While A380 is often the default, general-purpose die-casting alloy, ADC12 is the go-to choice for parts with intricate details and thin walls. Valued for its exceptional fluidity and dimensional stability, ADC12 provides an excellent combination of castability and mechanical properties, making it one of the most widely used alloys globally. It is the preferred material when complete mold filling in complex geometries is the primary design challenge.

This technical guide provides a complete overview of ADC12 aluminum, including its international equivalents, detailed property tables with design implications, direct comparisons to other popular alloys, and a practical checklist for DFM and defect prevention.

What is ADC12? (JIS) and Its Equivalents

ADC12 is a Japanese Industrial Standards (JIS) designation. However, its formulation is globally recognized and specified under several other international standards. For engineers and sourcing managers, understanding these equivalents is crucial for navigating global supply chains. The most common equivalent is A383 under the North American ANSI/AA standards.

A383 (ANSI/AA) & AC-46100 (EN) Comparison Chart

This “cross-standard comparison card” helps you map ADC12 to its international counterparts.

| Standard | Designation | Notes |

| JIS (Japan) | ADC12 | The baseline designation in this article. |

| ANSI/AA (USA) | A383.0 | The most common equivalent in North America. |

| EN (Europe) | EN AC-46100 | European Norm designation. |

| ISO | AlSi11Cu2(Fe) | International Organization for Standardization. |

| UNS | A03830 | Unified Numbering System. |

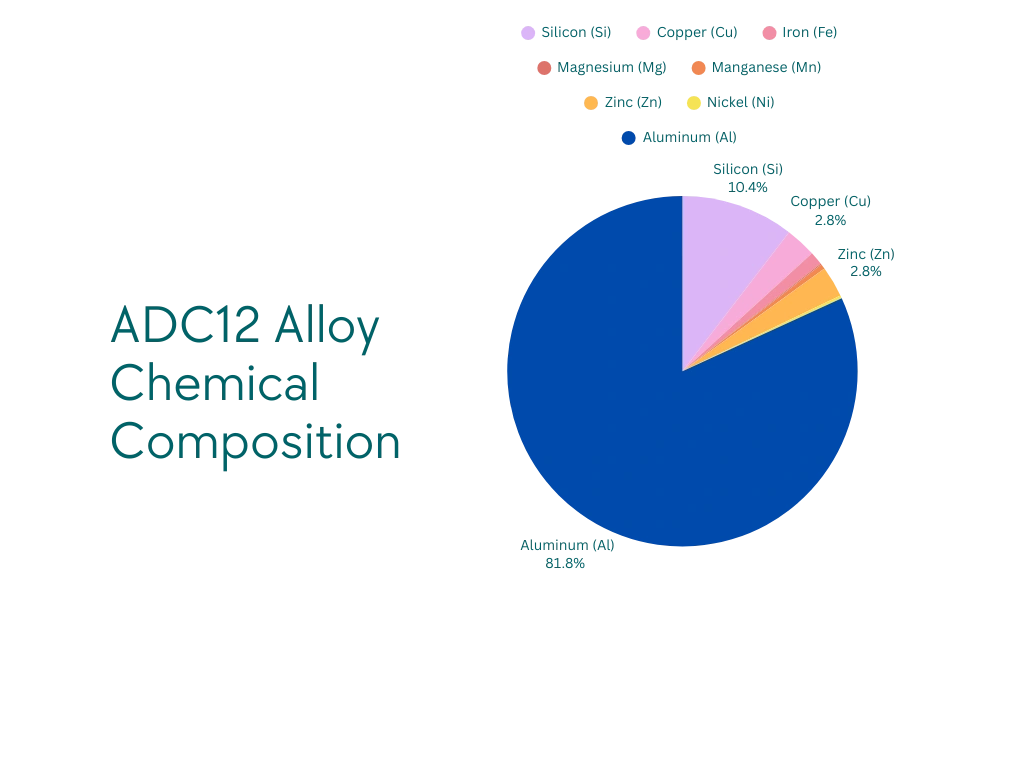

ADC12 Alloy Chemical Composition

ADC12’s excellent castability stems from its high silicon (Si) content, while its copper (Cu) content enhances its strength. However, this higher copper level also means its corrosion resistance is lower than that of alloys like A360.

| Element | Composition (%) | Design Implication |

| Silicon (Si) | 9.5 – 11.0 | Key Element: Provides excellent casting fluidity for filling thin walls and complex features. |

| Copper (Cu) | 2.0 – 3.0 | Increases hardness and mechanical strength, but reduces ductility and corrosion resistance. |

| Iron (Fe) | ≤1.3 | Controlled to prevent die soldering (sticking). Lower levels improve ductility. |

| Magnesium (Mg) | ≤0.1 | Minor additions improve strength. |

| Manganese (Mn) | ≤0.5 | Improves strength and counters the negative effects of iron. |

| Zinc (Zn) | ≤3.0 | – |

| Nickel (Ni) | ≤0.3 | – |

| Aluminum (Al) | Balance | – |

Mechanical & Physical Properties

The following tables provide typical values for high-pressure die-cast (HPDC) ADC12 components and explain what these numbers mean for your product’s design.

