If you’re picking an aluminum die casting alloys for a new part, the smartest choice balances geometry, properties, finish, and cost. Here’s a plain-English guide—what the common alloys are, where they shine, and how to choose with confidence. Aluminum die casting alloys refer to an Al-based formulation (e.g., A380, A360, A413, ADC12, B390, 518) optimized for high-pressure die casting. Each balances castability, strength, corrosion resistance, pressure tightness, and finish to suit different applications.

Below you’ll find quick definitions, the short list of aluminum alloys, and a fast decision path grounded in NADCA guidance.

- What are the aluminum die casting alloys (and why not “pure” aluminum)?

- How to Pick the Right Aluminum Die Casting Alloy?

- Surface finishing Compatibility

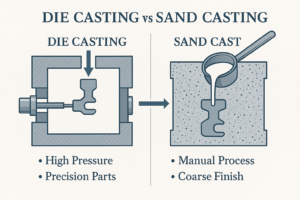

- Process Notes for High-Pressure Die Casting (HPDC)

- Which aluminum die casting materials Should You Choose?

- What Risks Should You Control?

- 常见问题

- 结论

- Aluminum Die Casting Services

What are the aluminum die casting alloys (and why not “pure” aluminum)?

Die casting alloys aren’t pure Al. They’re engineered mixes (Si, Cu, Mg, Fe, Mn, Zn, etc.) that fill thin walls fast, release from steel dies, and solidify soundly. Example: controlled iron additions (~0.6–1.2%) reduce die soldering and erosion, protecting the steel tool—one reason “die-cast” chemistries differ from wrought grades

Why this matters:

- Castability & thin walls. Silicon improves fluidity so metal reaches every rib and corner.

- Die life. Iron moderates aggressive attack on die steel.

- Downstream behavior. Copper, Mg, and Si tune strength, pressure tightness, and corrosion—trade-offs you’ll weigh when selecting

How to Pick the Right Aluminum Die Casting Alloy?

For Pressure-Tight Applications (e.g., Valve Bodies, Housings):

- Primary Choice: A413 / ADC14. Its excellent fluidity and pressure tightness make it ideal for leak-proof components.

- Note: While strong in sealing, its mechanical strength is lower than A380.

For Corrosion Resistance & Decorative Anodizing (e.g., Marine Parts, Architectural Hardware):

- Primary Choice: 518 / ADC5. Offers the best corrosion resistance and produces a high-quality, aesthetically pleasing finish after anodizing.

- Note: This alloy has a narrower casting window and can be more challenging to work with. Its use should be justified by critical finishing requirements.

For High Wear Resistance (e.g., Pistons, Cylinders, High-Friction Parts):

- Primary Choice: B390 / ADC14. The high silicon content provides exceptional hardness and wear resistance.

- Note: This comes at the cost of very low ductility (<1%). The part will be brittle, and post-casting machining is more difficult and costly.

For General Purpose & Cost-Effectiveness (e.g., Electronic Housings, Brackets):

- Primary Choice: A380 / ADC10 or 383 / ADC12. These are the industry workhorses, offering the best balance of cost, castability, and mechanical properties for a wide range of applications.

- Note: Their corrosion resistance is only fair, and they are not suitable for high-quality decorative anodizing (will result in a mottled gray finish).

To make an informed decision, you need both qualitative ratings and quantitative data. Here, we integrate NADCA’s industry-standard ratings with typical property values.

Table 1: Casting & Product Property Ratings (1 = Excellent, 5 = Poor)

| 财产 | A380 | A360 | A413 | B390 | 518 |

| Resistance to Hot Cracking | 2 | 2 | 1 | 3 | 5 |

| Die Filling Capacity (Fluidity) | 2 | 2 | 1 | 2 | 4 |

| Pressure Tightness | 2 | 1 | 1 | 2 | 3 |

| Resistance to Die Soldering | 3 | 2 | 2 | 1 | 5 |

| 耐腐蚀性 | 3 | 1 | 2 | 3 | 1 |

| 机械加工性能 | 2 | 2 | 3 | 4 | 2 |

| Anodizing (Decorative) | 5 | 4 | 4 | 5 | 1 |

| Polishability | 3 | 3 | 3 | 4 | 2 |

Table 2: Typical Mechanical & Chemical Properties (As-Cast)

| 财产 | A380 (ADC10) | A413 (ADC14) | B390 | 518 (ADC5) |

| Tensile Strength (MPa / ksi) | 324 / 47 | 290 / 42 | 280 / 41 | 290 / 42 |

| Yield Strength (MPa / ksi) | 160 / 23 | 145 / 21 | 240 / 35 | 190 / 28 |

| Elongation (% in 50mm) | 3.5 | 3.5 | <1 | 8.0 |

| Hardness (HB) | 80 | 80 | 120 | 75 |

| Key Alloying Elements | 7.5-9.5% Si, 2.0-3.0% Cu | 11.0-13.0% Si | 16.0-18.0% Si, 4.0-5.0% Cu | 7.5-8.5% Mg |

