Wondering how to give your aluminum products a finish that’s both incredibly durable and visually striking? Clear anodized aluminum—an electrochemical process that grows a hard, transparent aluminum-oxide layer right from the metal itself—is your best choice.

This guide explores clear anodized aluminum, an electrochemical process that grows a hard, transparent layer of aluminum oxide directly from the metal itself. Unlike paint, it doesn’t coat the surface—it becomes part of it. Discover why this makes it one of the most durable and aesthetically unique finishes available.

What Is Clear Anodized Aluminum?

Electrochemical Basis: From Aluminum to Alumina (Al2O3)

Clear anodized aluminum is defined as aluminum material that has undergone an electrochemical process to grow a thick, controlled, and transparent layer of aluminum oxide (Al2O3) directly on its surface. This process accelerates and enhances the natural passivation layer that aluminum forms in the atmosphere.

The core step of the process involves making the aluminum part the anode in an electrolytic cell, typically placed in a sulfuric acid electrolyte. When a direct current is passed through, oxygen ions from the electrolyte combine with the aluminum atoms at the surface, forming the Al2O3 layer. This method differs from simple surface coating; it is a conversion process that transforms the base metal itself into a functional ceramic layer.

Nature of the Anodic Layer: An Integral, Crystalline, and Porous Surface

Crucially, the anodic layer is not an applied coating; it is integral to the metal substrate, growing directly from it. This is why it does not chip, flake, or peel like paint. This fundamental characteristic is the root of its superior durability over all other surface treatments.

Microstructurally, the oxide layer consists of two parts: a very thin, non-porous barrier layer at the bottom, upon which grows a much thicker, highly porous structure. This porous structure is composed of densely packed hexagonal honeycomb-like cells, each with a central pore.

Microstructure Deep Dive: The crystallographic structure of the oxide layer is complex. Although the oxide layer formed under conventional anodizing conditions is often described as amorphous, it actually contains crystalline phases. Under specific conditions, it can form nanostructured γ-Al₂O₃ (gamma-alumina). The thermodynamically stable phase α-Al₂O₃ (corundum), known for its extreme hardness, typically requires very high temperatures or special processes like Plasma Electrolytic Oxidation (PEO) to form. The final structure is a mixture of these phases, which directly impacts the material’s final hardness and durability.

Visual and Tactile Characteristics: The Meaning of “Clear”

“Clear” anodizing refers to the production of a transparent, colorless anodic layer (Class 1) without the use of dyes. This treatment preserves and enhances the natural metallic luster and texture of the base aluminum, presenting a silver or natural metallic appearance. The final look can be specified as matte or high-gloss depending on pre-treatment steps like etching or polishing.

This translucency is a key aesthetic distinction from opaque finishes like paint, as it allows the texture and character of the base metal to show through.

Common Aluminum Alloys

The final appearance and quality of the anodized finish are highly dependent on the aluminum alloy used. While most alloys can be anodized, some are better suited for achieving a consistent, high-quality clear finish.

- 6061 and 6063 Alloys: Part of the 6xxx series, these alloys contain magnesium and silicon and are excellent for anodizing. They produce a strong, clear, and protective oxide layer, making them ideal for both structural and architectural applications. 6063 is often called “architectural aluminum” for its aesthetically pleasing results.

- 5052 and 5005 Alloys: These 5xxx series alloys, alloyed with magnesium, also produce a strong, clear oxide layer and are considered great for anodizing. For the best color consistency, 5005 is often recommended for sheet applications to match 6063 extrusions.

- A380 Alloy: This is a very common die-casting alloy known for its good mechanical properties and fluidity, which allows for the casting of intricate parts. However, its high silicon content makes it more difficult to anodize compared to wrought alloys like 6061. The silicon can disrupt the uniformity of the oxide layer, making it a less ideal candidate where a pristine cosmetic finish is the primary goal.