Mechanical Properties

| Property | Typical Value | What This Means for Your Design |

| Ultimate Tensile Strength (σb) | 310 MPa (45 ksi) | Good strength for housings and structural parts not subjected to extreme loads. |

| Yield Strength (σ0.2) | 150 MPa (22 ksi) | The stress level at which the part will begin to permanently deform. |

| Elongation (A) | ~3.5% | Critical Insight: Low ductility means the material is brittle. Design features like snap-fits or thin cantilevered hooks with generous fillets to prevent them from fracturing under strain. |

| Hardness (Brinell) | ~75 HB | Offers moderate wear and indentation resistance for typical applications. |

Physical Properties

| Property | Typical Value | What This Means for Your Design |

| Density (ρ) | 2.74 g/cm³ | A lightweight material suitable for applications where weight is a consideration. |

| Thermal Conductivity (λ) | ~96 W/m·K | Critical Insight: Moderate thermal conductivity. For heat sink applications, ensure sufficient surface area through fins and consider wall thickness carefully in thermal simulations. Proper surface finish (e.g., powder coating) also impacts thermal performance. |

| Coefficient of Thermal Expansion | 21.1 µm/m·°C | Important for assemblies with other materials (like steel inserts) to manage stress during temperature changes. |

When to Choose ADC12 vs. Other Alloys

Making the right alloy choice upfront prevents costly tooling changes and production issues. Use this guide to decide if ADC12 is the right fit.(Decision Logic: If your primary challenge is filling a complex, thin-walled geometry, start with ADC12. If the part is simpler and needs balanced properties, use A380. If corrosion resistance is paramount, look to A360.)

vs. A380 (Complex Thin-Wall Filling vs. General Default)

- Choose ADC12 When: Your design has walls thinner than 1.5 mm, sharp details, or a high length-to-thickness ratio. ADC12’s superior fluidity ensures these features are fully formed, reducing the risk of misruns and cold shuts. As noted by industry experts like Gabrian International, it is the preferred alternative to A380 for complex parts.

- Choose A380 When: Your part has a more uniform and thicker geometry. A380 offers a better all-around balance of mechanical properties, castability, and cost, making it the industry’s workhorse for a vast range of applications.

vs. A360 (Castability vs. Corrosion Resistance)

- Choose ADC12 When: Castability and intricate detail are the main priorities. The part will operate in a controlled environment where corrosion is not a major concern.

- Choose A360 When: The component will be exposed to harsh environments (e.g., marine, outdoor) or operate at high temperatures. A360’s very low copper content gives it far superior corrosion resistance, but it is less fluid and more challenging to cast than ADC12.

vs. A413 (General Fluidity vs. Pressure Tightness)

- Choose ADC12 When: You need excellent fluidity for general complex parts like electronic housings or motor bodies.

- Choose A413 When: The single most critical requirement is leak-proof performance (pressure tightness). A413 is a eutectic alloy with minimal shrinkage, making it ideal for hydraulic components, valve bodies, and pressure vessels.

vs. B390 (General Purpose vs. High Wear Resistance)

- Choose ADC12 When: Your application requires a good balance of castability for complex shapes, decent strength, and cost-effectiveness. Standard wear resistance is sufficient.

- Choose B390 When: The single most important property is extreme wear and abrasion resistance. B390 is a hypereutectic alloy with very high silicon content (~17%), making it ideal for pistons, cylinders, and compressor parts. However, this comes at the cost of being very difficult to cast and machine.

| Requirement / Scenario | Prefer | Why |

| Intricate / thin-wall features; better die filling | ADC12 (A383/AC-46100) | Selected over A380 when feature complexity and fill are critical. |

| General-purpose balance (cost/strength/castability) | A380 | The broad “default” for many HPDC parts when geometry is less demanding. |

| Higher corrosion resistance / better elevated-temperature behavior | A360 | Improves corrosion/high-temp performance vs. A380/ADC12 at some cost to castability. |

| Strict pressure-tight housings | A413 | Known for excellent pressure tightness with proper tooling and process control. |

| Very high wear resistance | B390 | High hardness/wear; low ductility—design carefully. |

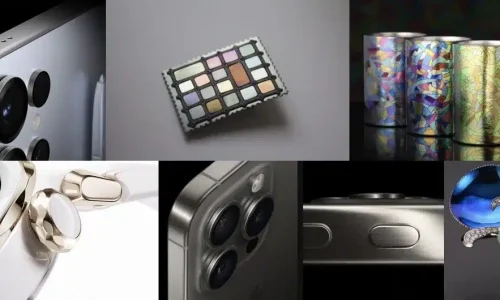

Surface Finishing on ADC12

The right finish can protect against wear, provide cosmetic appeal, or improve thermal performance.

