For components destined for harsh, unforgiving environments, material selection is not just a choice—it’s a critical decision that dictates product lifespan and reliability. While many aluminum alloys offer a balance of properties, when superior corrosion resistance is non-negotiable, A360 aluminum alloy emerges as the undisputed champion. It’s engineered from the ground up to withstand moisture, salt, and chemical exposure that would compromise lesser materials.

This guide will break down the science behind A360’s exceptional durability, compare it directly to the common A380 alloy, and demonstrate why it is the best choice for your most demanding high-pressure die casting (HPDC) applications.

- What is A360 Aluminum Alloy?

- Chemical Composition of A360 Aluminum

- Key Properties of A360 Aluminum

- A360 vs. A380: Which Alloy Should You Choose?

- When to Specify A360 Over A380

- Common Applications of A360 Aluminum Alloy

- Die Casting with A360: Process & Tooling Considerations

- Surface Finishing: Maximizing A360's Durability

- FAQs

- Aluminum Die Casting Services

What is A360 Aluminum Alloy?

A360 is an aluminum-silicon (Al-Si) alloy known for its exceptional pressure tightness, high strength at elevated temperatures, and superior corrosion resistance. As a die casting alloy, it offers excellent fluidity, allowing for the creation of intricate, thin-walled parts. Its composition is carefully controlled to maximize these desirable traits, making it a reliable choice for robust components in harsh environments.

The exceptional performance of A360 isn’t magic; it’s metallurgy. Its properties are a direct result of a carefully controlled composition designed for resilience. The two most critical elements are its low copper and high silicon content.

- Low Copper ( <0.6% ): This is the key to A360’s corrosion armor. In aluminum alloys, higher copper content creates microscopic galvanic cells within the metal’s structure, which act as focal points for corrosion to begin and accelerate. By strictly limiting copper, A360 eliminates this inherent weakness, making it far more stable in corrosive environments.

- High Silicon (9.0-10.0%): This enhances the alloy’s fluidity during casting, allowing it to fill complex, thin-walled molds with precision. This results in dense, pressure-tight castings that are less susceptible to internal porosity, further bolstering their resistance to environmental ingress.

| Element | Content (%) |

| Silicon (Si) | 9.0 – 10.0 |

| Magnesium (Mg) | 0.40 – 0.6 |

| Iron (Fe) | ≤1.3 |

| Copper (Cu) | ≤0.6 |

| Manganese (Mn) | ≤0.35 |

| Zinc (Zn) | ≤0.50 |

| Nickel (Ni) | ≤0.50 |

| Aluminum (Al) | Remainder |

Key Properties of A360 Aluminum

A360’s balanced properties make it a versatile material for a wide range of engineering applications.

Mechanical Properties

In its as-cast state, A360 provides a good balance of strength and hardness. It’s also responsive to T5 heat treatment (artificial aging), which can further enhance its yield strength and hardness, although this may slightly reduce elongation. The iron content is a critical factor; while it helps prevent die soldering, excessive iron can lead to the formation of brittle phases, reducing ductility.

| Property | Typical Value (As-Cast) |

| Ultimate Tensile Strength | 317 MPa (46 ksi) |

| Yield Strength | 165 MPa (24 ksi) |

| Elongation at Break | 3.5% |

| Hardness (Brinell) | 75 HB |

| Shear Strength | 179 MPa (26 ksi) |

Physical Properties & Thermal Conductivity

A key advantage of A360 is its thermal performance. The thermal conductivity of an aluminum casting is heavily influenced by its silicon content. A360’s high Si percentage contributes to a favorable thermal conductivity, making it highly effective at dissipating heat. This is crucial for applications like heat sinks, electronic enclosures, and housings for EV power electronics, where maintaining optimal operating temperatures is essential for performance and longevity.

| Property | Value |

| Density | 2.63 g/cm³ |

| Melting Range | 557 – 596 °C |

| Thermal Conductivity | ~113 W/m-K |

| Electrical Resistivity | 4.8 x 10^-8 Ω·m |

Corrosion Resistance

A360’s low copper content (<0.6%) gives it a significant advantage in corrosion resistance over many other aluminum alloys, particularly the more common A380. Copper can create galvanic cells within the alloy’s microstructure, accelerating corrosion. By minimizing copper, A360 maintains better integrity in corrosive environments, making it highly suitable for marine applications, outdoor enclosures, and components exposed to chemical agents or road salt.

A360 vs. A380: Which Alloy Should You Choose?

