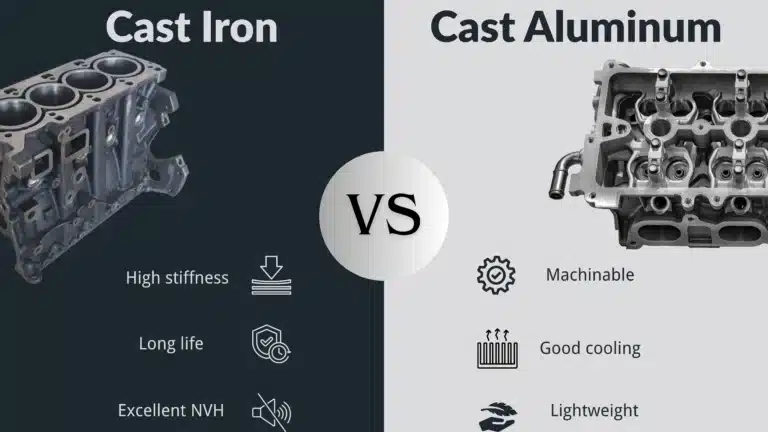

Choosing the right material for a critical component like an engine block or a high-load industrial part is a decision with far-reaching consequences. For decades, the debate between cast aluminum vs cast iron has been central to automotive and industrial engineering. While aluminum is often touted for its light weight, is it always the superior choice? Conversely, does cast iron’s traditional reputation for strength hold it back in modern, efficient designs?

This guide cuts through the noise. We will provide a practical, in-depth comparison from a manufacturing perspective, covering not just the material properties but also the realities of production, machining, and total cost of ownership. Whether you’re designing a next-generation engine, a robust pump housing, or a complex electronic enclosure, this article will help you make an informed decision.

- Quick Comparison Table: Cast Aluminum vs Cast Iron at a Glance

- What Is Cast Aluminum? (HPDC Focus)

- What Is Cast Iron?

- Engine Blocks—Where the Trade-offs Really Show

- Manufacturing & Machining Reality (Cost, Tooling, Yield)

- NVH, Stiffness & Reliability

- Cost & Platform Strategy (Why OEMs Choose What They Choose)

- Beyond Engine Blocks—Other Industrial Parts

- How to Choose (Decision Matrix)

- Recommended Specs & Tolerances (Procurement Checklist)

- FAQs

- Work With Cast Mold

- Aluminum Die Casting Services

Quick Comparison Table: Cast Aluminum vs Cast Iron at a Glance

For engineers and purchasing managers who need a fast answer, this table summarizes the key differences.

| Feature | Cast Aluminum | Cast Iron |

| Density / Weight | Significantly lighter, excellent for weight reduction. | Approx. 3 times heavier, weight savings are minimal. |

| Stiffness & Pressure | Lower stiffness; often requires structural reinforcement. | High stiffness and compressive strength, ideal for high pressure. |

| Thermal Expansion | High coefficient; sensitive to temperature changes. | Low coefficient; dimensionally stable under thermal stress. |

| Thermal Conductivity | Excellent; dissipates heat quickly. | Good, but lower than aluminum. |

| Wear & Durability | Lower intrinsic wear resistance; requires liners/coatings. | Excellent inherent wear resistance and durability. |

| Machinability | Softer but challenging (chip control, tool wear). | Harder but predictable and consistent to machine. |

| Overall Cost | Material is cheaper, but manufacturing can be more expensive. | Material is more expensive, but machining is often simpler. |

| Common Application | Engine blocks, housings, heat sinks, electronic parts. | High-load engine blocks, pump bodies, machine bases. |

What Is Cast Aluminum? (HPDC Focus)

Cast aluminum refers to a range of alloys that are melted and injected into a mold to create a near-net-shape part. At CastMold, we specialize in High-Pressure Die Casting (HPDC), a process ideal for producing complex, thin-walled components with excellent surface finish and dimensional accuracy.

Common alloys we work with include:

- A380/ADC12: The workhorse of aluminum die casting, offering a great combination of mechanical properties and castability.

- A356-T6: Known for its superior strength and ductility, often used in structural parts that require heat treatment.

- AlSi12: An alloy with high silicon content, providing excellent fluidity for intricate and thin-walled designs.

A key consideration for aluminum engine blocks is the design of the cylinder bores. Due to aluminum’s lower wear resistance, a protective layer is necessary. This leads to two primary approaches:

- Iron Cylinder Liners: A traditional and robust solution where a cast iron sleeve is inserted into the aluminum block. This provides a durable wear surface but adds weight and complexity.

