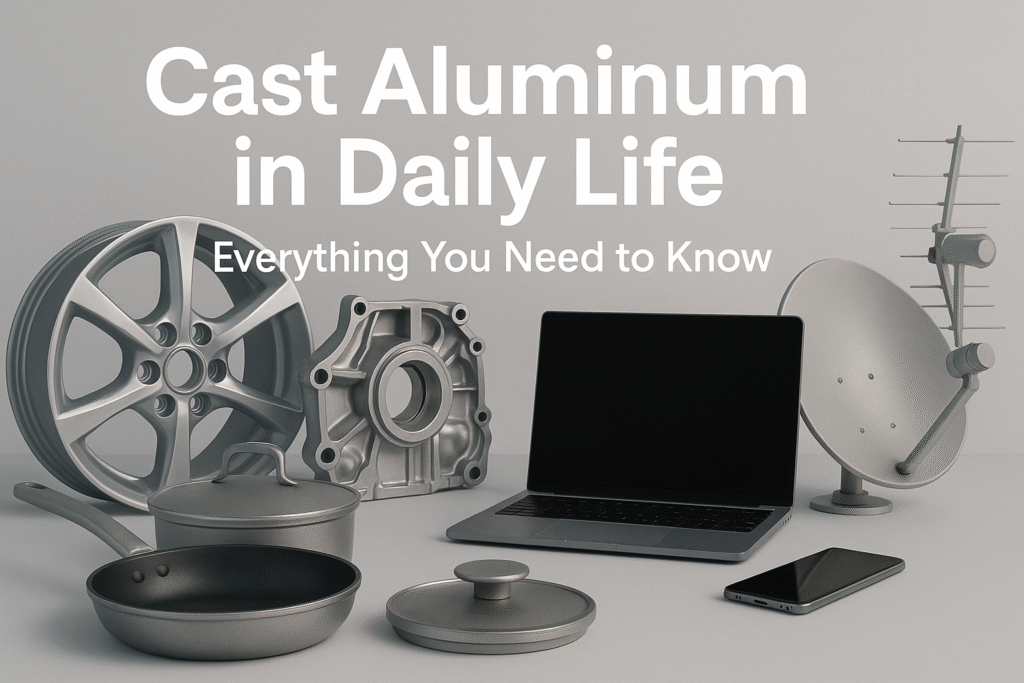

Hey there! Ever wonder about the stuff that makes up so many handy things around your house? I’ve been thinking a lot about cast aluminum lately – that tough, versatile material that pops up in more places than you might guess. Let’s dive into why it’s such a big deal, especially when it comes to what we use every day. You might be surprised by just how much you rely on it!

Cast aluminum is aluminum that’s been melted and poured into a mold to create a specific shape. It’s known for its durability, lightweight nature, and excellent corrosion resistance. You’ll find it in everything from cookware and car parts to the high-tech gadgets that power our digital world.