- Powder Coating / Painting → Recommended Path

ADC12 is an excellent substrate for these finishes. A thorough multi-stage pretreatment (cleaning and chromate or non-chrome conversion coating) is essential to ensure maximum adhesion and long-term performance. - Anodizing → Functional Only, Not Decorative

ADC12 can be given a functional hardcoat anodize (Type III) for wear resistance. However, its high silicon content causes the finish to turn a dark gray or mottled color. Decorative anodizing (Type II) is not recommended, as achieving a consistent, aesthetically pleasing appearance is nearly impossible. Always run samples before committing to production. - Pre-treatment: Manage porosity exposure and adhesion (e.g., blasting, conversion coatings) in concert with your casting and machining routes.

DFM & Defect Prevention for ADC12

Good design practices are key to leveraging ADC12’s strengths and avoiding common casting defects.

DFM Checklist

- Thin Walls: Design walls to be as uniform as possible. While ADC12 can fill walls down to ~1.0 mm, maintaining consistency is key.

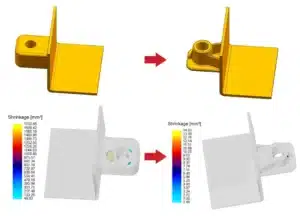

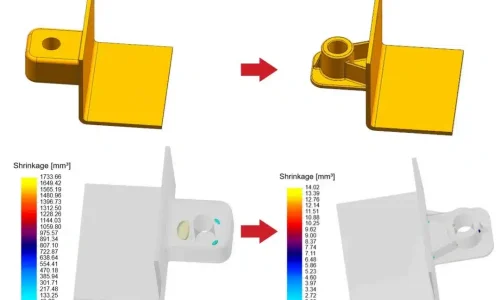

- Rib-to-Wall Ratio: Ribs should be 0.5–0.7 times the thickness of the wall they are attached to, preventing shrinkage voids at the junction.

- Fillets (Internal Radii): Use generous fillets of at least 0.5–1.0 mm (or 0.5x wall thickness) to improve metal flow and reduce stress concentrations that can lead to hot tearing.

- Draft Angles: Apply a minimum of 1° of draft to all surfaces parallel to the die opening direction; 2° is safer and improves part ejection.

Process & Defect Countermeasures

- Gating, Venting, and Overflows: These must be carefully designed (often with Moldflow simulation) to ensure smooth, rapid filling while allowing trapped air to escape, preventing gas porosity.

- Vacuum HPDC: For critical parts, using a vacuum to evacuate air from the die cavity before injection dramatically reduces porosity and improves mechanical properties.

- Die Thermal Management: Precise control of die temperature is crucial for preventing premature solidification (cold shuts) and reducing thermal stress that causes hot tearing.

Common Defects & Their Solutions

- Misruns / Cold Shuts: Incomplete filling of the mold.

- Solution: Improve fluidity by adjusting process parameters (metal/die temp, injection speed); verify DFM for thin sections and flow paths.

- Gas Porosity: Trapped air or gas bubbles.

- Solution: Optimize vents and overflows; use vacuum HPDC; ensure clean, dry ingot.

- Hot Tearing: Cracks that form as the part cools.

- Solution: Add generous fillets in DFM; optimize die cooling to ensure uniform solidification.

Applications & Case Notes

ADC12 is used across industries for parts that require intricate shapes and good stability.

- Telecommunications Housings: The excellent fluidity allows for casting thin, complex fins for heat dissipation, while its stability is key for achieving IP ratings for water and dust proofing. Design must account for CNC tapping of holes for threaded inserts.

- Automotive Components: Used for engine parts, transmission cases, and sensor housings that have complex geometries but are not subjected to the highest structural loads.

- Power Tool Casings: ADC12 can form the complex, ergonomic shapes of drill and saw housings, which must be lightweight yet durable enough to withstand job site impacts. Design should include reinforcing ribs and solid bosses for mounting points.

FAQs

Get a Part Review

Get a Free Part Review — precision from design to delivery

Submit your 3D model, performance targets, and production volume. Our engineers will compare ADC12, A380, A360, and A413 and provide a comprehensive report with mold flow analysis and defect avoidance recommendations, including a downloadable DFM checklist to optimize your design.

Aluminum Die Casting Services

Learn more about our aluminum high pressure die casting services in China.