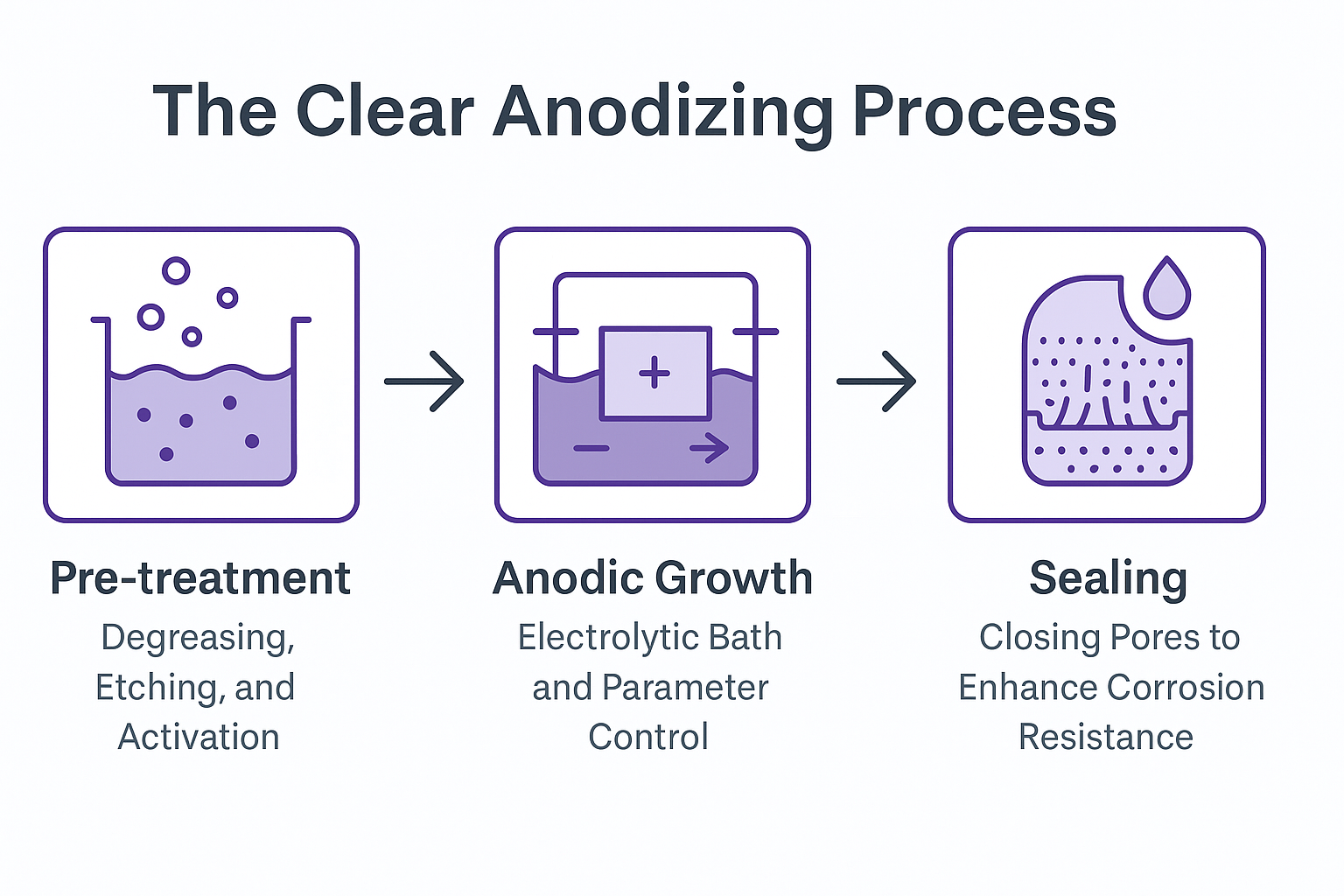

The Clear Anodizing Process

The creation of a high-quality clear anodized finish is a multi-stage process where each step is critical to the final outcome.

Pre-treatment: Degreasing, Etching, and Activation

The foundation of a quality anodized finish is a perfectly clean and prepared surface.

- Cleaning/Degreasing: Parts are first immersed in a non-etching, alkaline detergent bath (around 63°C / 145°F) to remove oils, grease, and other shop contaminants.

- Rinsing: After each chemical step, parts are thoroughly rinsed, often with deionized water, to prevent cross-contamination between tanks.

- Etching/Acid Pickling: Parts are placed in a chemical bath, typically a caustic soda (sodium hydroxide) solution, to remove the thin, naturally occurring oxide layer and a small amount of the surface metal. This step helps eliminate minor surface defects and creates a uniform matte appearance.

- Desmutting/Activation: After etching, a residue of alloying elements (smut) can remain on the surface. This is removed by dipping the part in an acid bath (e.g., nitric acid), which leaves a clean, chemically active surface ready for anodizing.

Anodic Growth: Electrolytic Bath and Parameter Control

This is the core electrochemical step where the oxide layer is formed.

- Electrolytic Bath: The aluminum part is immersed in an electrolyte, most commonly a sulfuric acid solution with a concentration of around 15%.

- Electrolysis: The aluminum part is made the anode (+) in the electrolytic cell, and a direct electrical current (DC) is passed through the solution. The electrical charge causes oxygen ions from the electrolyte to bond with the aluminum atoms on the surface, forming a dense, porous layer of aluminum oxide (Al2O3).

Sealing: Closing Pores to Enhance Corrosion Resistance

This final step is absolutely essential for the performance and longevity of the finish. The newly formed anodic layer is highly porous, and these pores must be closed to prevent staining and provide maximum corrosion resistance. This is typically achieved through a hydrothermal treatment, such as immersion in boiling deionized water or a nickel acetate solution, which hydrates the aluminum oxide, causing it to swell and seal the pores.