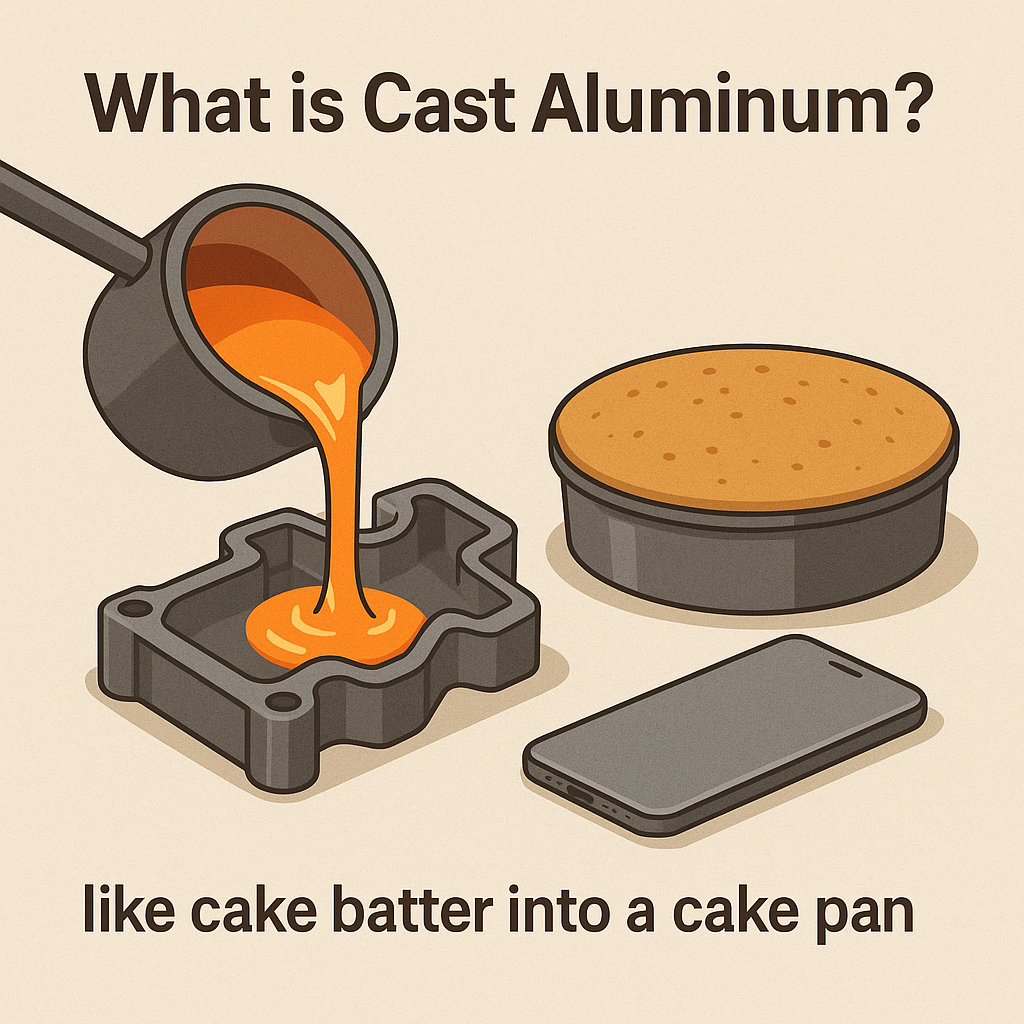

What is Cast Aluminum?

So, you hear the term “cast aluminum,” but what does it actually mean? Well, in simple terms, it’s aluminum that has gone through a process called casting. Think of it like making a cake – you have a liquid batter (molten aluminum in this case), and you pour it into a mold to give it a specific shape. Once it cools and solidifies, you have your final product.

The cool thing about casting is that it allows for the creation of complex shapes and designs that might be difficult or even impossible to achieve with other manufacturing methods, like simply bending or cutting sheets of aluminum. This is why cast aluminum is used for such a wide variety of products, from intricate decorative pieces to the high-performance components we’ll be talking about shortly.

Is Cast Aluminum Safe?

Now, I know what some of you might be thinking: “Is aluminum safe to use, especially in things I eat or drink from?” That’s a totally valid question! There’s been some chatter over the years about aluminum and its potential health effects. However, the general consensus among scientists and health organizations is that aluminum is safe for everyday use in the vast majority of applications. The amount of aluminum our bodies might absorb from consumer products is generally very low and not considered harmful by major health bodies.

Pure aluminum can react with acidic foods, but modern cast aluminum products typically feature protective coatings like non-stick layers or anodized finishes, significantly mitigating health risks. The World Health Organization (WHO) considers aluminum intake below 1 mg/kg body weight per week to be safe.

Is Cast Aluminum Cookware Safe?

Cast aluminum cookware is safe when coated. Uncoated aluminum can react with acidic foods like tomatoes or citrus, potentially introducing tiny aluminum traces into your meals. However, the U.S. Food and Drug Administration (FDA) confirms that typical aluminum exposure from cookware is within safe limits for consumers.

Cast Aluminum Cookware in Your Kitchen: Pros & Cons

Pros:

- Lightweight, easy to handle

- Excellent heat conductivity ensures even cooking

- Durable with proper care

- Usually more affordable compared to cast iron or stainless steel

Cons:

- Uncoated aluminum may react with acidic foods

- Susceptible to scratches if non-stick coating isn’t maintained properly

- Requires careful maintenance of non-stick surfaces

Cast Aluminum vs. Cast Iron: A Tale of Two Kitchen Metals

Let’s quickly compare cast aluminum with another popular casting material: cast iron. Both have their fans, and the best choice really depends on what you value in the kitchen.

| Özellik | Cast Aluminum | Cast Iron |

| Weight | Lighter and easier to handle. | Heavier, providing a very stable base. |

| Heat Distribution | Heats up quickly and evenly. | Takes longer to heat but retains it incredibly well. |

| Maintenance | Easier, often dishwasher safe (check first!). | Requires seasoning to prevent rust. |

| Durability | Good, but can warp at extreme temps. | Extremely durable, can last for generations |

If you want something lightweight that heats fast, cast aluminum is fantastic. If you prioritize superior heat retention for that perfect sear and don’t mind the heft, cast iron is a classic for a reason. I personally use both!

Cast Aluminum Powering Our Modern World

Alright, let’s move beyond the kitchen and patio furniture. The real magic of cast aluminum is in its industrial applications. This is where its unique combination of properties—lightweight, strong, corrosion-resistant, and an amazing heat conductor—makes it an indispensable material.

The Automotive Industry – Lighter, Faster, Greener

If you own a car, you’re almost certainly benefiting from cast aluminum. The auto industry is obsessed with “lightweighting,” which is the process of making vehicles lighter to improve fuel efficiency (or battery range in EVs) and handling. Aluminum is about one-third the weight of steel, making it a superstar in this area.

You’ll find it in critical components like:

- Engine Blocks and Cylinder Heads: Traditionally made of heavy iron, many modern engines now use cast aluminum blocks. They are strong enough to handle the immense pressures of combustion but slash a huge amount of weight from the vehicle.

- Transmission Housings: These are complex parts that need to be strong and dissipate heat effectively. Cast aluminum is perfect for this, as it can be molded into the intricate shapes needed while helping to keep the transmission fluid cool.