- Sprayed Coatings (Plasma/Arc Spray): A modern alternative where a very thin, hard layer of steel is sprayed directly onto the cylinder walls. This technology, like Plasma Transferred Wire Arc (PTWA), reduces weight but requires stringent process control to ensure long-term durability.

Aluminum blocks often feature an “open-deck” design, where the areas around the top of the cylinders are open to the surrounding water jacket. This simplifies the casting process and improves cooling efficiency, but it offers less cylinder bore rigidity compared to a closed-deck design.

What Is Cast Iron?

Cast iron, particularly gray and ductile iron, has been a cornerstone of industrial manufacturing for centuries. Its reputation is built on a foundation of immense strength, excellent vibration damping (high hysteresis), and superior wear resistance.

These properties make cast iron the material of choice for applications demanding extreme durability and stability. In engine design, this translates to a natural suitability for “closed-deck” blocks. A closed-deck design provides maximum structural support around the top of the cylinders, making the block exceptionally rigid and resistant to the high combustion pressures found in high-performance and turbocharged engines. This is why many in the aftermarket and racing communities prefer cast iron blocks—they can withstand enormous boost pressures and repeated thermal cycles without distortion.

Engine Blocks—Where the Trade-offs Really Show

The engine block is the perfect case study to explore the nuanced trade-offs between cast aluminum and cast iron.

Weight vs. Real-World Benefit

While an aluminum block is significantly lighter than its iron counterpart, the real-world benefit depends on the application. For a large V8 or V12 engine, the weight savings are substantial and directly impact vehicle dynamics and fuel efficiency. However, for a smaller 3 or 4-cylinder engine, the percentage of total vehicle weight saved is much smaller. In these cases, the added cost and complexity of aluminum may not deliver a proportional performance benefit. The “lighter is always better” mantra doesn’t apply universally.

Durability & Wear (Liners vs. Sprayed Coatings)

The move from iron liners to sprayed coatings is a key enabler for lightweighting aluminum engines. However, this technology comes with its own set of challenges. In small-displacement, high-revving engines, vibrations and piston side-loads are more pronounced. If the coating process is not perfectly controlled, or if the engine operates outside its designed parameters, the risk of premature wear or coating delamination increases. For high-end, lower-revving engines, the process window is wider, and these coatings have proven to be very reliable.

Thermal Management Is a System, Not a Patch

Aluminum’s high thermal conductivity is an advantage, but it must be managed within a complete system. The engine’s cooling channels, oil passages, temperature sensors, and electronic control unit (ECU) are all calibrated to work with the block’s specific thermal behavior. This is why simply retrofitting an aluminum block with aftermarket iron liners is a bad idea—it can disrupt the carefully balanced heat transfer, leading to hot spots, incorrect sensor readings, and potential engine failure.

Open Deck vs. Closed Deck

The choice between an open-deck and closed-deck design is a classic engineering trade-off between manufacturability and ultimate strength.

- Open-Deck (Common in Aluminum): Easier to die-cast, promoting better yield rates and cooling. It is perfectly adequate for the vast majority of production vehicles.

- Closed-Deck (Common in Cast Iron): Offers superior cylinder rigidity and head gasket sealing under very high pressure. It is the preferred choice for high-boost, high-performance applications.

Manufacturing & Machining Reality (Cost, Tooling, Yield)

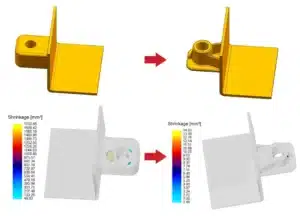

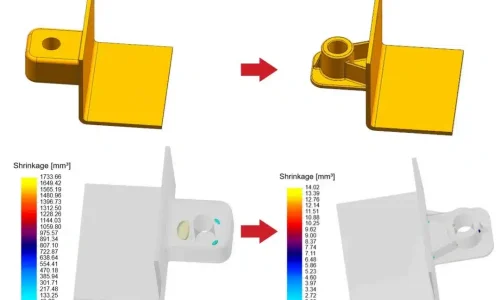

A common misconception is that because aluminum is a cheaper raw material, an aluminum part is always cheaper to produce. The reality is far more complex.

- High Thermal Expansion: Aluminum expands and contracts significantly more than iron with temperature changes. This means machining tolerances must be tightly controlled in a climate-controlled environment to ensure final dimensions are accurate.

