For most metal components, the story does not end after casting or machining.To achieve stable quality, corrosion resistance and a professional appearance, you need surface finishing processes that match the material and working environment.

This article gives product designers and project engineers a clear, practical overview of the most common surface finishing processes used on metal parts – especially aluminum and zinc die castings – and how to choose between them for your next project.

- 1.Why Surface Finishing Processes Matter for Metal Parts

- 2.Pre-treatment – The Foundation of Any Surface Finishing Process

- 3. Electroplating and Electroless Plating

- 4. Anodizing and Conversion Coatings for Aluminum

- 5. Organic Coatings: Painting, Powder Coating & E-Coat

- 6. Mechanical Surface Strengthening: Shot Blasting & Shot Peening

- 7. Surface Hardening Treatments

- 8. How to Choose the Right Surface Finishing Process

- 9. Design Tips for Die-Cast and Machined Parts with Surface Finishing

- 10. From Design to Delivery: How Cast Mold Supports Surface Finishing

- Aluminum Die Casting Services

1.Why Surface Finishing Processes Matter for Metal Parts

- Corrosion protection – protect steel, aluminum and zinc alloys from rust, oxidation and chemical attack.

- Wear resistance – improve hardness and reduce abrasion on sliding or contact surfaces.

- Appearance & branding – deliver consistent color, gloss and texture that match your product design language.

- Functional performance – control friction, conductivity, solderability, paint adhesion, bonding performance, etc.

In real projects, you are usually balancing all four at the same time.

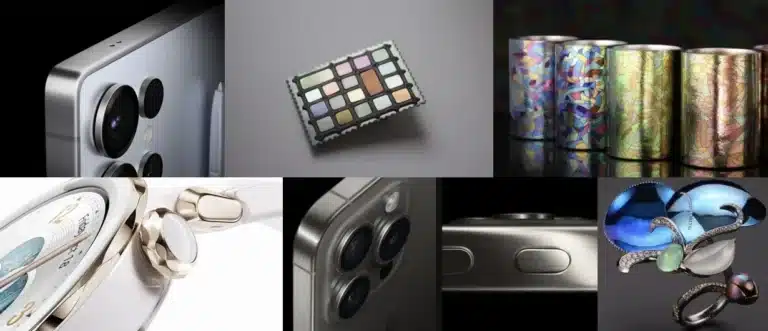

Special Applications of Surface Treatment

Beyond protection and decoration, electroplating can also be used to obtain many special functions.

For example:

- Gold plating on semiconductor devices can achieve very low contact resistance;

- Plating an aluminum–tin alloy on electronic components can provide excellent solderability;

- Hard chrome plating on piston rings and shafts can provide very high wear resistance;

- The oxidation (anodizing) and coloring of aluminum and aluminum alloys are used not only on lighters, harmonicas, fountain pens, metal vacuum flasks and small hardware parts, but have also expanded to architectural materials such as door and window frames and display counter frames in high-end hotels, as well as kitchenware, all of which often use anodized aluminum components;

- In the machinery industry, iron electroplating is used to repair locomotive and automobile crankshafts, bringing significant economic benefits.

2.Pre-treatment – The Foundation of Any Surface Finishing Process

No surface finishing process will perform well on a dirty or oxidized surface. The pretreatment process mainly includes four different steps: polishing, degreasing, derusting, and activation

2.1 Mechanical finishing & polishing

Typical mechanical pre-treatments include:

- Grinding & deburring – remove sharp edges, flashes and machining marks.

- Mechanical polishing / buffing – improve gloss and smoothness for decorative surfaces.

- Vibratory / barrel finishing – use stones or media to remove burrs and refine the surface on batches of small parts.

- Shot blasting / sand blasting – clean the surface, unify roughness and create an anchor profile for later coatings.

These steps correct defects from casting or machining and prepare a uniform baseline for further surface finishing processes.

2.2 Cleaning & degreasing

Oils, cutting fluids and fingerprints will seriously reduce coating adhesion. Common methods:

- Solvent cleaning – remove oils and low-viscosity contaminants.

- Alkaline degreasing – chemical cleaning in alkaline solution to remove heavy oils and dirt.

- Ultrasonic cleaning – combine chemistry and ultrasonic agitation for complex geometries.

After cleaning, parts are usually rinsed with de-ionized water to avoid stains.