- Suspension Components: Parts like control arms and knuckles are increasingly made from cast aluminum. This reduces “unsprung weight” (the weight not supported by the suspension), which allows the wheels to react to bumps more quickly, improving ride quality and handling.

- Tekerlekler: “Alloy wheels” are typically made of cast aluminum. They look great, are lighter than steel wheels, and can help dissipate heat from the brakes.

The Telecommunications Sector – Keeping Us Connected

Ever wonder what a 5G base station—those boxes you see on towers and buildings—is made of? There’s a good chance its housing is die-cast aluminum. In telecommunications, reliability is everything. Equipment is often placed outdoors, exposed to rain, wind, and sun for years.

Here’s why cast aluminum is the go-to choice:

- Heat Dissipation: High-powered electronics, like those in a 5G base station, generate a ton of heat. Aluminum is an excellent thermal conductor. The housing itself acts as a giant heat sink, drawing heat away from the sensitive internal components and radiating it into the air, preventing overheating and ensuring the network stays online.

- Durability and Corrosion Resistance: Aluminum naturally forms a protective oxide layer that makes it highly resistant to rust and corrosion, which is essential for equipment that needs to operate for a decade or more in harsh weather.

- EMI Shielding: This is a big one. All those electronic signals can interfere with each other. A properly designed metal enclosure, like one made from die-cast aluminum, provides excellent Electromagnetic Interference (EMI) shielding. It acts like a cage, keeping the internal signals in and unwanted external signals out, which is crucial for clear and fast data transmission.

Tüketici Elektroniği – The Premium Feel in Your Hands

Think about your high-end laptop, your tablet, or maybe that premium pair of headphones. The sleek, cool-to-the-touch metal body is often made from—you guessed it—cast aluminum. In a market driven by aesthetics and user experience, cast aluminum delivers on multiple fronts.

Here’s how it enhances the gadgets we use every day:

- Aesthetics and Premium Feel: Let’s be honest, a precision-molded aluminum chassis just feels more premium and durable than plastic. It allows for sleek, minimalist designs with sharp lines and a high-quality finish that consumers love.

- Strength and Portability: We want our devices to be thin and light, but we also don’t want them to bend or break in our backpacks. Cast aluminum provides an excellent strength-to-weight ratio, allowing for thin yet rigid structures that protect the delicate electronics inside.

- Heat Management: Just like in telecom equipment, our powerful, multi-core processors in laptops and tablets generate heat. The aluminum body of the device often plays a key role in the thermal management system, helping to spread and dissipate heat to keep the device running at peak performance.

Common Cast Aluminum Manufacturing Processes

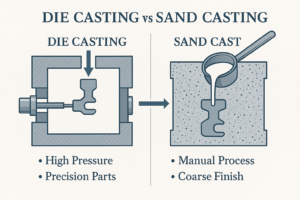

Die Casting (High-Pressure Die Casting – HPDC)

Molten aluminum is injected under high pressure into steel molds, ideal for mass production of detailed, high-quality parts. It accounts for approximately 58% of aluminum casting production due to its efficiency and precision.

Gravity Casting

Molten aluminum is poured into molds by gravity alone, suitable for thicker, simpler components. Often used for automotive cylinder heads and large, robust parts.

Kum Döküm

Flexible and economical, sand casting uses sand molds to create large or uniquely shaped aluminum parts. It’s a popular choice for small to medium batch sizes, constituting around 25% of aluminum castings.

The Driving Force Behind Modern Manufacturing

And that brings us right back to what we live and breathe at CastMold. We are specialists in high-pressure aluminum die casting, and it’s the preferred method for nearly all the industrial examples we just talked about.

Why is it the driving force? Because die casting is all about precision, speed, and consistency.

- Bu high pressure forces the metal into every tiny nook and cranny of the mold, creating incredibly detailed parts with net-shape or near-net-shape accuracy. This means the part comes out of the mold very close to its final form, minimizing the need for costly and time-consuming secondary machining.

- Bu steel dies are extremely durable and can be used to produce hundreds of thousands of identical parts, making it a highly efficient and cost-effective process for mass production.

- Bu rapid cooling process results in a fine-grained microstructure in the aluminum, which enhances its mechanical strength.

When a client comes to us with a design for a new automotive component, a 5G housing, or a laptop chassis, we use our expertise in aluminum die casting to turn that complex digital design into a tangible, high-performance physical part. It’s incredibly rewarding to be a part of that process, knowing that the components we help create are making our cars safer, our networks faster, and our favorite gadgets more durable and beautiful.

Why choose us?

At our company, we specialize in aluminum die casting, offering precision, efficiency, and versatility. Whether you need cookware, electronic housings, or automotive components, we deliver small-batch customization, rapid prototyping, and ISO-certified quality assurance

- Precision accuracy (tolerances up to ±0.02mm)

- Flexible MOQ starting from just 500 pieces

- Fast sampling and turnaround

- Full-service support: mold design, casting, CNC machining, and surface finishing

Cast aluminum enriches our daily lives through versatility, safety, and practicality. Have you thought about how aluminum die casting can boost your next project? Reach out today, and let’s discuss the possibilities!