While A380 is a versatile, cost-effective workhorse in the die casting industry, A360 offers distinct, superior performance in specific scenarios.

| Feature | A360 Aluminum | A380 Aluminum |

| Corrosion Resistance | Excellent | Fair |

| Strength at High Temps | Superior | Good |

| Pressure Tightness | Excellent | Good |

| Castability | Good, but more challenging | Excellent |

| Cost | Generally higher | More cost-effective |

When to Specify A360 Over A380

Choose A360 when your application’s success depends on:

- Superior corrosion resistance: For parts exposed to saltwater, chemicals, or humid environments.

- High-temperature performance: When the component must maintain its strength under thermal stress.

Excellent pressure tightness: For hydraulic or pneumatic components where leak prevention is critical.

Common Applications of A360 Aluminum Alloy

A360’s low-copper microstructure gives it a significant, measurable advantage. In environments with saltwater spray, road de-icing salts, or industrial chemicals, A360 maintains its structural integrity long after other alloys would show pitting and degradation. This makes it the ideal specification for:

- Automotive & EV: Transmission cases, oil pans, engine components, and housings for motors and inverters where heat dissipation is critical.

- Telecommunications: 5G communication boxes and electronic enclosures that require durability and thermal management.

- Industrial: Hydraulic cylinders, valve bodies, and marine hardware.

- Lighting: LED lamp housings and heat sinks requiring effective thermal dissipation.

Die Casting with A360: Process & Tooling Considerations

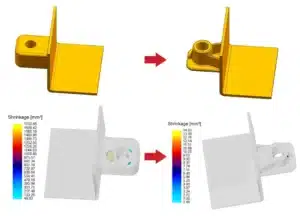

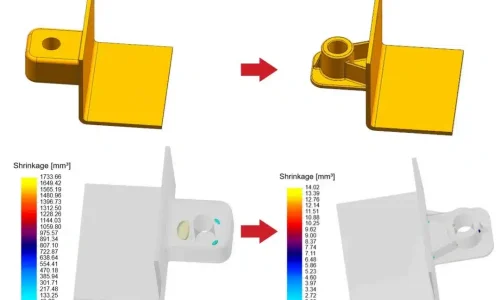

While an excellent alloy, die casting A360 requires precise process control to avoid common defects and manage tooling.

Common Defects & Prevention

- Porosity: Caused by trapped gas or shrinkage. Prevented by optimizing gate/runner design, ensuring proper venting, and controlling mold temperature to promote directional solidification.

- Hot Cracking: Caused by stresses during solidification. Prevented by adjusting die temperature, optimizing part design to avoid sharp corners, and ensuring proper ejection.

- Cold Shuts: Caused by premature solidification. Prevented by increasing melt or die temperature and optimizing injection speed.

Tooling Considerations: Die Soldering

Die soldering (the adhesion of aluminum to the die steel) is a concern with high-silicon alloys. While the iron content in A360 helps mitigate this, proper die maintenance, the use of high-quality tool steels (like H13), and appropriate die coatings or surface treatments are essential for maximizing tool life and ensuring consistent part quality.

Surface Finishing: Maximizing A360’s Durability

While A360’s inherent corrosion resistance is excellent, surface finishing can elevate its performance by providing enhanced wear resistance, a final barrier against the elements, or specific aesthetic properties.

- Anodizing (Type II & Type III): Anodizing creates a hard, ceramic-like layer of aluminum oxide on the surface. For A360, this process provides exceptional scratch and wear resistance. However, due to the alloy’s high silicon content, the resulting finish is typically a dark, charcoal gray. This makes it ideal for functional applications where durability is paramount, but less so for purely cosmetic ones.

- Powder Coating: This is a highly durable and decorative option. A dry powder is electrostatically applied and then cured under heat, forming a tough, uniform skin. It provides an excellent barrier against corrosion, chemicals, and impacts, and is available in a vast range of colors and textures.

- Chromate Conversion Coating (e.g., Alodine/Iridite): This chemical treatment creates a thin, inert film on the aluminum surface. It provides good corrosion resistance on its own and serves as an excellent primer that promotes adhesion for subsequent painting or powder coating.

- E-Coating (Electrophoretic Painting): E-coating uses an electrical current to deposit paint, resulting in a uniform, thin, and highly corrosion-resistant finish. It excels at covering complex shapes and internal cavities, providing comprehensive protection.

FAQs

For applications demanding superior corrosion resistance and high-temperature strength, A360 aluminum alloy is an excellent choice. Ready to discuss your next die casting project? Contact our engineering team for a free quote and design analysis.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.