Key Benefits of Clear Anodized Aluminum

Clear anodizing imparts a range of functional and aesthetic benefits that make it a superior choice for many applications.

- Corrosion Resistance: The sealed, non-porous oxide layer provides a robust barrier against moisture, salt, and other corrosive elements. High-quality clear anodized finishes can meet demanding salt spray test requirements, with MIL-A-8625 Type II finishes capable of withstanding over 336 hours, and architectural Class I finishes rated for 3,000 hours.

- Increased Wear and Hardness: The anodizing process creates a surface layer of aluminum oxide, a ceramic material that is significantly harder than the base aluminum. This provides excellent resistance to scratches, abrasion, and general wear, making it ideal for high-traffic areas and frequently handled components.

- Excellent Aesthetic Effect: Clear anodizing preserves and enhances the natural metallic beauty of aluminum, providing a clean, uniform, and professional finish. The resulting appearance is typically a silver or natural gray color, which can have a matte or glossy texture depending on the pre-treatment.

- Environmental and Safety Compliance: The anodizing process is considered environmentally friendly as it does not produce volatile organic compounds (VOCs) or use heavy metals. The resulting finish is non-toxic, heat-resistant, and fully recyclable. Standard clear anodizing processes (without dichromate sealing) are compliant with RoHS and REACH regulations.

Non-anodized vs. Anodized Aluminum

To fully appreciate the benefits of anodizing, it’s useful to compare it with non-anodized (or “raw” / “mill finish”) aluminum. Non-anodized aluminum is the metal in its basic state after manufacturing, protected only by a very thin, naturally occurring oxide layer that is pliable and easily damaged. Anodizing dramatically enhances these natural properties.

- Durability and Hardness: Anodized aluminum is significantly harder and more resistant to scratches and wear. The anodizing process creates a thick, robust oxide layer that is much stronger and more durable than the soft surface of raw aluminum.

- Corrosion Resistance: While standard aluminum has some natural corrosion resistance, anodized aluminum is far superior. The engineered anodic layer provides a much thicker, more consistent barrier against moisture, salt, and other corrosive elements.

- Appearance and Finish: Mill finish aluminum often has a dull, matte, and sometimes inconsistent surface. Clear anodizing provides a much smoother, more uniform, and aesthetically refined finish that enhances the metal’s natural luster.

- Adhesion and Lubrication: The porous surface of an unsealed anodized layer creates an excellent base for primers, glues, and paints, offering superior adhesion compared to the smooth surface of standard aluminum. This porosity also allows for better retention of lubricating oils.

- Cost and Application: Non-anodized aluminum is less expensive due to the lack of additional processing. It is suitable for low-budget projects or applications with minimal exposure to wear or corrosive elements. Anodized aluminum is preferred for any application requiring long-term durability, a consistent aesthetic appearance, and low maintenance.

Typical applications for Aluminum Anodizing

The unique combination of durability, light weight, and aesthetics makes clear anodized aluminum a preferred material across numerous industries.

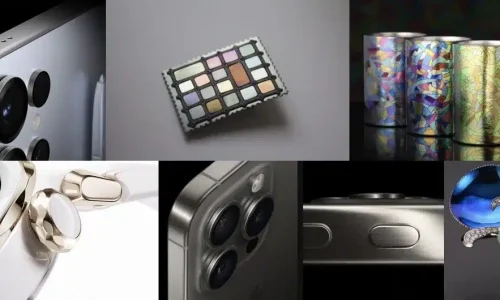

- Electronics and Consumer Products: Widely used for the housings and enclosures of high-end electronics like laptops, smartphones, cameras, and audio equipment, where a sleek, modern, and scratch-resistant finish is desired.

- Automotive and Transportation: Found in decorative interior and exterior trim, emblems, wheel covers, and other components that require a blend of corrosion resistance and high-quality appearance.

- Aerospace and Precision Instruments: Essential for aircraft structural components, panels, and fittings where a high strength-to-weight ratio, extreme durability, and reliable corrosion protection are critical. It is also used for heat sinks and guide rails.

- Architecture and Decoration: A staple for building exteriors, including curtain walls, window and door frames, roofing systems, and decorative facades. Its resistance to UV degradation and weather makes it ideal for long-lasting architectural applications.

Design & Manufacturing Considerations

To achieve a successful anodized finish, several factors must be considered during the design and manufacturing stages.