2.3 Chemical conversion layers (phosphating, chromating)

For steel parts, phosphating creates a micro-crystalline phosphate layer that improves paint adhesion and basic corrosion resistance.

For aluminum and zinc, chromate or other conversion coatings are used to enhance corrosion resistance and as a base for painting or powder coating.

3. Electroplating and Electroless Plating

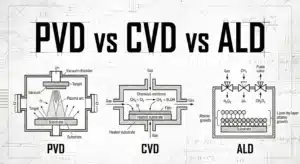

Electroplating uses DC current to deposit a metallic coating on the part surface. The training slides classify different plating types by coating material and function, such as zinc, nickel, chrome, copper and tin.

3.1 Zinc plating

- Main function: sacrificial corrosion protection for steel parts.

- Typical finishes: blue-white, yellow, black passivation.

- Usage: fasteners, brackets, small functional components that require low to medium corrosion resistance at low cost.

3.2 Nickel & chrome plating

- Nickel plating:

- Provides brightness, moderate hardness and corrosion resistance.

- Often used as an under-layer for chrome or decorative finishes.

- Chrome plating:

- Very hard, wear-resistant and glossy.

- Common for handles, decorative trims and parts that need a mirror-like appearance.

3.3 Copper & tin plating

- Copper plating: improves conductivity and acts as an intermediate layer to improve adhesion on difficult substrates.

- Tin plating: widely used on electrical connectors to improve solderability and contact performance.

3.4 Electroless nickel plating (ENP)

Electroless plating does not rely on external current. Instead, chemical reduction reactions deposit a very uniform coating even on complex shapes and deep cavities.

- Uniform thickness, good wear and corrosion resistance.

- Common for precision components, valves and high-reliability parts.

4. Anodizing and Conversion Coatings for Aluminum

The aluminum anodizing is one of the most common surface finishing processes for aluminum alloys.

4.1 Decorative anodizing

- Forms a controlled oxide layer on aluminum in an electrolyte under DC current.

- Pores in the oxide layer can be dyed in different colors, then sealed.

- Features: good corrosion resistance, UV stability and high-end appearance.

Note: for typical high-pressure die casting alloys such as ADC12 / A380, the high silicon content can lead to uneven decorative anodizing. These alloys are usually better suited for powder coating, painting or e-coat rather than bright anodized finishes.

4.2 Hard anodizing

- Thicker and harder oxide layer than decorative anodizing.

- Greatly improves wear resistance and thermal resistance.

- Common for sliding parts, cylinders and components in harsh environments.

4.3 Chromate conversion coatings

- Thin conversion films on aluminum to enhance corrosion resistance and electrical continuity.

- Often used as an under-layer for paint or powder coating on castings and extrusions.

5. Organic Coatings: Painting, Powder Coating & E-Coat

The organic surface finishing processes such as wet painting, powder coating and electrophoretic coating (e-coat).

5.1 Wet painting

- Liquid paints (solvent- or water-based) sprayed onto the part and cured.

- Very flexible in color and gloss; suitable for small batches and complex color matching.

- Requires controlled film thickness and good pre-treatment for adhesion.

5.2 Powder coating

- Solid powder (typically epoxy, polyester or hybrid) is electrostatically sprayed, then cured at high temperature.

- Produces a thick, tough coating with excellent corrosion resistance and impact strength.

- Ideal for aluminum and zinc die castings, housings, brackets and covers.

For many HPDC parts (ADC12 / A380), powder coating is the most robust combo of cost, corrosion resistance and visual stability.

5.3 Electrophoretic coating (E-coat)

- Parts are immersed in a paint bath and voltage is applied to deposit a thin, uniform coating.

- Very good coverage on complex geometries and inner cavities.

- Often used as a primer under powder coating or as a thin, high-corrosion-resistance finish on its own (common in automotive industry).

6. Mechanical Surface Strengthening: Shot Blasting & Shot Peening

The slides distinguish cleaning blasting from shot peening: both use high-speed media, but with different goals.

- Shot blasting / sand blasting

- Remove scale, rust, loose particles and casting skin.

- Create a uniform, matte texture and controlled roughness (Ra).

- Prepare the surface for painting, powder coating or plating.

- Shot peening

- Intentionally bombards the surface with controlled shot to create compressive residual stress.

- Improves fatigue strength and resistance to crack initiation on springs, gears and structural components.

