | Due to its higher copper content, it is the strongest and hardest alloy in the Zamak series. Often used to make tooling. | Cores for injection molds, high-stress mechanical components. | |

| Magnesium Alloys | AZ91D | The lightest commonly used structural metal. Unmatched strength-to-weight ratio, good castability, and excellent corrosion resistance. | The most common magnesium alloy. Laptop/mobile phone cases, camera bodies, automotive steering wheels, seat frames. |

| AM60 | Excellent ductility, energy absorption, and strength, making it an ideal choice for automotive safety-related components. | Automotive seat frames, instrument panel brackets, steering wheel armatures. |

Applications of Die Casting Technology

With its ability to produce high-strength, lightweight, and complex metal parts, die casting technology has become deeply integrated into various corners of modern industry, serving as an indispensable manufacturing pillar for many sectors. Its applications are concentrated in fields with stringent requirements for volume, precision, and performance. In turn, the development trends in these industries drive the continuous advancement of die casting technology.

This is the largest and most important market for die casting. Driven by the pursuit of fuel efficiency and performance enhancement, automotive lightweighting has become a core trend. Die-cast aluminum and magnesium components, such as engine blocks, transmission housings, oil pans, steering knuckles, sub-frames, and large integrated body structures (like rear floors), significantly reduce vehicle weight while ensuring strength. The rise of

Electric Vehicles (EVs) has further boosted the demand for large, thin-walled, complex one-piece die castings, such as battery trays and motor housings, solidifying die casting’s central role.

In the high-end consumer electronics sector, die-cast parts provide the unique solid feel of metal, precise structural integrity, and excellent heat dissipation. It is widely used to manufacture A/D shells for laptops and high-end tablets, mobile phone mid-frames, camera bodies, and heat sinks for processors. The die casting process can achieve extremely thin wall thicknesses (as low as 0.5mm), which is crucial for increasingly slim electronic products.

5G base stations, servers, and network switches require durable enclosures and internal components with electromagnetic interference (EMI) shielding. Die-cast parts, particularly those made of aluminum alloy, meet these requirements and are commonly used to produce equipment chassis, antenna brackets, RF filter boxes, and heat sinks.

Aerospace

In the aerospace sector, the strength-to-weight ratio is the golden rule determining performance. Die casting produces lightweight yet robust critical components, such as airframe structural parts, engine components, landing gear assemblies, and interior fittings like airline seating. These parts must maintain absolute reliability under extreme temperatures and pressures.

Medical Devices

The medical industry has extremely high standards for part precision, surface quality, and durability. Due to their repeatability and cleanliness, die-cast parts are used to manufacture surgical instruments, diagnostic equipment housings, monitor stands, and hospital bed actuators.

Detailed Analysis of Die Casting Advantages and Disadvantages

Like any manufacturing process, die casting has its unique advantages and limitations. A deep understanding of this balance is key to determining if it offers the best solution for your project. The decision typically hinges on a comprehensive trade-off between production volume, part complexity, performance requirements, and project budget.

Table 3: Advantages and Disadvantages of Die Casting Technology

| Advantages (Pros) | Disadvantages (Cons) |

| Extremely High Production Efficiency: Die casting is highly automated with very short cycle times, making it the ideal choice for mass production. With a sufficiently large volume, the cost per part is extremely low. | High Initial Tooling Costs: Die casting molds are precision-machined from high-grade tool steel, and their design and manufacturing costs are very high. This makes die casting uneconomical for low-volume production or prototyping. |

| Excellent Dimensional Accuracy & Consistency: The tolerances of die-cast parts can be controlled very tightly (e.g., ±0.1mm for the first 2.5cm), and the consistency between batches is extremely high, ensuring part interchangeability. | Potential for Porosity: Because the liquid metal fills the cavity at extremely high speed, it can trap gas from the cavity, forming tiny internal pores. These pores affect the part’s density and typically prevent it from being heat-treated. |