Tabel3: Global Grade Equivalency Chart

| USA (AA) | Japan (JIS) | Europe (EN AC) | Common Use |

| A380 | ADC10 | EN AC-46000 | General Purpose |

| 383 | ADC12 | EN AC-46100 | High-fluidity alternative to A380 |

| A413 | – | EN AC-44300 | Pressure Tightness |

| 518 | ADC5 | EN AC-51300 | Anodizing, Corrosion Resistance |

Surface finishing Compatibility

The alloy you choose determines the finishing options available. If you’re unfamiliar with common aluminum surface finishing processes, read our professional Aluminum Surface Finishing article—it explains anodizing, powder coating, plating, and more to help you choose the right finish for your part.

- A380 / 383 (ADC12): Due to high silicon content, the appearance after anodizing is generally poor and non-uniform (dark gray). They are, however, excellent candidates for powder coating, e-coating, and painting.

- 518 (ADC5): The low-silicon, high-magnesium composition makes this the ideal choice for decorative anodizing, producing a bright, clear finish.

- B390: Not suitable for anodizing. Due to its hardness, it is an excellent candidate for grinding and polishing to achieve a smooth, wear-resistant surface. It can also be chrome-plated.

Process Notes for High-Pressure Die Casting (HPDC)

Your alloy choice has direct consequences on the factory floor.

- Die Soldering & Iron Control: Alloys with low iron content are more prone to soldering (welding) to the steel die. For alloys like 518, precise control of die temperature, release agent application, and shot parameters is critical.

- Hot Cracking: Alloys with a wide freezing range, like 518, are more susceptible to hot cracking. This requires careful die design, including larger fillets, generous draft angles, and optimized cooling channels.

- Fluidity & Wall Thickness: The superior fluidity of high-silicon alloys like A413 allows for the casting of thinner walls and more intricate details compared to an alloy like 518.

Which aluminum die casting materials Should You Choose?

Four-step decision path

- Define performance targets – strength, corrosion resistance, and heat resistance.

- Assess geometry complexity – thin walls/ribs dictate higher fluidity requirements.

- Model cost vs. production scale – tooling, takt time, and total landed cost.

- Verify process fit – as-cast property route vs. heat-treat needs (e.g., T5), vacuum HPDC, leak-tightness testing.

What Risks Should You Control?

- Hot cracking (hot tearing).

Avoid high-zinc Al–Zn alloys for die casting. For Al–Si systems, keep Si in the ~7–12 wt% range to improve fluidity and reduce hot-tear risk (e.g., ADC12/A383 for thin-wall fill). - Porosity / gas entrapment.

In Al–Si alloys (e.g., A356 in gravity/permanent-mold, and Si-rich HPDC grades), optimize vacuum/venting, overflow design, and die temperature control. Consider T5 stabilizing age where applicable to improve dimensional stability after machining. - Stress corrosion cracking (SCC) in Al–Mg families.

Follow the alloy spec for Mg content and limit copper impurities (commonly ≤0.1 wt% in many U.S. specifications) to preserve corrosion resistance. Avoid thermal histories that sensitize the microstructure, and use protective finishing (e.g., anodizing, coatings) for chloride environments.

常见问题

A380 is the workhorse worldwide because it balances castability, properties, and cost; ADC12/A383 is a close “A380-class” option widely used in Asia.

A360 is typically cited for better corrosion and elevated-temperature behavior than A380; 518 targets corrosion-critical applications with low Cu.

Look at A413 and process aids (vacuum, impregnation, robust sealing faces).

Gas porosity from high-speed injection can blister during solution heat treatment; many HPDC parts use as-cast/T5.

结论

Choosing an aluminum die casting alloy isn’t about a single “best” metal—it’s about fit. Start from geometry and environment, then pick the alloy whose natural strengths (castability, tightness, corrosion, wear) align with the job. By identifying which properties matter most for your specific application, you’ll be able to determine the aluminum die casting alloy that fits best. For more details, visit our 压铸服务 page to learn about the solutions 铸模 provides.

Ready to get an expert opinion on your project? Contact our engineering team today for a free design review and quote. We’ll help you select the optimal alloy and ensure your part is designed for success from day one.

Have a CAD file ready? Upload it here for a confidential and complimentary DFM analysis from our experts.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.