7. Surface Hardening Treatments

S urface hardening processes like carburizing, nitriding and induction hardening.

- Carburizing – increase carbon content in the surface of low-carbon steel, then quench to form a hard case with a tough core.

- Nitriding – diffuse nitrogen into steel at relatively low temperature to create a very hard, wear-resistant layer with minimal distortion.

- Induction / flame hardening – rapidly heat the surface and quench it for localized hardening on gear teeth, shafts, etc.

These treatments are not “coatings” in the traditional sense but are critical surface engineering processes when wear and fatigue performance are key.

8. How to Choose the Right Surface Finishing Process

When selecting surface finishing processes for metal parts, consider:

- Base material

- Aluminum / zinc die castings vs. steel vs. copper alloys.

- Some finishes are material-specific (e.g., anodizing for aluminum, black oxide for steel).

- Working environment

- Indoor vs. outdoor, marine or chemical exposure, temperature, humidity.

- Define target salt spray hours or specific corrosion standards early.

- Functional requirements

- Wear resistance, friction coefficient, conductivity, insulation, solderability, etc.

- Cosmetic level

- Is it a hidden internal part or a visible customer-facing surface?

- Required gloss (matte / satin / gloss), texture and color tolerance.

- Geometry and thickness

- Deep pockets, sharp edges and non-uniform wall thickness can cause uneven coating or burning in plating/anodizing.

- Complex parts may benefit from powder coating or e-coat instead of highly decorative plating.

- Cost, volume and repairability

- Powder coating and e-coat are efficient for mass production.

- Wet painting can be flexible for small batches and color changes.

- Some finishes are easy to rework; others are not.

9. Design Tips for Die-Cast and Machined Parts with Surface Finishing

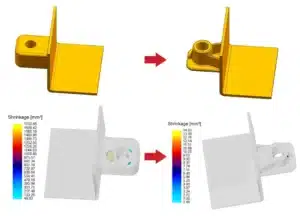

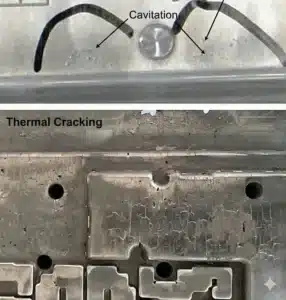

To make surface finishing processes more stable and predictable:

- Avoid sharp corners and knife edges – add fillets so coatings do not become too thin or burn at edges.

- Keep wall thickness as uniform as possible – reduces porosity and improves coating adhesion on die castings.

- Define masked areas clearly – threads, sealing surfaces, grounding points, etc., should be marked on drawings.

- Specify roughness and coating thickness – e.g., Ra 1.6–3.2 µm, powder coating 60–80 µm, anodizing thickness 10–25 µm, etc.

- Plan inspection methods – color standards, gloss, thickness gauges, adhesion tests, salt-spray requirements.

Thinking about surface finishing processes at the design stage avoids expensive redesign and trial-and-error later in the project.

10. From Design to Delivery: How Cast Mold Supports Surface Finishing

At Cast Mold, surface finishing is treated as part of the complete project engineering, not just a final “color” step.

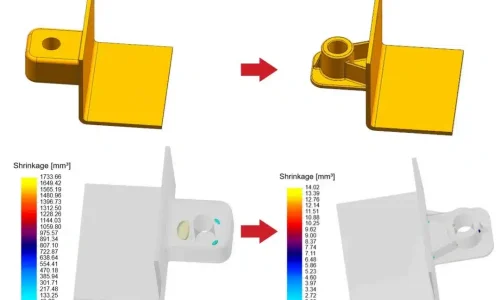

- We review DFM and Moldflow results together with your surface requirements to minimize casting defects that may affect finishing (porosity, cold shuts, weld lines).

- For aluminum and zinc HPDC parts, our team can recommend the most suitable surface finishing processes – such as powder coating, e-coat, painting or plating – based on alloy, geometry and performance targets.

- During sampling, we coordinate with qualified finishing partners to run trial runs, adhesion tests and salt-spray tests so you see the real final effect, not just the raw casting.

- From prototype to mass production, we focus on “precision from design to delivery”, ensuring that mold design, casting parameters and surface finishing are all aligned with your specification.

If you plan a new die casting or machining project and are not sure which surface finishing process to choose, you can treat this guide as a quick checklist—and then discuss your specific case with our engineering team for a tailored recommendation.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.