| Ability to Manufacture Complex Shapes & Thin-Walled Structures: High-pressure injection allows the liquid metal to fill extremely complex and detailed mold cavities, enabling the production of parts with very thin walls (down to 0.5mm), which is difficult for many other casting methods to achieve. | Mainly Limited to Non-Ferrous Metals: The die casting process is primarily suitable for relatively low-melting-point non-ferrous alloys like aluminum, zinc, and magnesium. Casting ferrous metals like steel is technically possible but their extremely high melting points would severely shorten the life of the expensive molds, making it commercially rare. |

| Excellent Surface Finish: Die-cast parts have a smooth, flat surface (Ra of 1-2.5 micrometers), which in many cases can eliminate the need for secondary machining or polishing, directly for surface treatment or use. | Part Size and Weight are Limited: While large parts can be produced, the size is ultimately limited by the tonnage and clamping force of the die casting machine. For very large components (like marine engine parts), die casting may not be the best choice. |

| Good Mechanical Properties: The rapid cooling rate results in a fine-grained crystal structure, which imparts high hardness and strength to the parts. | Difficult to Modify Molds: Once the steel mold is manufactured, making significant design changes is extremely difficult and costly. Therefore, the product design must be frozen before tooling begins. |

How to Optimize Costs and Return on Investment (ROI)

- Design for Manufacturability (DFM): This is the most effective and fundamental cost control strategy. Collaborating with die casting engineers during the product design phase to simplify structures, reduce undercuts, maintain uniform wall thickness, and incorporate adequate draft angles can significantly reduce mold complexity and manufacturing costs, as well as shorten production cycles.

- Use of Multi-Cavity Molds: For smaller parts, designing a mold with multiple cavities allows for the production of several parts in a single shot. This multiplies production efficiency and drastically reduces the machine time and labor cost per part.

- Wise Material Selection: Choose the most cost-effective alloy that meets all engineering performance requirements. Avoid “over-engineering” by selecting a material with properties that far exceed the actual needs.

- Optimize the Gating System: A well-designed runner and gate system not only ensures product quality but also minimizes material waste (i.e., reduces the weight of the gating system) and makes subsequent trimming easier, directly saving on material and labor costs.

A Guide to Surface Finishes for Die-Cast Parts

While many die-cast parts have an excellent as-cast finish, most applications require a secondary surface finish to enhance cosmetic appeal, improve corrosion and wear resistance, or seal surface porosity. The choice of finish depends on the alloy, application requirements, and budget.

Mechanical Finishes: These processes physically alter the surface of the part.

- Shot Blasting: This process propels small abrasive particles at high velocity against the part to clean the surface, remove contaminants, and create a uniform matte texture. It is an excellent preparation step for subsequent coatings as it enhances adhesion. During shot blasting, the surface is peened, but no material is actually removed.

- Vibratory Deburring: This method uses abrasive media in a vibrating machine to remove burrs, smooth sharp edges, and improve the overall surface smoothness, enhancing the consistency of part quality.

Chemical & Electrochemical Finishes: These treatments create a protective layer through chemical reactions.

- Anodizing: An electrochemical process used on aluminum parts that thickens the natural oxide layer on the surface. This creates a durable, corrosion-resistant, and wear-resistant finish that also provides better adhesion for paints and glues.

- Passivation / Chromate Conversion (Alodine): A chemical treatment that creates a protective conversion coating on aluminum and zinc parts. It acts as a corrosion inhibitor, a primer for paint, or a decorative finish while retaining electrical conductivity.

- Electroless Nickel Plating: This auto-catalytic process deposits a uniform layer of nickel-phosphorus alloy onto a part without using an electrical current. It provides excellent corrosion and wear resistance and is ideal for complex geometries because the coating is even, regardless of the part’s shape.

Coating Finishes: These involve applying a layer of another material to the surface.

- Powder Coating: A dry powder is applied electrostatically and then cured with heat to form a hard, durable finish that is tougher than conventional paint. It is available in many colors and textures and is widely used for both protective and decorative purposes.