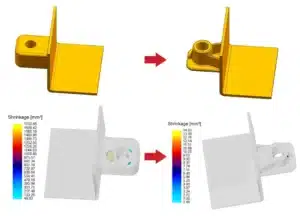

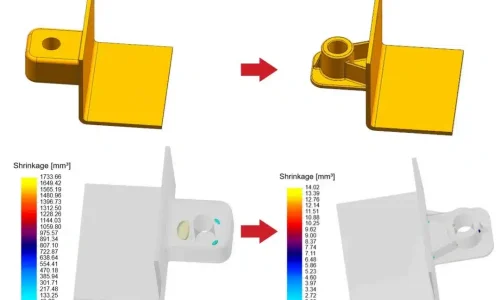

- Geometric Shape: The uniformity of the anodic layer can be affected by the part’s geometry. Deep grooves, sharp inside corners, and blind holes can experience variations in current density, leading to thinner or inconsistent coatings in those areas. For hollow parts, ventilation holes are necessary to allow process liquids to drain and prevent gas from being trapped.

- Fixturing and Racking: Parts must be held on conductive racks (typically aluminum or titanium) to ensure a consistent electrical current throughout the process. The points where the rack touches the part will not be anodized, so the location of these contact marks must be considered in the design, preferably on non-critical surfaces.

- Material Tolerances and Deformation: The anodizing process is a conversion coating, meaning it both penetrates the substrate and builds up on the surface. For a typical Type II anodize, approximately two-thirds of the thickness penetrates the surface, while one-third builds up. This dimensional change, though small (typically 5 to 25 microns), must be accounted for in parts with tight tolerances.

- Compatibility with Subsequent Processes:

- CNC Machining: It is almost always preferable to perform all CNC machining before anodizing. Machining after anodizing will remove the protective layer, exposing the raw aluminum.

- Laser Engraving: Laser engraving works by ablating or bleaching the anodized layer, exposing the bare aluminum underneath to create a high-contrast, permanent mark. Both CO2 and fiber lasers can be used effectively on anodized aluminum.

- Silk Screening: Inks can be applied to the anodized surface via silk screening. For maximum durability, a special process can be used where dyes are impregnated into the unsealed anodic pores before the final sealing step, making the graphic an integral part of the finish.

How to Clean Anodized Aluminum

Although anodized aluminum is extremely durable, regular cleaning is essential to preserve its appearance and integrity, especially when exposed to contaminants. A cleaning schedule of at least once per year is recommended, with more frequent cleaning in harsh coastal or industrial environments.

Routine Cleaning Guide

For light soiling, a simple cleaning process is effective.

- Rinse: Flush the surface with clean water using moderate pressure to remove any loose dirt and debris.

- Wash: Gently clean the surface with a soft cloth, sponge, or soft-bristled brush using a mild, pH-neutral soap or detergent (pH 6-8). A good rule of thumb is that any cleaner safe for bare hands is generally safe for anodized aluminum.

- Rinse Again: Thoroughly rinse the surface with clean water, working from the top down to prevent residue from running onto cleaned areas.

- Dry: Wipe the surface dry with a soft cloth to prevent water spots and streaks.

Handling Stubborn Stains and Scuffs

For more difficult stains, slightly more aggressive methods can be used.

- Scuff Marks: Minor scuff marks can often be removed by gently rubbing the area with a mild abrasive pad in the direction of the metal grain.

- Grease and Sealants: To remove grease or sealant residue, a solvent no stronger than mineral spirits or denatured alcohol may be used.

What to Avoid

Using the wrong products or techniques can permanently damage the anodized finish.

- Harsh Chemicals: Never use strong acidic or alkaline cleaners (pH outside the 6-8 range). Cleaners containing chlorine should also be avoided.

- Abrasive Tools: Do not use harsh abrasive materials like steel wool, sandpaper, or hard-bristled brushes, which can scratch the finish.

- Hot Surfaces: Avoid cleaning surfaces when they are hot, as this can cause an uneven appearance.

- Always Test First: Before using any new cleaning product, test it on a small, inconspicuous area to ensure it does not cause discoloration or damage.

For long-term protection, a layer of wax or a specialized sealant can be applied after cleaning to provide an additional protective barrier. In cases of severe oxidation or damage, professional restoration services are recommended.

Conclusion

Clear anodized aluminum stands as a premier surface finish, offering an unparalleled combination of durability, corrosion resistance, and aesthetic quality. Because the protective layer is grown from the aluminum itself, it delivers a finish that will not chip, peel, or flake, ensuring exceptional longevity with minimal maintenance. Its clean, metallic appearance is highly valued in applications ranging from architecture and automotive to consumer electronics and aerospace. Furthermore, its compliance with environmental standards like RoHS and REACH makes it a responsible choice for sustainable manufacturing.

By understanding the interplay between alloy selection, process control, and design considerations, manufacturers and designers can fully leverage the benefits of this remarkable technology.

For more information, to request a sample of our clear anodized finishes, or to discuss your specific project needs with our engineering team, please do not hesitate to contact us. We are here to provide the technical support you need to bring your design to life.