- Challenging Chip Control: Aluminum’s ductility makes it “gummy.” During machining, chips tend to be long and stringy, which can wrap around tooling, cause surface defects, and halt production. Specialized chip breakers and high-pressure coolant are required.

- Tooling Costs: While softer, aluminum can be abrasive, especially high-silicon alloys. It requires expensive polycrystalline diamond (PCD) or coated carbide tools to achieve acceptable tool life and production speeds, increasing the overall manufacturing cost.

Sometimes, a component is “cheaper by material but more expensive to manufacture.” At CastMold, our DFM (Design for Manufacturability) analysis helps clients foresee these challenges and optimize their designs for cost-effective production in either material.

NVH, Stiffness & Reliability

Noise, Vibration, and Harshness (NVH) is a critical factor in modern vehicle design. Cast iron’s inherent mass and excellent damping properties naturally absorb engine vibrations, leading to a quieter and smoother operation. Aluminum, being stiffer and lighter, tends to transmit more noise and vibration. Engineers compensate for this by adding structural ribs, localized reinforcements, and sophisticated engine mounting systems, but it adds complexity to the design.

Cost & Platform Strategy (Why OEMs Choose What They Choose)

Original Equipment Manufacturers (OEMs) often make material decisions based on a platform strategy. A high-end engine platform might be designed with an aluminum block that can be adapted for various luxury models. The high development cost is amortized across these premium vehicles.

Conversely, for a high-volume, cost-sensitive vehicle line, a proven cast iron block may be the most logical choice. It delivers the required durability and performance at a lower manufacturing cost without the need for an “aluminum for aluminum’s sake” marketing claim. The choice is driven by brand positioning, target cost, and the expected lifecycle of the vehicle.

Beyond Engine Blocks—Other Industrial Parts

The same principles apply to a wide range of industrial components.

- Cast Aluminum’s Strengths: Its light weight and excellent thermal conductivity make it ideal for:

- Electronics & Telecom Housings: Where heat dissipation and EMI shielding are critical.

- Heat Sinks: Maximizing surface area for efficient cooling.

- Automotive Parts: Such as transmission cases and oil pans.

- (Placeholder for CastMold case studies/images of our high-quality aluminum castings)

- Cast Iron’s Strengths: Its stiffness, durability, and pressure resistance make it the top choice for:

- Pump & Valve Bodies: Containing high-pressure fluids without distortion.

- Heavy Machinery Bases: Providing a stable, vibration-damping foundation.

- Industrial Gearboxes: Ensuring precise alignment under heavy torque.

How to Choose (Decision Matrix)

Use this matrix to guide your initial selection process.

| High Priority: Lightweight | High Priority: Durability / Stability | |

| High Load/Pressure | Aluminum (with reinforcement/coatings) | Cast Iron (Clear Winner) |

| Low Load/Pressure | Aluminum (Clear Winner) | Cast Iron (Potentially over-engineered) |

Consider these situational questions:

- Load: Will the part experience high, cyclical, or impact loads? (→ Cast Iron)

- Thermal Management: Is rapid heat dissipation key, or is dimensional stability under heat more important? (Rapid Cooling → Al; Stability → CI)

- Longevity: Is the target life over 10,000 hours or for extreme-mileage applications? (→ Cast Iron)

- Complexity: Is the design complex and thin-walled? (→ HPDC Aluminum)

- Total Cost: Have you evaluated machining, tooling, and yield costs, not just material price?

- Sustainability: What are the requirements for recyclability or remanufacturing?

Recommended Specs & Tolerances (Procurement Checklist)

When you send out an RFQ, be prepared to provide the following to ensure an accurate quote and a reliable part:

- Expected operational loads, pressures, and thermal cycles.

- Required block/water jacket design (open/closed deck).

- Specified cylinder wear surface solution (liner/coating).

- Key dimensional tolerances and GD&T for critical features.

- Machining plan, including required tooling and inspection protocols.

- Validation plan (bench testing, real-world trials) and PPAP requirements.

FAQs

Work With Cast Mold

Precision from design to delivery. The choice between cast aluminum and cast iron is complex, with implications spanning from initial DFM analysis to final production quality. At CastMold, we are more than just a supplier; we are your technical partner.

Our expertise covers the entire one-stop process:

- DFM and Material Selection

- In-house Mold Design and Manufacturing

- High-Pressure Die Casting (HPDC) of Aluminum & Zinc Alloys

- Precision CNC Machining

- A full suite of Surface Finishing options

If you are looking for a reliable die casting partner for your next project, contact us today for a free quote and design review. Let’s build something great together.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.