- E-coating (Electrophoretic Coating): In this dip process, charged paint particles are attracted to the part via an electric current, resulting in a uniform and complete coating, even in hard-to-reach areas. It offers excellent adhesion and is often used as a primer followed by a powder coat for exterior applications.

- Painting: Liquid paint can be applied via spraying, brushing, or dipping to provide a decorative and protective layer. It offers a wide range of color options and is a versatile finishing choice.

- Cerakote: A ceramic-based finish that provides exceptional hardness, wear resistance, and corrosion protection. It is often used on high-quality metal surfaces like firearms.

- Physical Vapor Deposition (PVD): An advanced process where a thin film of metal is vaporized and deposited onto the part in a vacuum. PVD finishes are extremely durable and available in various colors but come at a higher cost.

Sealing Processes

- Impregnation: This process is used to seal the inherent porosity in die-cast parts. By filling the micro-pores with a sealant, impregnation prevents leaks in pressure-tight components and stops issues like outgassing or spotting that can ruin subsequent coating finishes.

Comparing Casting Processes: Die Casting vs. Other Methods

Die casting is a dominant manufacturing method, but it is part of a larger family of casting processes. The choice between them depends on factors like production volume, part size and complexity, material requirements, and budget. The primary difference between casting methods is often the material used to create the mold.

Table 4: Comparison of Major Casting Processes

| Process | Mold Type & Material | Key Characteristics | Best For |

| 高压压铸 | Reusable (Non-expendable) hardened steel die. | High pressure injection; extremely fast cycles; excellent finish and accuracy; high tooling cost. | High-volume production (10,000+ pieces) of small to medium-sized, complex non-ferrous parts (aluminum, zinc). |

| 砂型铸造 | Single-use (Expendable) sand mold. | Gravity pour; low tooling cost; slower cycles; rougher surface finish and lower accuracy. | Low-volume production (<500 pieces), prototypes, and very large parts; can cast both ferrous and non-ferrous metals. |

| Investment Casting (Lost-Wax) | Single-use (Expendable) ceramic shell created around a wax pattern. | Gravity pour; wax pattern is melted out; excellent for highly complex shapes and fine details; superior surface finish; can cast high-temp alloys (e.g., stainless steel). | Low to medium volume production of intricate parts where high precision and finish are critical, such as in aerospace and medical applications. |

| Permanent Mold Casting (Gravity Die Casting) | Reusable (Non-expendable) metal mold (steel or iron). | Gravity pour into a reusable mold; better finish and accuracy than sand casting; lower tooling cost than die casting. | Medium-volume production (500-15,000 pieces) of less complex parts than die casting; good for parts requiring pressure tightness. |

Why Choose Our Company for Die Casting Services?

When selecting a die casting partner, experience, technical capability, and a commitment to quality are paramount. We strive to be your most trusted die casting solution provider with the following advantages:

- Excellent Professional Qualifications & Rich Experience: We are ISO 9001 certified and have decades of industry experience serving leading clients in the automotive, electronics, and medical sectors. Our engineering team has a deep understanding of various alloy properties and complex mold design.

- Advanced Technology & One-Stop Service: We operate a full range of hot- and cold-chamber die casting machines from 88 to 2000 tons, capable of meeting your needs for parts of all sizes. We offer a complete service from mold design and manufacturing, die casting production, and CNC precision post-machining to various surface treatments, simplifying your supply chain.

- Flexible and Rapid Response Capability: We not only excel at handling large-volume orders in the millions but also provide rapid prototyping and small-batch production services to help you quickly validate designs during the product development phase. Our professional project management team ensures seamless communication, guaranteeing fast quotes and on-time delivery.

- Proven Success & Customer Trust: We have successfully delivered hundreds of millions of high-quality die-cast parts to numerous well-known brands, including precision automotive sensor housings, robust 5G communication equipment bases, and lightweight consumer electronics frames. Our track record demonstrates our ability to meet the most demanding technical challenges.